Manufacturer Of Non-standard & Custom Pin

ISO 9001:2008 certified manufacturer of catch bolts including pintles,peg and bolt carrier

|

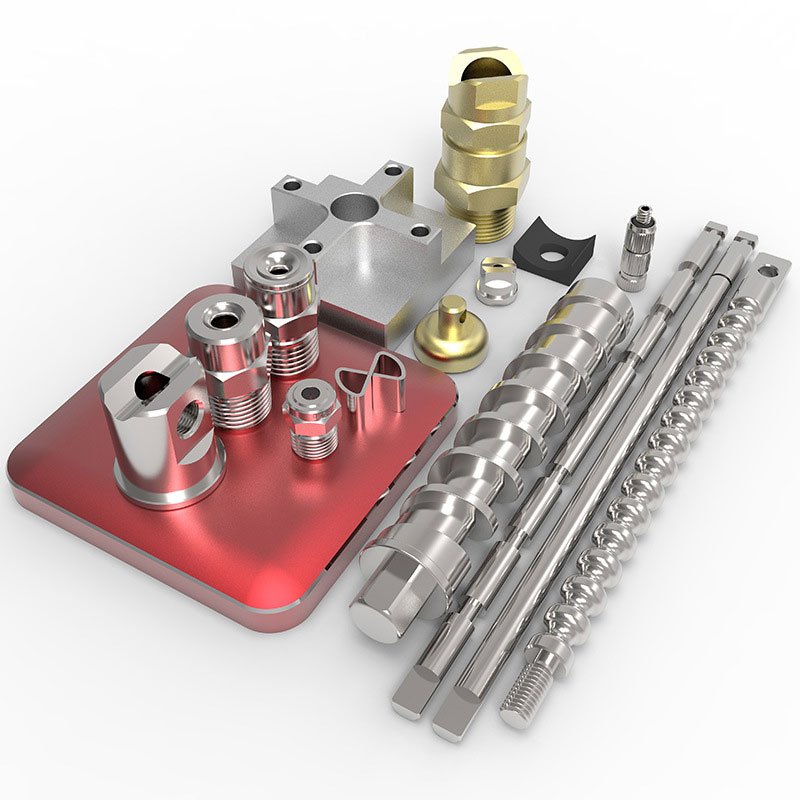

In machinery, the pin is primarily used for assembly positioning and can also be used as an overload shear connection in a connection and relaxation level safety device. The types of pins are: cylindrical pins, tapered pins, perforated pins, split pins and safety pins. PTJ Shop Non-standard Pintles Machining Range are available in different sizes, shapes, ferrous & non-ferrous materials with plain & plated finishes. Capabilities include roll threading, cut threading, grooving, knurling, drilling, bending, pointing, tapping & coining. Products are made in the China. Specifications include 4.1 mm fixing hole dia., 100 mm L x 45.2 mm W x 18 mm H to 162.8 mm L x 114.3 mm W x 18.8 mm H dimensions & 100 kg to 900 kg tensile strength. Bolts are made from mild steel & stainless steel with barrel polished & zinc plated yellow color passivated finishes. |

|

|

|

|

|

|

|

|

|

View PTJ Shop Pin CNC Machining Case studies,Contact our custom services machinists today to discuss the specifics of your complex parts. |

|

|

|

|

|

|

|

|

|

|

|

|

Pin Machining Advantage

- ▶ Large Pin Manufacturing

-

▶ Custom CNC Machining

- ▶ Distributor of hinge parts including pintles

- ▶ Engineering, Reverse Engineering, Design, and FEA

- ▶ Pin Inspections and Material & Failure Analysis

-

▶ On Site Assistance & Troubleshooting

-

▶ Pin Audits, Installation & Alignment and more...

View more machining parts on our Gallery Page

At PTJ Shop, our experience and specialized knowledge in precision CNC machining results in carefully milled parts. An oil field industry customer recently contracted us to machine pin lugs which are used to mount thick gauge pipe to an assembly for an oil drilling machine. Our contour milling capability utilized for machining the pin lugs from 1018 cold rolled steel. The part shown here features dimensions of 4.00" x 3.50" x 3.00", all to tolerances of ±0.005". Dimensions, quality, and repeatability are verified through rigorous dimensional and final inspections We produced a volume of 10-100 parts per month and delivered parts from our inventory stock to our customer between two and four days. Our 'stock and release as needed' practice shortens the lead time from weeks to a few days.- ▶ PTJ's Advanced Technology Replacement Components do last longer and pass the true test - "The Test of Time"

- ▶ Heat Treating; Carburized, & Induction Hardened

TESTIMONIALS

——————

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s watch the videos and learn more calture about PTJ Hardware.

● Cnc Machining Aircraft Parts

● Cnc Machining Electronic Parts

● Cnc Machining Medical Parts

● Cnc Machining Led Housing & Heatsink

● Learn more detail for Machining Field