CHINA STAMPING SERVICES FOR NON-STANDARD CUSTOM INDUSTRY

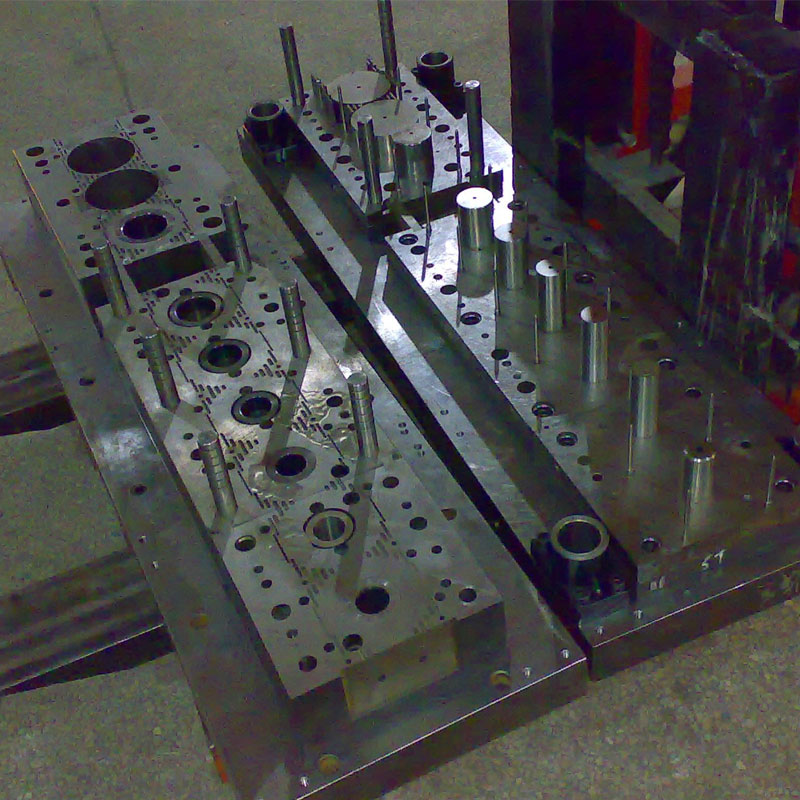

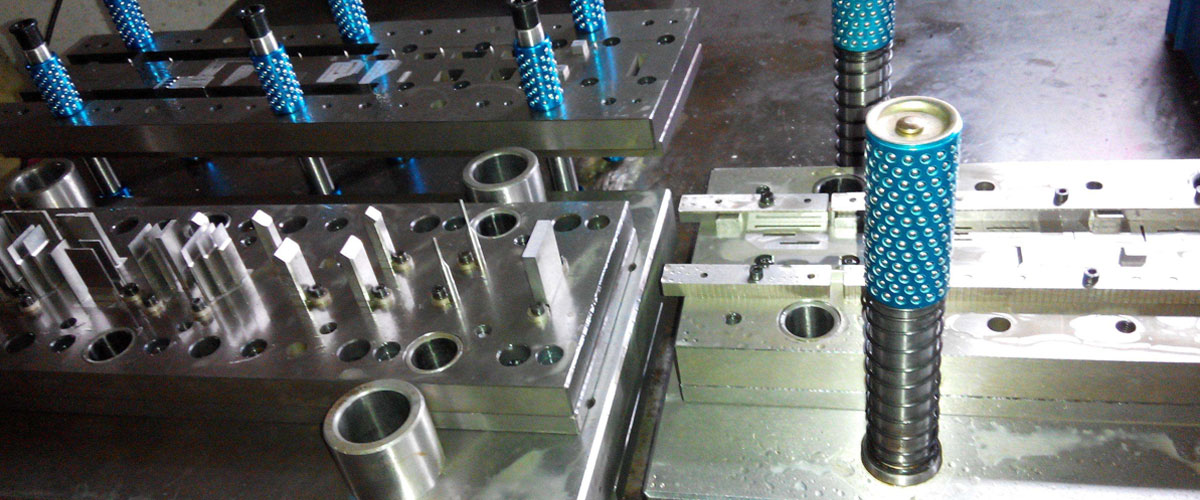

Our large library of more than 180,000 tooling fixtures is available for use and customization—at little to no cost to the customer.

