-

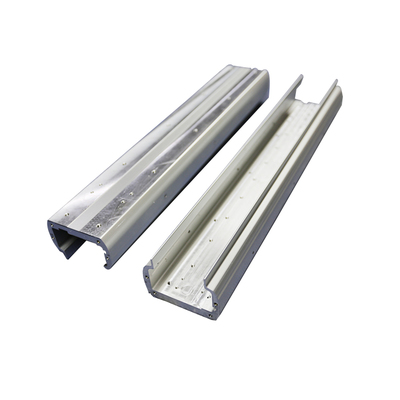

New breakthrough in nanotechnology: perfect welding of special aluminum alloys

This aluminum alloy weighs only one-third of steel, but is almost as hard as steel. Therefore, this technology can make transportation more portable and energy-saving. It is generally used in aircraft fuselages and wings. In addition, mobile phones also use this technology.

2021-10-09

-

How to determine the size reduction problem facing the processor?

Granulation, grinding, and shredding are all common terms used to describe the by-product crumbs of plastics processing. Every plastic processing equipment will produce waste and a certain degree of substandard products, and these substandard products will be discarded as waste products.

2021-10-27

-

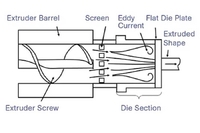

Six rules to prevent thermoplastic foam board from extruding speed collection!

Successful foam extrusion looks like art. The optimized foam process using inert gases saves materials and energy, without causing global warming or the potential for ozone depletion. Facts have proved that thermoplastic foam extrusion is beneficial to the extrusion of rigid profiles, wood and sheet materials, as well as cables, garden hoses and films. However, these six basic rules are usually ignored.

2021-10-27

-

Plastic processors should choose cooling systems in this way to improve product quality and profit margins

In an ideal world, the process cooling system can operate without any cost, and at the same time can work perfectly to keep the plastic process running smoothly and profitably. However, since there is no perfect world, the next best option is to strike an appropriate balance between planning methods and today's system technology to meet the cooling needs of operations cost-effectively.

2021-10-27

-

Five major developments in thin gauge thermoforming! Speed collection

The manufacturing tolerances of injection molded parts are very high, and thermoformed parts usually have some deviations, but recent developments have shown that thermoforming is far behind injection molding with attention to technological progress.

2021-10-27

-

What is needed to automate the horizontal injection unit to handle tiny-sized inserts and molded parts?

Insert overmolding is a strict technology in injection molding, but in the initial stage, it is not often handled by robots. It usually requires manual assistance, especially for inserts with difficult geometric shapes. The robotics and proprietary technology at that time could not handle the blade well.

2021-10-27

-

What kind of lubrication technology should be used in the new generation of large die-casting machines?

As the automotive industry struggles to cope with the ever-changing market challenges, production processes are constantly evolving, using larger and more complex die-cast parts to create lighter cars. Dr. Mark Cross, Global Business Development Director of Quaker Houghton Die Casting, discussed how innovative lubrication technology supports the introduction of the latest generation of large-scale, over 4,500-ton die-casting machines to meet these challenges.

2021-10-27

-

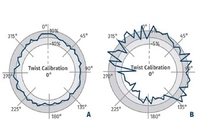

3D printing technology improves the manufacture and use of strain gauge sensors and eliminates the interference of human factors

You might think that manufacturing spirals can only be done by craftsmen with many years of experience and great attention to detail. But this is not necessarily the case.

2021-10-27

-

What should I pay attention to when spiral processing?

You might think that manufacturing spirals can only be done by craftsmen with many years of experience and great attention to detail. But this is not necessarily the case.

2021-10-27

-

What exactly is 3D printing technology?

Since 2009, the main patents for portable 3D printers have expired, and 3D printing has developed into an industry of its own. Therefore, 3D printers are one of the decisive products of our time.

2021-10-27

-

What are the common problems in the coextrusion blown film process?

The blown film industry has developed from a single-layer film structure to a multi-layer film structure for various food and non-food packaging applications. According to the requirements of the product, a variety of materials can be integrated into the film structure to obtain the required performance.

2021-10-27

-

What are the tips for cleaning the twin screw extruder?

Twin-screw extruders (TSEs) have long been the machine of choice for compounding machines due to their superior performance and customizability. They can handle almost all resins and combine different additives and fillers to achieve different particle sizes and shapes with different properties.

2021-10-27

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material