-

What method should be used for welding low-alloy high-strength steel? How to choose welding rod?

Low-alloy steel is an alloy steel containing less than 5% of the total alloying elements in the steel. Its application is wider than medium alloy steel and high alloy steel.

2021-10-21

-

How to choose the right stainless steel welding consumables?

This is based on the metallographic structure of stainless steel at room temperature. When low carbon steel is heated to 1550°F, its structure changes from the ferrite phase at room temperature to the austenite phase.

2021-10-21

-

Smart Manufacturing On The Tuyere: Companies Still Need To Be Rational

Entrepreneurs are desperately chasing the outlet today. For example, the "sharing economy" that exploded some time ago. A group of entrepreneurs swarmed up, and all kinds of shared companies such as "shared bicycles", "shared cars", "shared machine tools", and "shared chargers" emerged for a while. As a result, very few survived after a round of reshuffle. Therefore, although the pigs on the tuyere can fly, when the limelight passes, the pigs all fall to death.

2021-10-09

-

How To Solve The Automobile Stamping Springback Problem

The problems that occur in the production process include springback problems, so how to effectively deal with the problems The spring problem is also an aspect to improve the overall accuracy of the car. The following will briefly analyze the types of springback problems of automobile stampings, the reasons for the springback problems and the factors that affect the springback.

2021-10-09

-

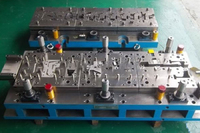

Points To Pay Attention To When Mold Parts Are Overhauled

In order to better use mold accessories, we need to conduct detailed inspection and maintenance during use. This can not only prevent mold accessories from accidents, but also extend the service life of molds, but in order to better use mold accessories, we When testing, it is best to pay attention to the following major points, which are of great help to the use of mold accessories.

2021-10-16

-

What Is High-Speed Steel Mold & Dies

The perfection and compactness of the craftsmanship creates the extraordinary use of space and market demand for the cement tooth steel mold box. It is our development direction. At present, the domestic cement tooth steel mold box production process is not perfect but we are still continuing to work hard. Realize a new era in the development of cement tooth steel mold box.

2021-10-09

-

Carbon Fiber Is Breakthrough Problem For Automobile Lightweight

If the next destination of automobile manufacturers is always faster speed, lower fuel consumption and less exhaust emissions, then lightening is a shortcut. As long as the weight of the car body is reduced, it will inevitably increase the speed, reduce energy consumption and reduce energy consumption. emission. In this shortcut, carbon fiber is an inaccessible bridge.

2021-10-02

-

The Mold Parts Need Your Careful Maintenance

For the mold structure where the discharge spring is between the fixed plate and the discharge plate and the discharge spring is directly on the inner guide column, the disassembly of the discharge plate must ensure that the discharge plate is balanced and ejected. The tilt of the discharge plate may cause the punch in the mold to break

2021-10-09

-

What Factors Are Affecting The Tensile Test Of Metal Materials

Tensile test is the most common experiment in the mechanical property test of metal materials. It is said that the tensile test reflects the basic properties of the material, but the measurement results of the same material through different tensile test processes are not necessarily the same.

2021-10-20

-

Advantages Of Finishing Agents In Additive Manufacturing: Smoothness, Compatibility, Adhesion

Initially, additive manufacturing (AM) was considered too slow or too expensive to be used in mass manufacturing. Many engineers only consider using it for part prototyping, fixture manufacturing, or low-volume operations. But recent advances in software and hardware technology mean lower costs and faster production speeds, making AM an attractive alternative, even for complex or high-volume production runs.

2021-10-02

-

The Features And Operation Of Flat Welding And Vertical Welding

Flat welding refers to the welding process in which the welding place is at a horizontal position or at a small angle of inclination, the welding rod is located on the workpiece, and the welder looks down on the workpiece. This welding position belongs to the most easily welded position among all welding positions.

2021-10-16

-

What Is Reflow Soldering?

Reflow soldering is to remelt the solder paste pre-distributed on the printed board pads to realize the mechanical and electrical connection between the solder ends or pins of the surface mount components and the printed board pads

2021-10-16

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material