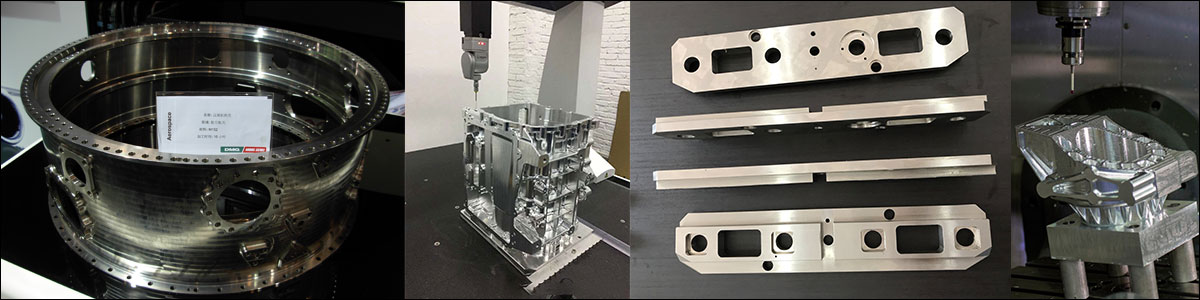

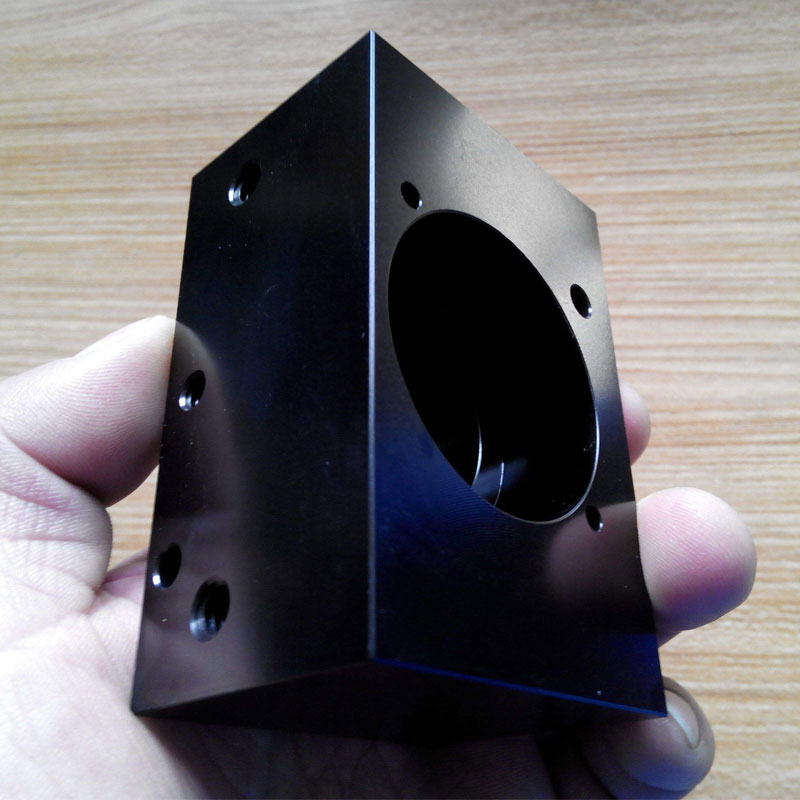

PRECISION SS 430 FR MACHINED PARTS

non-standard Stainless steel 430 fr parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from 43FR Stainless Steel. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. SUS430, Japan SUS series stainless steel. The steel grade corresponding to the SUS430 (F/FR) stainless steel and the national standard is 1Cr17. The tensile strength is greater than 450, the yield strength is greater than 205, and the HBS is less than 183 (data is annealed). Often used as architectural decoration, heavy oil burner parts, etc. 430LX adds Ti or Nb to 430 steel, lowers C content, and improves processability and weldability. Used in hot water tanks, hot water systems, sanitary appliances, household durable appliances, bicycle flywheels, etc. 430 stainless steel, steel +12% chromium can prevent the oxidation caused by natural factors, called stainless steel, codenamed 430 in JIS, so it is also called 430 stainless steel. However, 430 stainless steel is not resistant to oxidation caused by chemicals in the air. Because of the increasing amount of acidic chemicals in the air, 430 stainless steel is often oxidized (rusted) due to unnatural factors after a period of use. Happening. 430FR has a machining cost factor of 2.7 when compared to steel 12L14. It is not ideal for welding due to its high sulfur content, and does not respond to heat treatment. 430FR withstands moderate cold work and can be forged and annealed. |

|

|

|

|

|

|

|

|

|

Contact our SS 430 FR Machining services machinists today to discuss the specifics of your complex parts. |

Stainless steel 430 fr Machining Industries & Applications

- ▶ Solenoid valves

- ▶ Injectors

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;