|

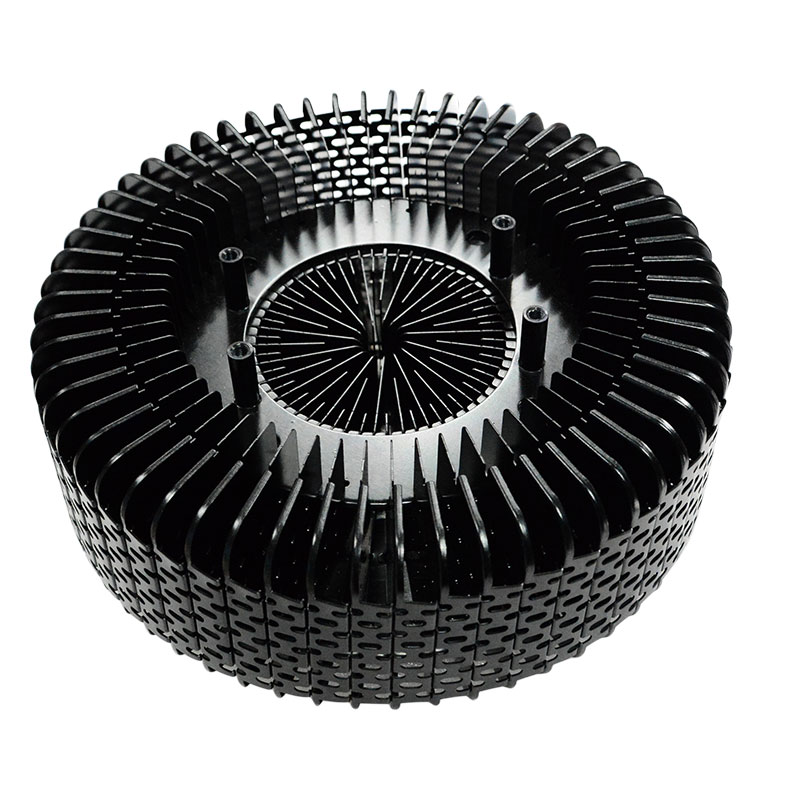

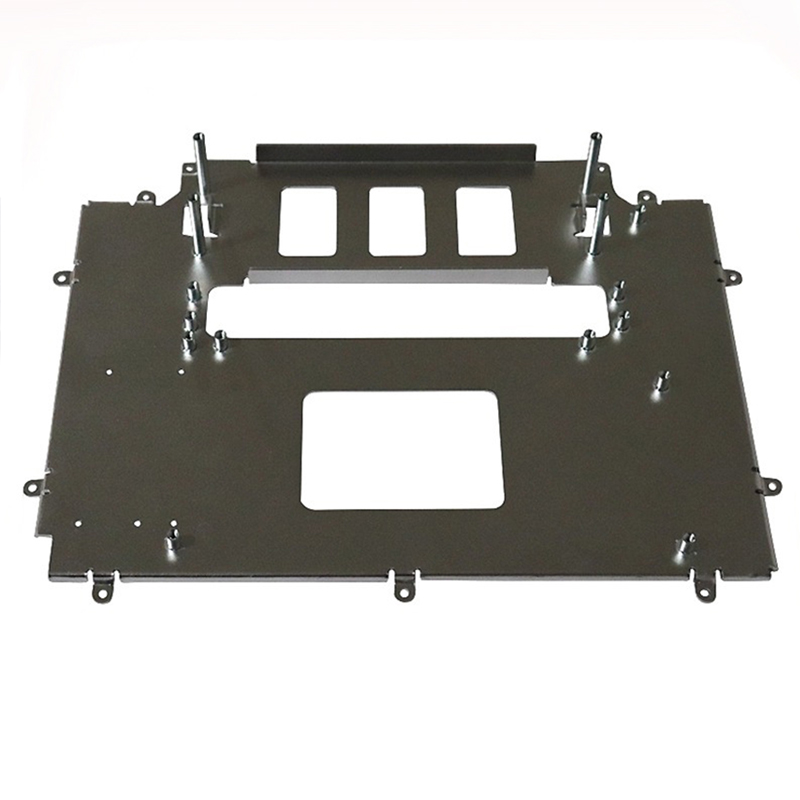

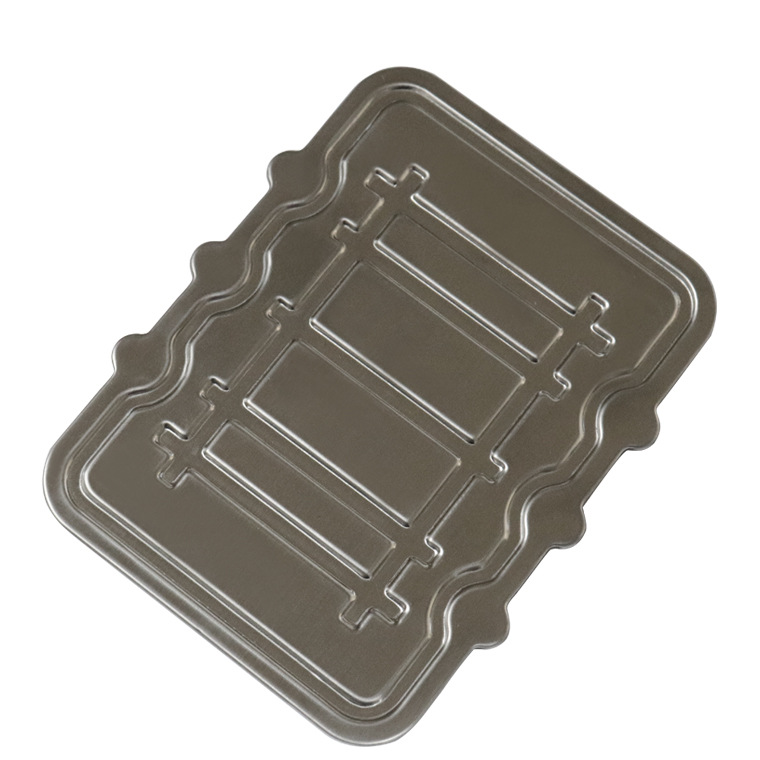

PTJ Shop is ISO 9001:2008 certified custom manufacturer of progressive die stampings for small electronic parts featuring high speed, high precision, custom metal stampings for a wide range of applications and a variety of stamping products. Serves the automotive, energy, medical, commercial, industrial, defense, and solar industries.Featuring a wide range of sizes, shapes and complexities of stamping.

Offers various production methods including progressive die, transfer press, forming, deep drawing, and spinning with stamping features such as coated, embossed, heat-treated, flat, and shape critical. Capable of handling 0.025 to 0.750 in. part thickness with capacities such as 150 to 1200 tons press rating, up to 168 in. press bed length, and up to +/- 0.0004 in. tolerance. Materials worked with include hot- and cold-rolled steel, HSLA, aluminum, stainless steel, Inconel®, and Kovar®.

Capable of stamping parts with 0.002 in. to 0.125 in. thickness and 18 in. x 12 in. dimensions. Available in prototype and medium- and high-volume capacity for short- and long-run production. Utilizes high-speed press with 140 strokes/minute operation. JIT delivery, four-week lead time, and Kanban systems are provided.

|

|

|

|

|

|

|

|

Contact our metal stamping part enginers today to discuss the specifics of your complex parts.

