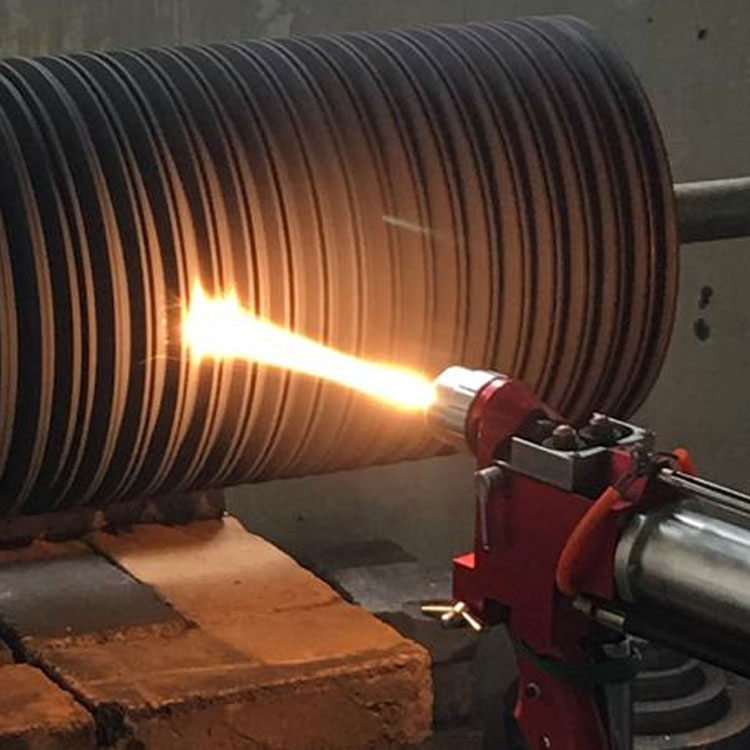

Thermal Spraying Technology | HVOF Thermal Spraying Services

Surface Treatment After Parts Machining: Thermal Spraying.

|

Thermal Spraying involves melted or heated materials that are accelerated, then collided and bonded mechanically to the target surface. A wire or powder feedstock, usually metal or ceramic, is melted by injecting it into a flame, electrical arc, or plasma stream. Engineers sometimes specify this process when added friction is a desirable characteristic. It is also commonly used on larger structural objects for protection against high temperatures, such as a thermal barrier coating for exhaust heat management. PTJ Shop Supply high velocity oxygen fuel thermal spraying services. Capabilities include metal plating, finishing, repair and remanufacturing, metalworking, painting, plastic media and sand blasting, screen printing, engraving and coating. Suitable for aircraft/aerospace, electronics, industrial and commercial applications.call us! |

|

|

|

|

|

|

|

|

|

View PTJ Shop Thermal Spraying,Contact our custom services machinists today to discuss the specifics of your complex parts. |

|

|

|

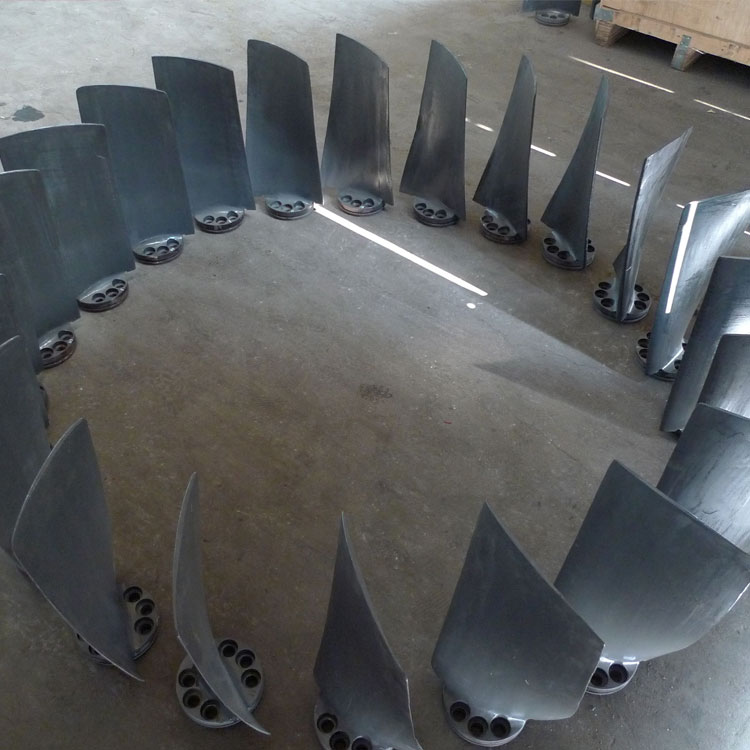

| Thermal Spraying Wind Turbine Blades | Crankshaft Thermal Spray Repair | Quality China Thermal Spraying Technology |

Other Method

- ▶ Flame Spraying

- ▶ Plasma Spraying