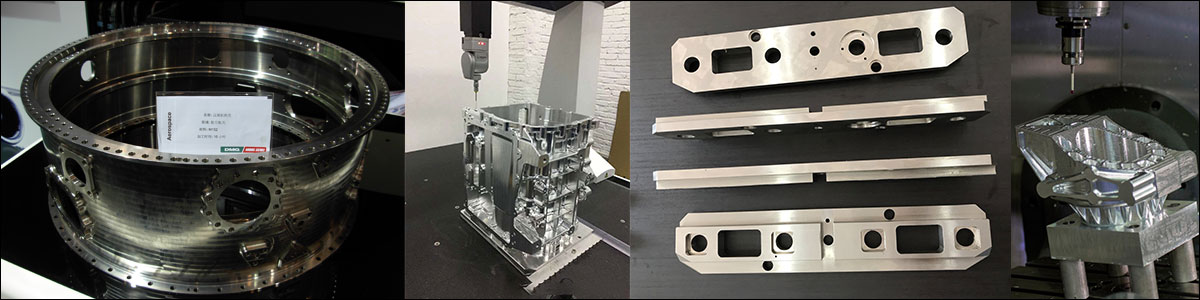

PRECISION SS 316 MACHINED PARTS

non-standard Stainless steel 316 parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from 316 Stainless Steel. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. 316 stainless steel, 18Cr-12Ni-2.5Mo Because of the addition of Mo, it has excellent corrosion resistance, atmospheric corrosion resistance and high temperature strength, and can be used under harsh conditions; excellent work hardening (non-magnetic). Equipment for the use of equipment, chemicals, dyes, paper, oxalic acid, fertilizers, etc. in seawater; photo, food industry, coastal facilities, ropes, CD rods, bolts, nuts. 316 stainless steel chemical composition: C ≤ 0.08, Si ≤ 1.00, Mn ≤ 2.00, P ≤ 0.035, S ≤ 0.03, Ni: 10.0-14.0, Cr: 16.0-18.5, Mo: 2.0-3.0. 316 stainless steel mechanical properties, tensile Strength (Mpa) 620 MIN, yield strength (Mpa) 310 MIN, elongation (%) 30 MIN, area reduction (%) 40 MIN, 316 stainless steel density 8.03 g/cm3, austenitic stainless steel generally uses this value . 316 has a machining cost factor of 5.6 when compared to steel 12L14. It is recommended for welding and hot forming capabilities are fair. 316 can be readily cold worked, but annealing afterwards is recommended to remove stresses. |

|

|

|

|

|

|

|

|

|

Contact our SS 316 Machining services machinists today to discuss the specifics of your complex parts. |

Stainless Steel 316 Machining Industries & Applications

- ▶ Bolts and nuts

- ▶ Laboratory equipment

-

▶ Valve components

-

▶ Marine equipment

-

▶ Instrumentation

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;