-

Judge The Quality Of Laser Cutting From Several Sheet Metal Latitudes

In the process of sheet metal processing, there are many times when we don't know how to judge the quality of sheet metal processing. Today, the editor will explain to you how to judge the quality of sheet metal laser processing from several latitudes and evaluate its processing quality.

2021-04-08

-

Analysis of Cnc Precision Carving Process

CNC precision engraving machine is a kind of CNC machine tools. Metal engraving machine can perform non-contact cutting and punching on metal or non-metallic plates and pipes, especially suitable for laser cutting of stainless steel plates, iron plates, silicon wafers, ceramics, titanium alloys, epoxy, A3 steel, diamond and other materials .

2020-02-15

-

How To Solve Common Problems In Polishing ?

When designing, mapping, or drawing a machine or component, you must draw a part drawing. The accuracy of the parts drawing directly affects the performance of the machine or component. So for the designer who draws the drawing of machining parts, the requirements are very high. This article will introduce the drawing method of machining parts in detail

2020-01-11

-

The Essential Difference Between PLC And SCM Control System

In this way, PLC is not mysterious. Many PLCs are very simple. In addition to the high speed of the internal CPU, other functions are not as good as ordinary single-chip microcomputers. Usually PLC uses 16-bit or 32-bit CPU, with 1 or 2 serial channels to communicate with the outside world, and there is a timer inside. If you want to improve the reliability, add a watchdog timer to solve the problem.

2021-10-23

-

3D printing plays an indispensable role in industrial manufacturing

3D printing will soon become a game changer in manufacturing. Blake Teipel, CEO and co-founder of Essentium, explained why.

2021-11-18

-

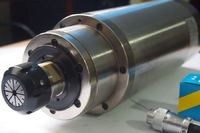

The Repair Technology Of Machining Center Electric Spindle

Electric spindle is a new technology that integrates machine tool spindle and spindle motor in the field of CNC machine tools in the past ten years. It is the "core" component of high-speed CNC machine tools, and its performance directly determines the high-speed processing performance of the machine tool.

2021-10-16

-

What are the specifications and models of the pe tube?

Plastic pipes can be divided into polyvinyl chloride (PVC) pipes, polyethylene (PE) pipes, polypropylene (PP) pipes, polybutylene (PB) pipes, ABS pipes, etc. according to their materials. Because PE pipe has the characteristics of easy construction, corrosion resistance, no pollution, long service life, etc., its development momentum is eye-catching.

2021-10-25

-

Surface Treatment Of Duplex Stainless Steel S39240

According to EN 10088-1: 2007 and EN 10088-3: 2007, stainless steel two-phase duplex stainless steel 1.4462, X2CRNIMON22-5-3 resistant to intergranular and stress corrosion, ferrite-austenite structure

2020-05-02

-

PTJ Develops New Surface Plating Process For PEEK Material

In order to meet the special needs of customers for PEEK performance, the company recently developed the PEEK surface plating process. The process can be divided into: chemical plating and electroplating. At present, the metal coatings on the PEEK surface that can be used for electroplating are: gold, silver, copper , Nickel, chromium.

2020-03-14

-

Aluminum-Parts Surface Treatment Cleaning Steps

After the oxidation of aluminum, the original physical shape cannot be restored. Because the oxidation reaction that occurs is intermolecular, the metal bond interactions between them cannot be recovered, and they can only be reduced to the furnace.

2020-01-04

-

Composition and structure of powder electrostatic spraying equipment

Powder electrostatic spraying equipment mainly includes: powder spraying room, high voltage electrostatic generator, electrostatic spray gun, powder feeder, powder recovery device, workpiece rotating mechanism, etc.

2021-10-16

-

The Selection Requirements Of Lathe Mechanical Spindle

The main shaft is the most common part of the machine. It is mainly composed of inner and outer cylindrical threaded splines and transverse holes. The main shaft is the executive part of the machine tool. It mainly supports the transmission parts and transmission torque. It drives the workpiece to directly participate in the surface forming movement, and the spindle also ensures that the workpiece has the correct relative position to other parts of the machine tool.

2021-10-16

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

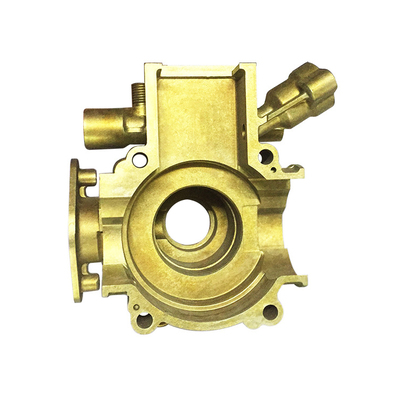

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material