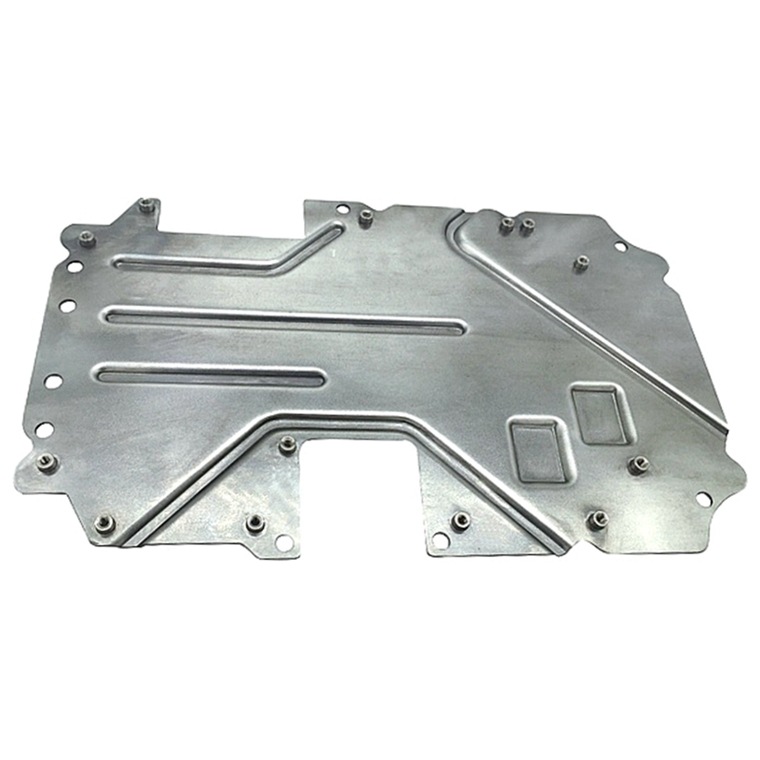

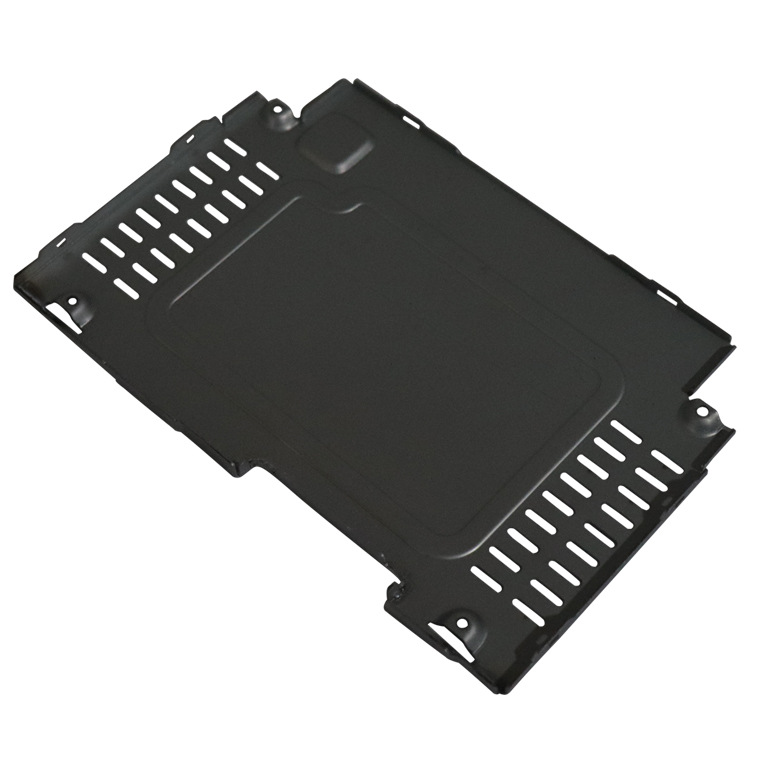

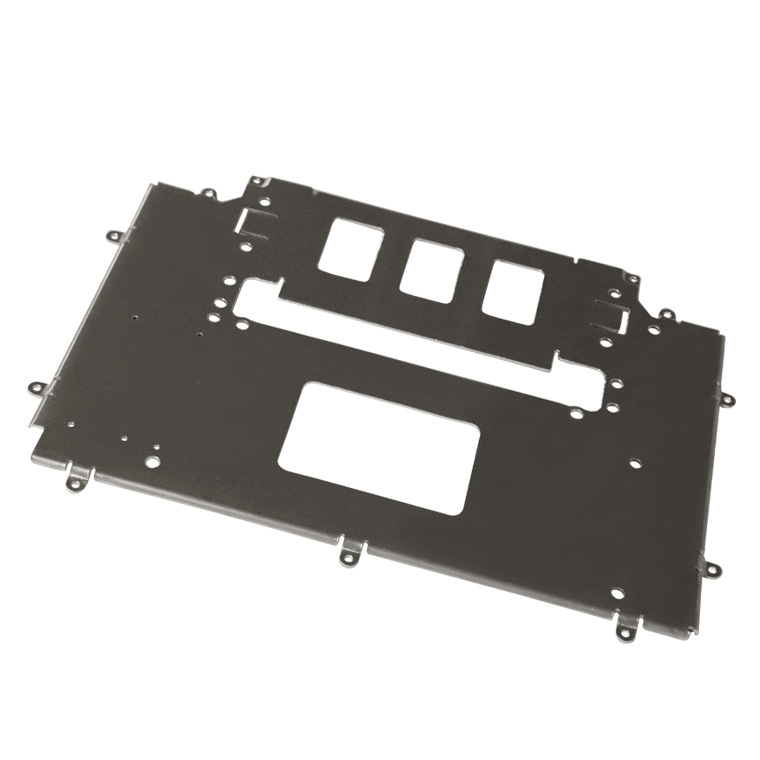

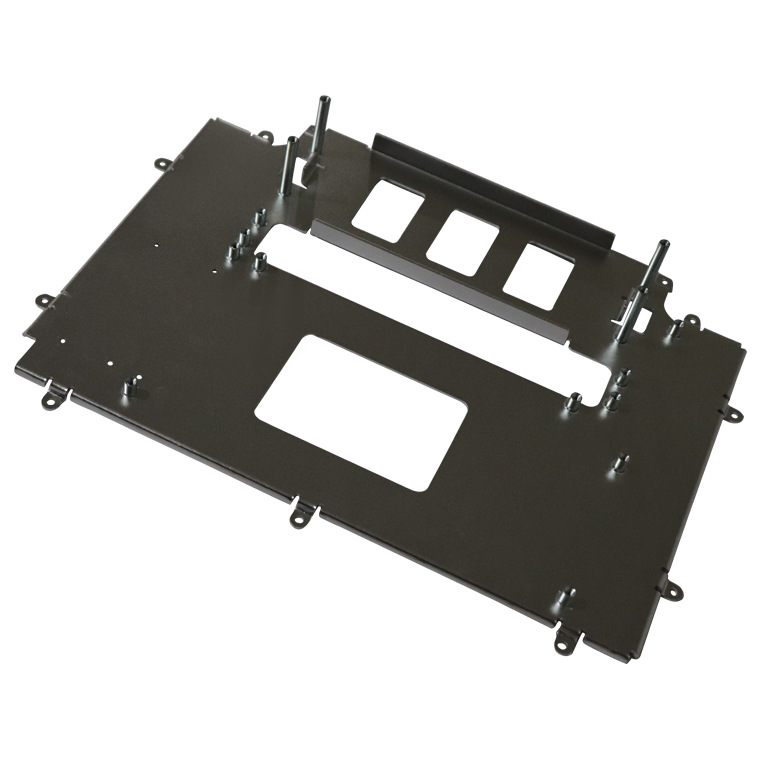

CHINA SHEET METAL SERVICES FOR NON-STANDARD CUSTOM INDUSTRY

Serviced with Sheet Parts,enclosure,fabrication,fabricator,stamping,forming,cabinet.

