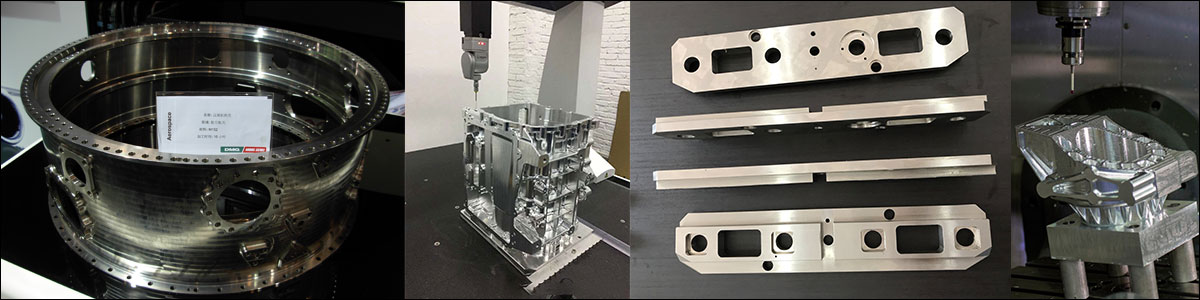

PRECISION SS 440 MACHINED PARTS

non-standard Stainless steel 440 parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from 440 Stainless Steel. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. The chemical composition of martensitic stainless steel is characterized by the addition of elements such as molybdenum, tungsten, vanadium, and niobium based on a combination of different components of 0.1%-1.0% C and 12%-27% Cr. Since the tissue structure is a body-centered cubic structure, the strength drops sharply at high temperatures. Below 600 ° C, the high temperature strength is the highest among all types of stainless steel, and the creep strength is also the highest. 440A has excellent quenching and hardening properties and high hardness. It has higher toughness than 440B steel and 440C steel. 440B is used for cutting tools, measuring tools, bearings and valves. It has higher hardness than 440A steel and higher toughness than 440C steel. The 440C has the highest hardness of all stainless steel and heat-resistant steel and is used for nozzles and bearings. 440F is a steel grade that improves the easy-cut properties of 440C steel for automatic lathes. 440 has a machining cost factor of 6.3 when compared to steel 12L14. It is not ideal for welding or forming. 440 can be forged, heat treated, and annealed. |

|

|

|

|

|

|

|

|

|

Contact our SS 440 Machining services machinists today to discuss the specifics of your complex parts. |

Stainless steel 440 Machining Industries & Applications

- ▶ Pins

- ▶ Surgical and dental parts

-

▶ Bearings

- ▶ Valve components

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;