Surface Hardening Services | General Surface Hardening Methods

Surface Treatment After Parts Machining: Surface Hardening

|

Surface Hardening is a process of metal surface alteration, such as carburizing, nitriding, and induction hardening of steel. The processes improve anti-wear properties and fatigue strength by altering metal surface properties. PTJ Shop Supply Hardening services for tool steel and various alloy components. Capabilities include induction and flame hardening using open or sealed furnaces. Open pit furnace capacities include up to 144 in. dia. x 96 in. height. Induction hardening is suitable for steel parts and other alloys with carbon content ranging from 0.40 percent to 0.45 percent and alloy steels such as 4320, 8620 and 9310 for applications including bearing races, gears, pinion shafts, crane wheels and treads and threaded pipes used for oil patch drilling. Flame hardening is suitable for selective hardening of flat surfaces such as flat wear plates and knives.call us |

|

|

|

|

|

|

|

|

|

View PTJ Shop Surface Hardening Case Studies,Contact our custom services machinists today to discuss the specifics of your complex parts. |

|

|

|

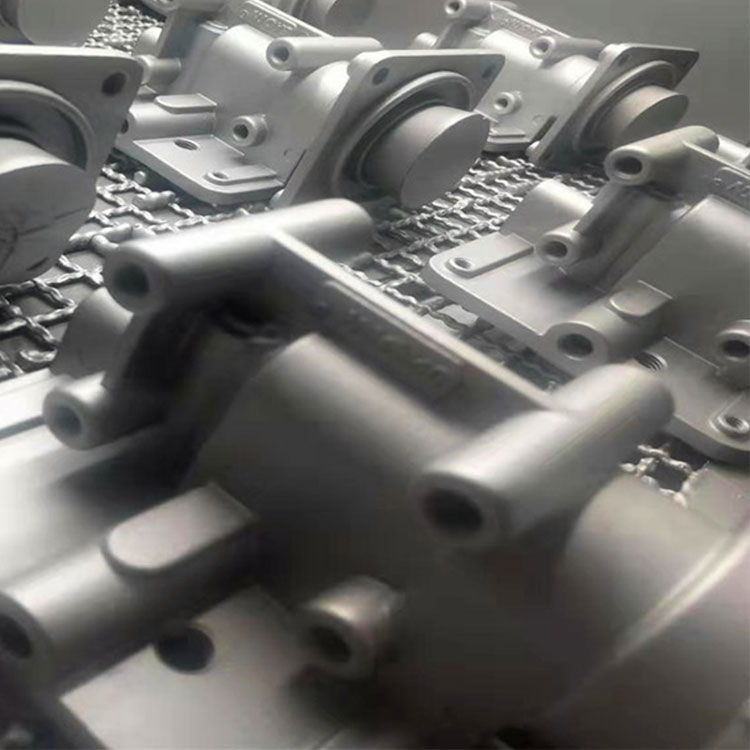

| Plastic Surface Hardening Services | Die-Casting Surface Hardening Services | Steel Surface Hardening Services |

Surface Hardening Capabilities

- ▶ Laser Cutting

-

▶ 5 Axis Tube Cutting

- ▶ Stamping

- ▶ CNC Plasma And Acetylene Cutting