|

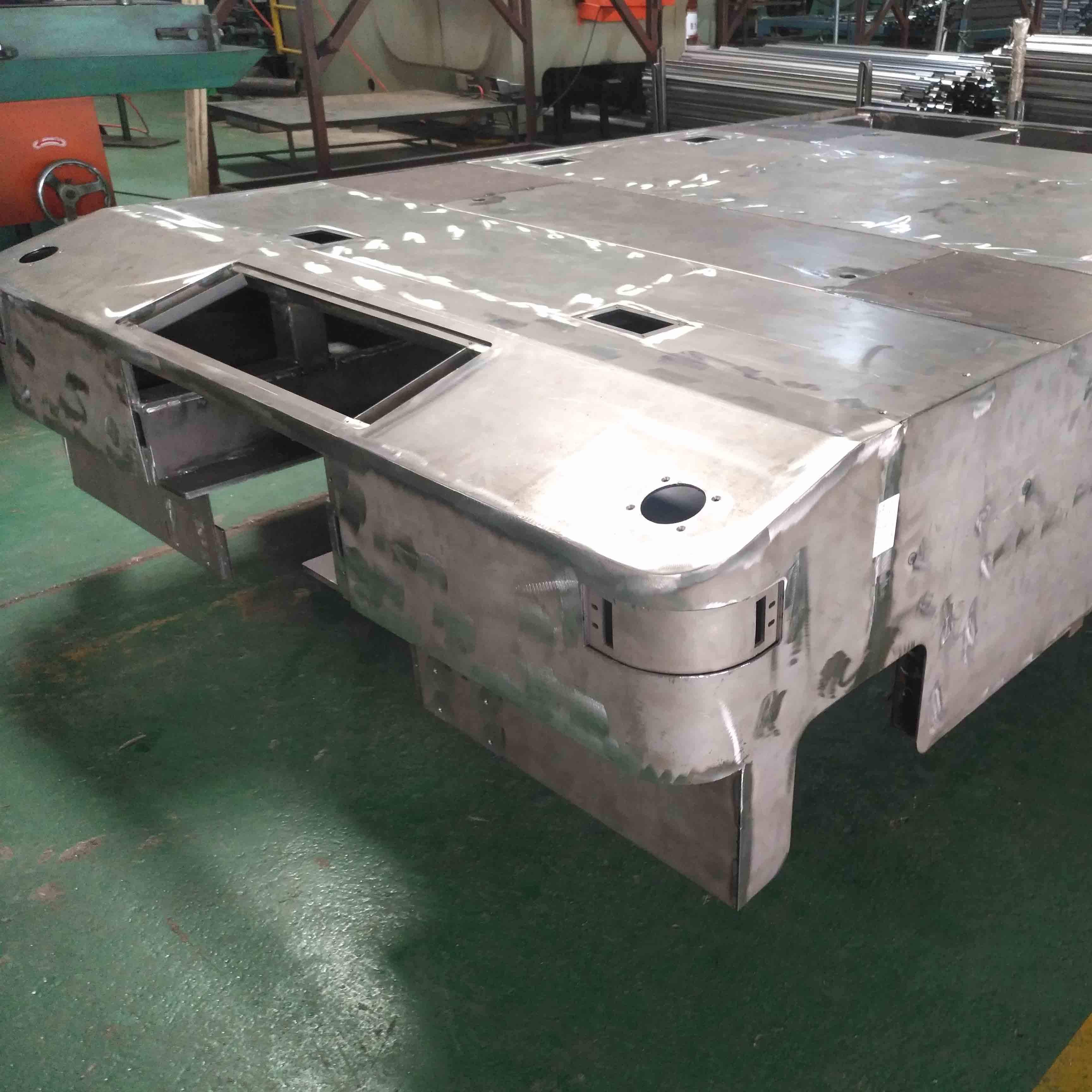

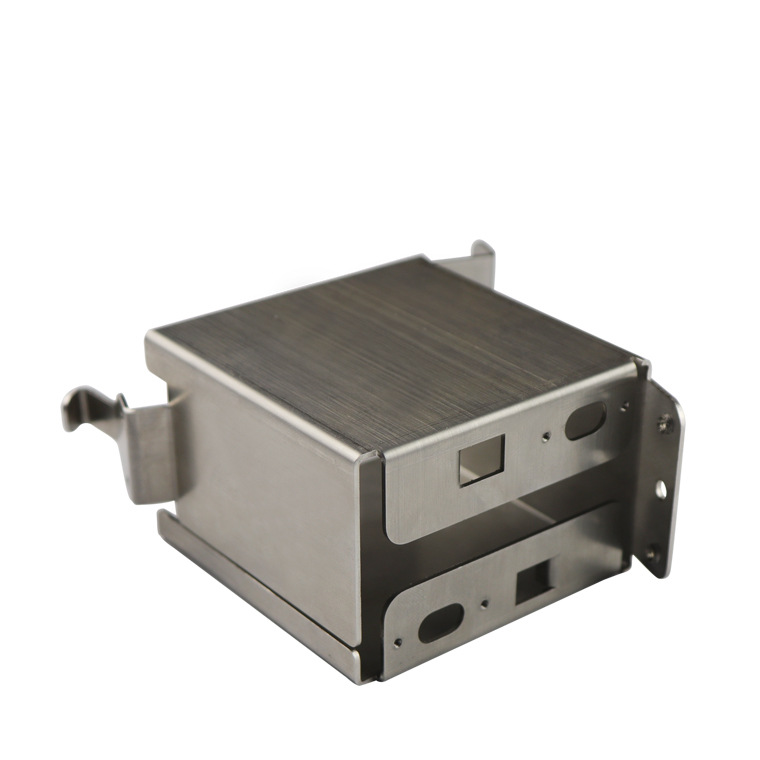

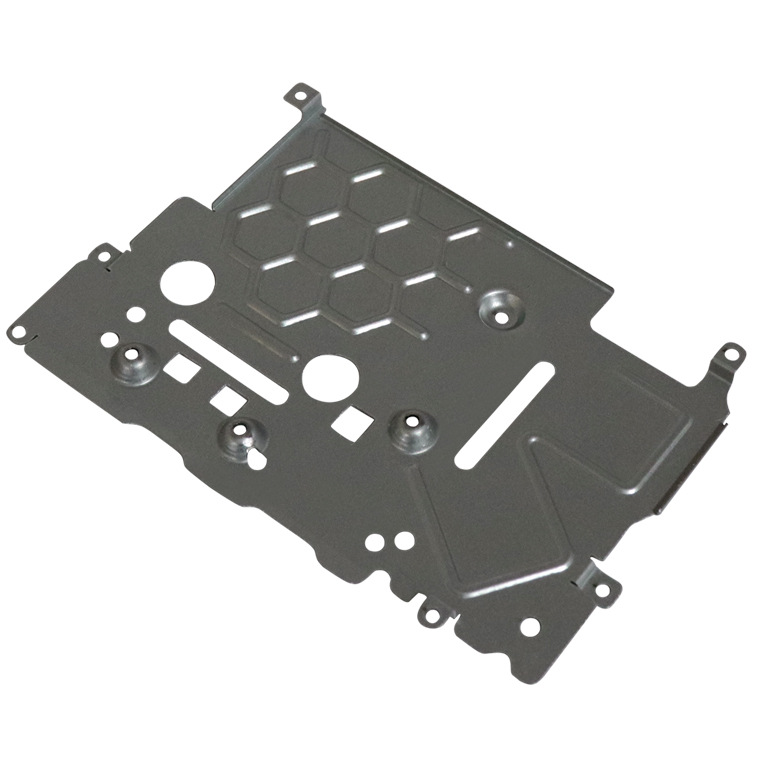

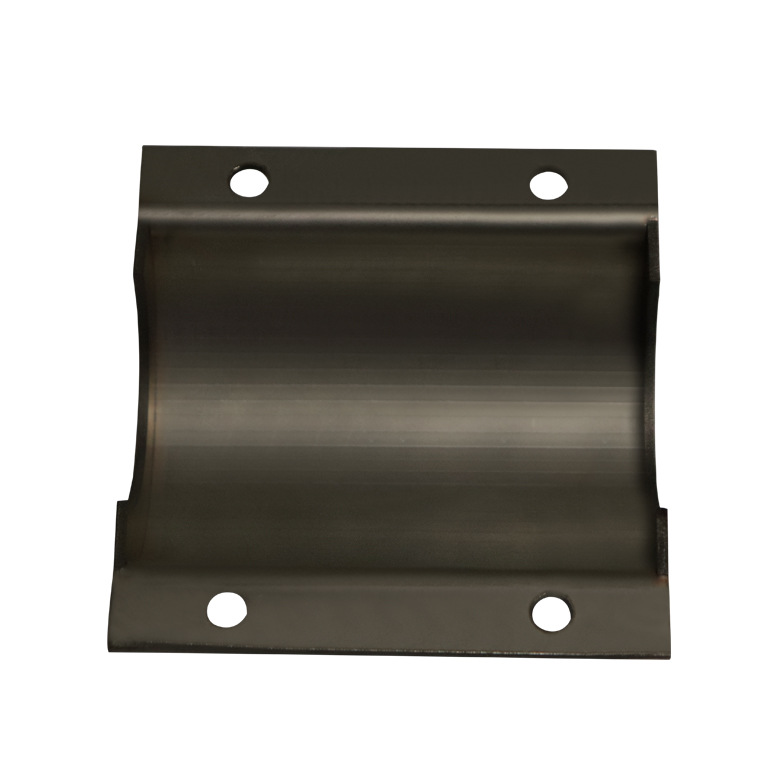

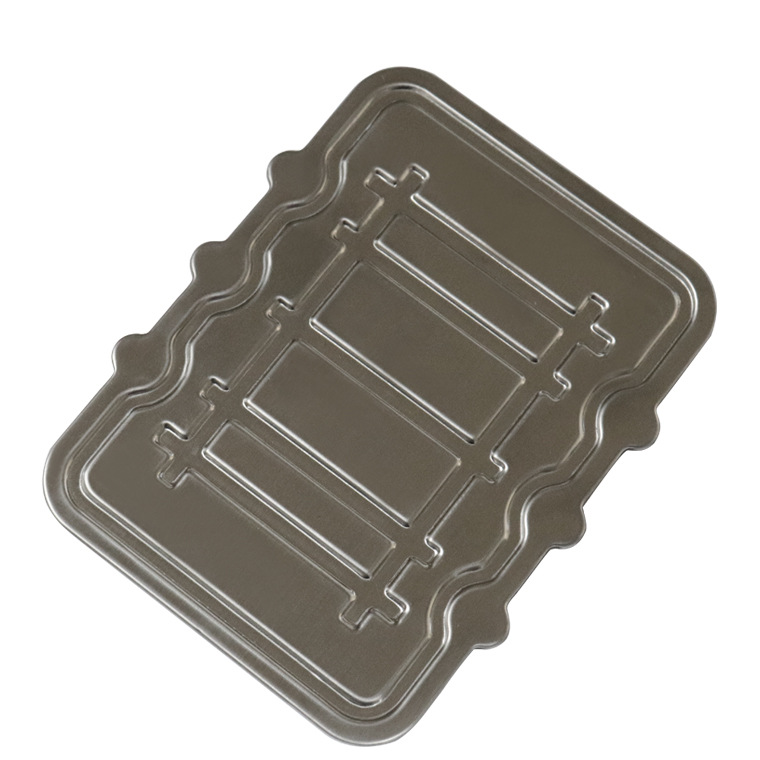

Sheet metal machining, the use of sheet metal to make chimneys, iron drums, oil tanks, air ducts, elbows, round heads, round spaces, funnels, etc. The main processes are shearing, bending, bending, bending, welding, riveting, etc. Certain geometric knowledge. Sheet metal parts are thin-plate hardware, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is a part with constant thickness during processing. Corresponding to the castings, forgings, machined parts, etc. PTJ Shop has a reputation for machining quality parts from sheet metal. We can machine intricate parts on our large laser cutter and CNC turning centers. Sheet metal machining of steel, stainless steel, aluminum, brass, copper, bronze and titanium components and parts. Capable of machining parts up to 36 ft. length and 20 in. width with +/-0.005 in. tolerance. Thickness ranges from 0.005 in. to 0.188 in. and press capacity from 5 tons to 100 tons. Roll formed products include channels, tubing, angles, bars and rings. Pre-galvanized, pre-painted, pre-anodized and pre-plated finishes available. Low tolerance miniature parts are also produced. Capabilities include insertion, swedging, punching, deburring, slotting, grooving and ring bending. Flat and shaped wire forming techniques offered such as straightening, skiving and edge rolling. |

|

|

|

|

|

|

|

|

|

Contact our sheet metal part enginers today to discuss the specifics of your complex parts. |

1.AS9100 Rev. B & ISO 9001:2015 certified Smart Factory and Lean Manufacturing.