|

1.AS9100 Rev. B & ISO 9001:2015 certified Smart Factory and Stamping.

Production tooling is covered by a lifetime guarantee & is designed utilizing extensive planning, risk avoidance techniques including sensors, mistake proofing & PPAP. Other processes handled include degreasing, tumble deburring, reel to reel packaging as well as outside processes such as plating (stripe, spot, rack & barrel) in all common types.

2.Reliable stamping die quality assurance.

Manufacturer of progressive die systems for embossing, notching, stamping & punching applications. Features include template-positioned tooling, off-the-press setup & made from mild steel ranging from 0.25 in. to 0.5 in. thickness. Die systems are available with hole sizes ranging from 0.5 in. to 4 in. for standard systems & from 0.75 in. to 2.25 in. for heavy duty systems. Die system consist of master die set, template sets, punch holders, die holders, punches & die bushings, setscrews, strippers & gages.

3.Sheet Metal Stamping Parts Suppliers.

PTJ owned and managed factory in China for precision sheet metal manufacturing. Serviced with Sheet Parts,enclosure,fabrication,fabricator,stamping,forming,cabinet.

|

|

|

|

|

|

High Accuracy

|

Quick Quote& Service

|

Fast Delivery

|

Custom Finishes

|

Precision Machines

|

Addition Services

|

|

Contact our Stamping Shop to discuss your custom part needs today.

