-

How to prevent defects in the welding process?

With the development of science and technology, more and more new welding technologies, welding equipment and advanced welding processes are continuously invented and used by people. Welding technology has become petroleum, chemical, electric power, metallurgy, transportation, electronics, national defense, and civilian use.

2021-10-25

-

5 methods of measuring the hardness of materials and their technical differences

The hardness of a material is defined as the resistance of a particular material to local plastic deformation or indentation. The term can also be used to describe the resistance of a material to scratching, abrasion, or cutting. As far as metals are concerned, hardness is most often used to assess their ability to resist permanent deformation caused by concentrated application of loads.

2021-10-25

-

Surface Treatment Before Oxidation

The influence of the material composition and purity of aluminum products on the quality of the aluminum oxide oxide film has long been understood by science and technology workers.

2020-01-04

-

The Relationship Between Machine Bearing Oil Gap And Working Environment

Spindle bearing oil is a special lubricating oil for the spindle bearings of precision machine tools and similar equipment. It plays a very important role in ensuring the working accuracy and performance of the spindle and prolonging its service life.

2021-10-16

-

Preparation Principle Of Anodized Aluminum

Regarding anodization, the following will specifically explain the aspect of anodized aluminum, because it is in the knowledge system of anodization, so it cannot be omitted, and it needs a comprehensive and profound understanding.

2019-12-14

-

Difference Between Anode And Chemical Oxidation

Anodization, the knowledge and understanding of it, will continue to proceed because it is one of the website products, so it must be carried out, and it must not be sloppy and lax.

2019-12-14

-

Method For Avoiding Gap Of Anodized Aluminum Alloy Due To Oxidation

With the rapid development of technology, the development of the foundry industry has become faster and faster, and anodized aluminum alloys have also been fully utilized.

2019-12-21

-

Aluminum Anodizing Sealing Process

The aluminum oxide film is a porous film. Regardless of whether it is colored or not, it must be sealed before being put into use, so as to improve its corrosion resistance and weather resistance.

2019-12-21

-

The Difference Between Anodizing And Conductive Oxidation

In order to overcome the defects of aluminum alloy surface hardness, wear resistance, etc., expand the scope of application and extend the service life, surface treatment technology has become an indispensable part in the use of aluminum alloys, and anodizing technology is currently the most widely used and most successful of.

2019-12-14

-

Three Factors Affecting SCC Stress Corrosion Of Aluminum Plates

The chemical source of SCC is chloride. Chloride ion chemically interacts with the material at the crack tip. Since the tensile stress at the crack tip is the largest, it makes it easier for the crack to spread around.

2019-12-14

-

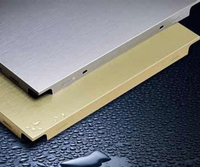

Ideal Material Choice For Hard Anodizing

In the hard anodizing process, insoluble elements: silicon, lead; elements that are dissolved but exist as oxides or other insoluble compounds: magnesium, zinc;

2019-12-21

-

Relative Comparison Of Anodizing And Hard Oxidation

Aluminum alloy and hard film Anodized film is obtained from aluminum material as anode. Aluminum alloy material has a great influence on the performance of film.

2019-12-21

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material