PTJ Shop has the capabilities to manufacture parts using steel, aluminum and stainless steel.It helps you fine tune your product design through DFM and ensures that your parts can be manufactured accurately, efficiently, and at a quality that matches your specifications.2.Efficient Execution System and State-of-the-Art IT System.

Our ERP enables us to manage in-house manufacturing of finished products with multiple SKUs. Our most complex product manufactured to date is made of 320 components. With a vertically integrated factory, we are able to offer short manufacturing lead time for the manufacturing of both new and existing products.3.Strong Network of Partners and Suppliers.

PTJ Shop has the capabilities to manufacture complex, high precision parts.PTJ Shop has the best welding equipment for TIG and MIG. Our five assembly lines are capable of supporting secondary and finishing processes such as welding, riveting, powder coating, anodizing, and assembly. We are also able to provide sub-assembly service or deliver finished products. Our engineers are looking forward to discussing how your designs can take flight today.

|

|

|

|

|

|

|

High Accuracy |

Quick Quote& Service |

Fast Delivery |

Custom Finishes |

Precision Machines |

Addition Services |

|

|

Contact our Sheet Metal Shop to discuss your custom part needs today. |

Sheet-Metal Machining Capabilities

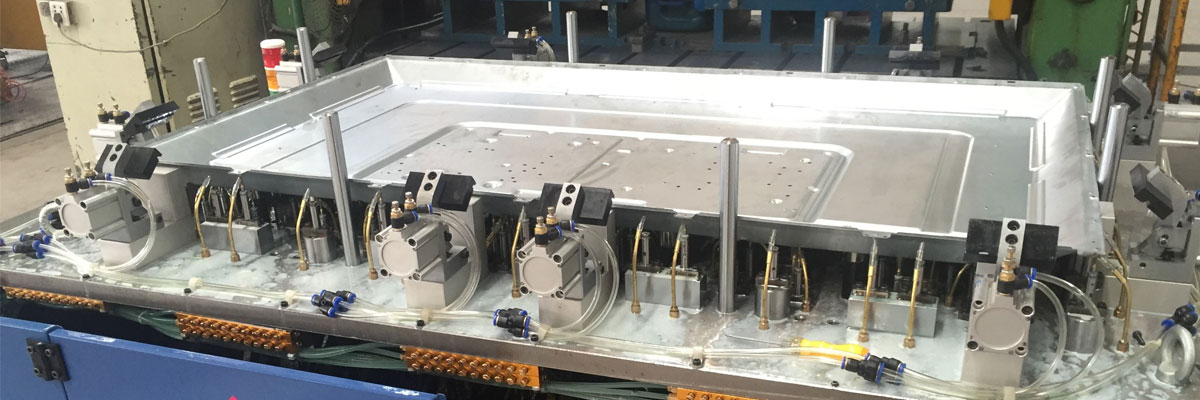

Capable of machining parts up to 36 ft. length and 20 in. width with +/-0.005 in. tolerance. Thickness ranges from 0.005 in. to 0.188 in. and press capacity from 5 tons to 100 tons. Roll formed products include channels, tubing, angles, bars and rings. Pre-galvanized, pre-painted, pre-anodized and pre-plated finishes available. Low tolerance miniature parts are also produced. Capabilities include insertion, swedging, punching, deburring, slotting, grooving and ring bending. Flat and shaped wire forming techniques offered such as straightening, skiving and edge rolling.-

▶ Exceptionally precise sheet metal machining

- ▶ Laser Cutting CO2 and N2

-

▶ CNC Sheet Bending 4 & 6 Axis

- ▶ TIG,MIG,Stamping

- ▶ Robot Welding (ABB Robot 1410 with Fronius Welding System)

-

▶ Custom-Made Jig

-

▶ Welding Notching

-

▶ An Esprit CAD/CAM system to precisely produce the most elaborate geometries (complete equipment list)

View more machining technology on our Gallery Page

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years. Let’s view the other machining technology and learn more calture about PTJ Hardware.

|

|

|

|

|

| View Detail >> | 1 | View Detail >> | 1 | View Detail >> |

|

|

|

|

|

|

|

|

|

|

|

| View Detail >> |

|

View Detail >> |

|

View Detail >> |