-

New Technology Of Die-Casting Mold Surface Treatment

Die-casting molds are a large category of molds. With the rapid development of the world's automobile and motorcycle industry, the die-casting industry has ushered in a new era of development. At the same time, higher requirements are put forward for the comprehensive mechanical properties and life of die-casting molds.

2021-04-10

-

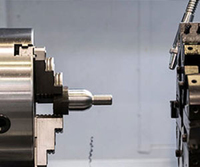

CNC Machining Technology of Sealed Pipe Taper Thread

The CNC machining technology of sealing pipe taper threads is discussed, the current standards of Chinese pipe threads are explained, the characteristics, process analysis and program design of sealing pipe taper threads are explained in detail, and the processing is combined with specific examples. The technology has been systematically analyzed in order to provide reference for the needs of relevant parties.

2020-12-10

-

The Machining Method Of Constant Velocity Plane Spiral Surface

When the contour curve of the straight forming surface on the workpiece is more complicated, it has not only straight lines and arcs, but also curves with other shapes, such as constant velocity spirals, constant acceleration and constant deceleration spirals, certain regular function curves and irregular When it is composed of non-functional curves, it can be called a complex forming surface.

2020-09-19

-

The Functions And Characteristics Of Precision Parts Machining Indexable Milling Cutters

There are many structures and varieties of indexable milling cutters, including various cemented carbide indexable face milling cutters, end mills, slot milling cutters, forming milling cutters and crankshaft milling cutters, etc.

2020-09-26

-

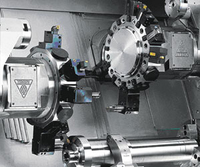

The Elements Of Affect The Turn-mill Machine Tools Machining Accuracy

For high-speed precision turning and milling machine tools, the spindle system is an electric spindle structure, and the machining accuracy of the machine tool depends to a large extent on the accuracy of the machine tool electric spindle system and is affected by the accuracy of the tool.

2020-09-19

-

The Advantages Of Turn-Mill Machining

There are two main forms of Turn-Mill machining: contour machining when the workpiece is parallel to the tool axis; surface machining when the workpiece is perpendicular to the tool axis.

2020-09-25

-

The Distinction Between Precision Bearings And Ordinary Bearings

The grades increase in sequence, with P0 being ordinary precision and other grades being precision grades. Of course, different classification standards and different types of bearings have different classification methods, but the significance is one-to-one.

2020-04-04

-

The difficulty of manufacturing high-end bearings

The bearing is an indispensable core component in mechanical equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient and ensure the rotation accuracy.

2020-04-04

-

What Is Machine Tool?

The machine tool is a machine that processes blanks or workpieces of metal or other materials to obtain the required geometry, dimensional accuracy, and surface quality.

2020-04-11

-

The Method Of Improving Lathe Machined Accuracy

CNC lathe machining is currently one of the most widely used machining forms. Compared with ordinary lathes, its machining accuracy is high, and the dimensions of the parts being processed are consistent

2020-03-07

-

Application Of CF / PEEK Materials In The Medical Device Industry

In recent years, continuous CF / PEEK composite materials have appeared frequently at medical device exhibitions, and they have also begun to show up in medical device companies. What are the unique advantages of this composite material so attractive to the medical device industry?

2020-03-14

-

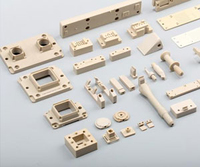

Detecting Coaxiality Method Of Machined PEEK Parts

PTJ Shop is a full-industrial chain company with both R & D, production and sales of PEEK and other plastic processing and finished parts. This article introduces our company's method for precision detection of peek parts.

2020-03-14

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material