|

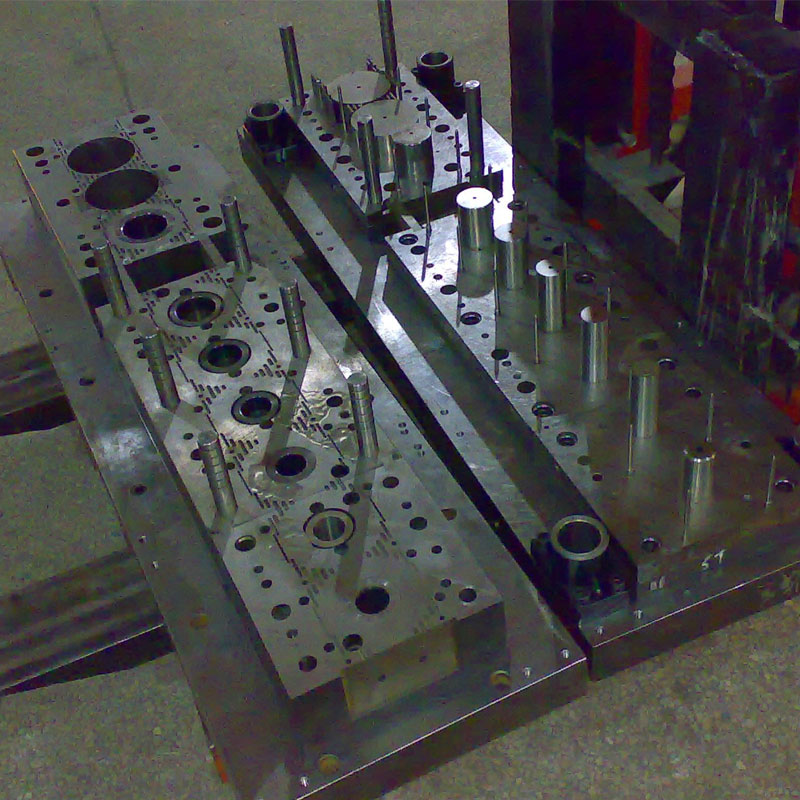

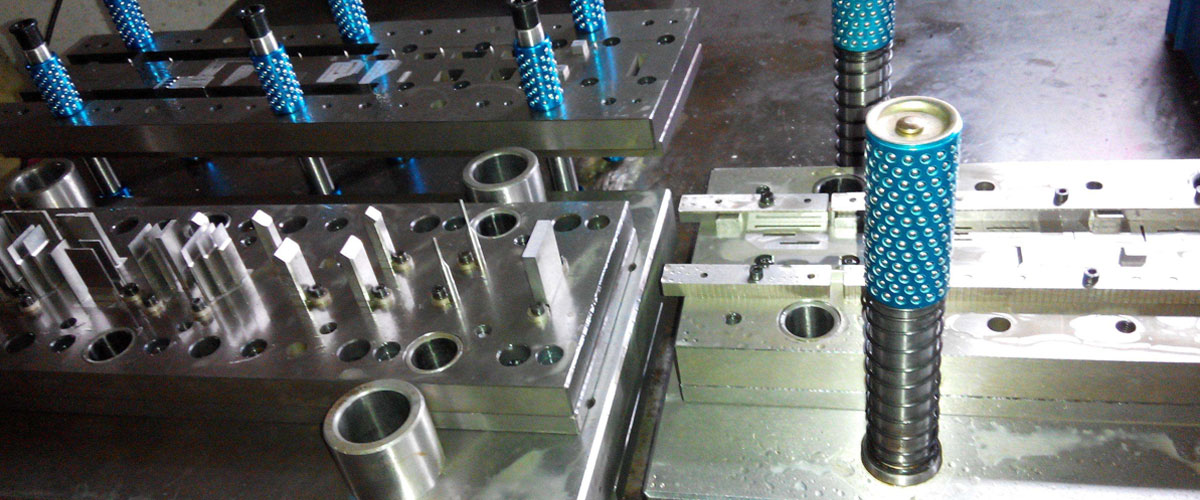

Stamping Parts and Die Machining Capabilities

Custom manufacturer of metal stamping dies. Types include progressive, pancake, transfer, side cam and compound dies. Capable of designing and building complex progressive dies up to 168 in. length. VISI-Design, SolidWorks® and AutoCAD files accepted.

Production Method:

-

▶ Punch Press

-

▶ Turret Press

-

▶ Press Brake

-

▶ Drawing

-

▶ Flat Blanking

-

▶ Medium Run Stampings

-

▶ Metal Forming

-

▶ Short Run Stampings

-

▶ An Esprit CAD/CAM system to precisely produce the most elaborate geometries (complete equipment list)

View more machining technology on our Gallery Page

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s view the other machining technology and learn more calture about PTJ Hardware.