-

The Role of Multi-Directional Forging in Improving the Performance of 7075 Aluminum Alloy

In this article, we will explore how multi-directional forging improves the performance of 7075 aluminum alloy, examining the key mechanisms through which it enhances its microstructure, mechanical properties, and overall performance in high-stress environments

2025-02-24

-

Positioning accuracy of CNC machine tools

This article will explore the different factors influencing positioning accuracy, methods of measurement, sources of error, and techniques for improving accuracy in CNC machine tools. Detailed tables will also be provided for comparison.

2025-02-17

-

The Effect of Powder Particle Size on the Preparation of Aluminum Foam by Powder Metallurgy

This article delves into the scientific understanding of how powder particle size affects the preparation of aluminum foam via powder metallurgy.

2025-02-24

-

Application of Information Management in the Powder Metallurgy Industry

This article examines the role of information management in the powder metallurgy industry, highlighting its impact on various operations such as process control, inventory management, supply chain coordination, quality assurance, and product traceability.

2025-02-24

-

The Sub-Thermal Carbonitriding Of Iron-Based Powder Metallurgy Parts

Sub-thermal carbonitriding is typically conducted in the range of 400-600°C, a temperature window that is particularly advantageous for iron-based powder metallurgy (PM) parts, as it avoids the risk of sintering and preserves the integrity of the porosity that is inherent to these materials.

2025-02-17

-

What Is Powder Metallurgy Porous Material

Powder metallurgy (PM) porous materials are a class of engineered materials characterized by their controlled porosity, achieved through the consolidation and sintering of metal powders.

2025-02-23

-

Cryogenic Treatment of Powder Metallurgy Molds

This article explores the science behind cryogenic treatment, its effects on powder metallurgy molds, material behavior, mechanical properties, experimental studies, and industrial applications. It includes detailed tables comparing treated and untreated molds across various parameters.

2025-02-24

-

CNC Precision Machining of Quadratic Curved Surface Punches

This article explores the scientific and engineering principles behind CNC machining of quadratic curved surface punches, including toolpath generation, cutting strategies, material considerations, surface finishing, and quality control.

2025-02-16

-

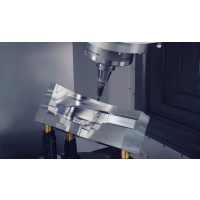

Five-Axis Machining Technology of Axial-Flow Closed Impellers

This article delves into the intricacies of five-axis machining, its application to axial-flow closed impellers, and the scientific principles that underpin this technology.

2025-02-17

-

Application of Five-Axis Linkage CNC Machining in Special-Shaped Stone Products

The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software further enhances the capabilities of five-axis CNC machining, allowing for the production of intricate and detailed stone products, including three-dimensional portraits.

2025-02-24

-

Semi-Solid Metal Processing Technology and Its Application in the Automotive Industry

This article explores the semi-solid metal processing technology, its principles, advantages, and challenges, and provides an in-depth analysis of its application within the automotive sector.

2025-01-20

-

Application of Macro Programs in Non-Circular Curve Contour Turning

This article delves into the principles, applications, and benefits of using macro programs in non-circular curve contour turning, supported by detailed tables for comparison.

2025-01-20

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

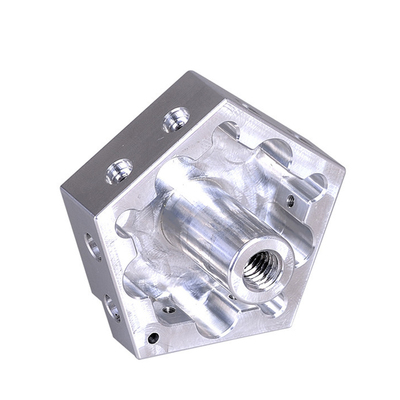

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material