-

Ion Nitriding of H13 Steel for Aluminum Alloy Die Casting Molds

The combination of ion nitriding and H13 steel results in a material that is highly suitable for the demanding conditions of die casting molds.

2024-12-15

-

The Effect of Post-Processing on the Deformation of Generator Bracket Die Castings

This article delves into the scientific aspects of these post-processing effects, providing a comprehensive understanding supported by detailed tables and comparisons.

2024-12-29

-

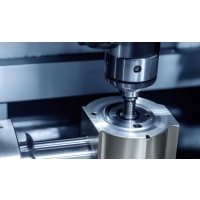

3-Axis Machining Trajectory Generation Method for Various Types of Tools on Free-Form Surfaces Based on Wireframe Models

This article delves into the intricacies of 3-axis machining trajectory generation methods for various types of tools on free-form surfaces based on wireframe models.

2024-12-23

-

4-Axis Machining Algorithm for Rotary Free-Form Surface

This article delves into the research and application of 4-axis machining algorithms, focusing on their significance, underlying principles, and practical implementations.

2024-12-16

-

Optimization Design of Free-Form Surface Ultra-Precision Turning Machining Path

This article delves into the intricacies of optimizing the machining path for free-form surfaces, covering various aspects such as tool path generation, error compensation, and surface quality assessment.

2024-12-23

-

Ultra-Precision Processing Equipment and Technology for Aspheric Curved Optical Parts

This article delves into the various ultra-precision processing equipment and technologies employed in the production of aspheric curved optical parts, providing a comprehensive overview of the methods, tools, and advancements in this field.

2024-12-23

-

Curved Cams and Five-Axis Linkage Machining Centers

This article delves into the processing of curved cams using five-axis linkage machining centers, exploring the technology, advantages, applications, and detailed comparisons with other machining methods.

2024-12-22

-

Clamping Technology of Aviation Special-Shaped Structural Parts Based on Five-Axis Machining Center

This article delves into the clamping technology of aviation special-shaped structural parts based on five-axis machining centers, exploring the intricacies, advantages, and challenges associated with this technology.

2024-12-09

-

Analysis and Research of Nonlinear Errors in Five-Axis Machining

This article delves into the analysis and research of nonlinear errors in five-axis machining, providing a comprehensive overview of the causes, effects, and mitigation strategies.

2024-12-16

-

Global Interference Collision Detection Based on Directional Bounding Box Hierarchy Tree in Five-Axis Machining of Large Propellers

This article delves into the concept of global interference collision detection based on a directional bounding box hierarchy tree, a method that enhances the efficiency and accuracy of collision detection in the machining of large propellers.

2024-12-16

-

Tool Axis Vector Optimization Method for Five-Axis CNC Machining of Complex Surfaces

Five-axis CNC machining is widely used in the production of complex geometric parts across various industries, including aerospace, automotive, medical, and mold manufacturing.

2024-12-09

-

Sharp Corner Transition Processing in CNC Machining

Sharp corner transitions in CNC machining refer to the changes in direction or sharp bends that occur when the tool path transitions from one segment to another.

2024-12-23

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material