Vacuum Plating In China | Gold & Chrome Thin Film Coating Metallization

Surface Treatment After Parts Machining: Vacuum Plating.

|

Vacuum plating is a physical deposition phenomenon. That is, under the vacuum state, argon gas is injected, and the argon gas hits the target, and the separated molecules of the target are adsorbed by the conductive goods to form a uniform and smooth surface layer. PTJ Shop's Partner have high volume job shop for coating, plating, and creation of specialty finishes. Finishing methods used include vacuum metallizing, sputtering, cathodic arc deposition, reactive PVD, electro-plating, precious metal plating, antiquing, spray coating, and powder coating. Applications include cosmetics, lighting, electronics, plumbing, hardware, medical, and transportation. Substrates coated include most plastics, metals, and glass. ISO 9001:2015 certified vacuum plating services including ion plating. Materials include gold, platinum, chromium, titanium, copper, aluminum & nickel. Call us! |

|

|

|

|

|

|

|

|

|

View PTJ Shop vacuum plating Case Studies,Contact our custom services machinists today to discuss the specifics of your complex parts. |

|

|

|

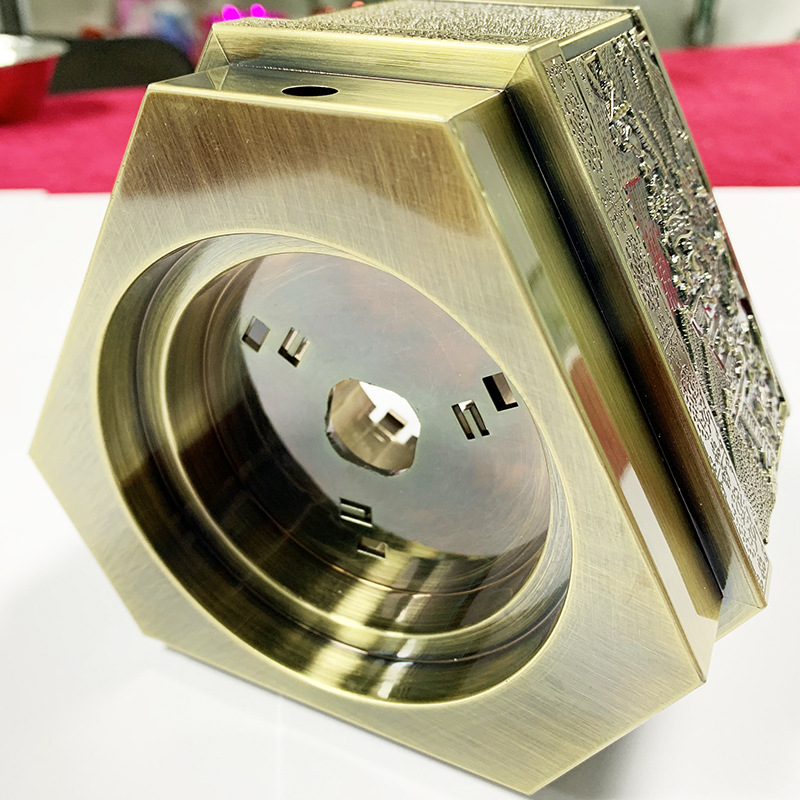

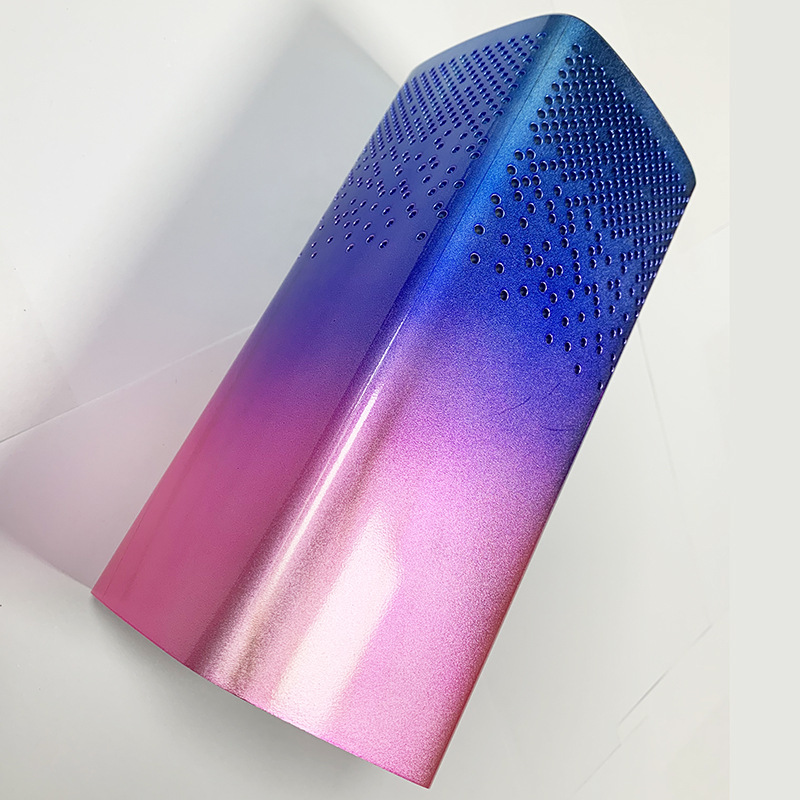

| Bronze Brushed And Vacuum Plating | Vacuum Plating Gradient Color Electronic Parts | Vacuum Plated Plastic Parts |

Features of vacuum plating

- ▶ The metal film layer obtained by vacuum coating is very thin (usually 0.01 ~ 0.1um), which can strictly reproduce the shape of the surface of the beer.

-

▶ The working voltage is not very high (200V), it is easy to operate, but the equipment is expensive.

- ▶ The volume of the evaporation pot is small, the number of plating parts is small, and the production efficiency is low.

- ▶ It is limited to metal (such as aluminum, silver, copper, gold, etc.) plating lower than the melting point of tungsten wire.

-

▶ The requirements for the surface quality of the plated parts are high. Generally, a primer is required to make up for the surface defects of the workpiece before plating.

- ▶ vacuum coating can be coated with a variety of plastics such as ﹕ ABS, PE, PP, PVC, PA, PC, PMMA and so on.

View more machining parts on our Gallery Page

Vacuum plating with small and high volume custom injection molding capabilities and capacities from 28 tons to 1500 tons. Products range from small precise automotive and cosmetic pieces to large molded parts up to 15 lbs. in weight. Other services include pad printing, hot stamping, painting and finishing, assembly, sonic welding and warehousing.Capabilities include thin film coating, sputtering & physical vapor & vacuum deposition. Various applications include biomedical, satellites, electronics & particle physics apparatus.-

▶ Treatments : heat treating with low pressure vacuum carburizing for hardening & carburizing bearing steel & aerospace components.

-

▶ Hot Zones Specifications : 24 in. x 24 in. x 36 in. with temperature ratings of 2400 degrees Fahrenheit & 1500 lb. gross loading capacities.