-

Troubleshoot The Sawing Problem As Follows

Through a comprehensive understanding of sawing mechanics and the specific problems that arise when sawing tubular workpieces, many problems in pipe and pipe cutting can be solved. Eliminating sawing problems helps in three areas: increasing the cutting rate, extending the life of the saw blade, and optimizing cutting quality.

2021-10-29

-

What should I do if a weld line appears during injection molding?

Welded wire or braided wire is probably the most common and difficult to eliminate injection defect. They occur when the melt flow front collides in the cavity. Poor braid will not only cause appearance defects, but also greatly weaken the structural integrity of the part. The strength of the braided wire may be only 20% of the nominal strength of the part, or it may be 100% of the nominal strength of the part, depending on many variables.

2021-10-29

-

Proper mold cleaning may be an effective way to solve burrs

The flash of a part can occur due to a variety of reasons, from process or material changes to tooling failures. Along the parting line of the mold or wherever the metal forms the boundary of the part, there will be burrs on the edge of the part. Tools are often the culprit, so identifying the type of flash being acquired and when it occurred can point you in the right direction.

2021-10-29

-

How to choose suitable surface treatment products?

Choosing the right product for grinding and surface treatment applications can be annoying, because many types of abrasive products can be used for work, and each product has many different sizes, textures, and styles.

2021-10-29

-

How to improve the return on investment of stainless steel and nickel alloy scrap?

Stamping manufacturers that produce stainless steel and high-nickel alloy scrap can easily increase the return on their material investment. By following some simple guidelines, they can get higher value from the waste.

2021-10-29

-

How does a metalworking manufacturer decide to use manufacturing or stamping technology?

The manufacturer of the metal processing workshop does not think about rejecting the customer, but before the customer makes a real request, you never know what the customer needs, you must be prepared for anything.

2021-10-29

-

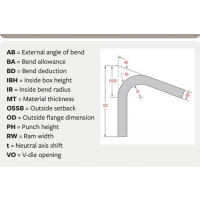

How to eliminate waste on the bending machine?

Bending is the most complicated operation in metal manufacturing, and good communication is definitely the key. In this case, as in many other cases, engineers and operators may not have as much discussion as they did before the work was officially put into production.

2021-10-29

-

Is the poor effect of the bending machine related to the material?

Despite purchasing a new bending machine, we still encountered problems, such as being unable to maintain repeated angles. Our tool is a new tool, and precision drilling really helps us shorten the installation time. But achieving a consistent angle is a headache.

2021-10-29

-

What should I pay attention to when performing the bending process on a modern bending machine?

If you walked into the bending machine department of a manufacturer 20 years ago, you would see a very different picture. A machine produces a variety of new, low-quality jobs in a shift, but it takes most of the time to set up, and in fact there is very little time to bend good parts.

2021-10-29

-

What should be paid attention to in material preparation before welding?

The welding process is a very important step in various manufacturing processes. Weld all different types of metals for many different types of manufacturing. However, in order for any welding process to be accurate and effective at the first time, the parent material must be properly prepared.

2021-10-29

-

What are the benefits of automatic deburring?

New technologies in the manufacturing industry provide metal manufacturers with more options for producing parts for their customers. In particular, fiber laser cutting machines enable manufacturers to cut more parts a day than CO2 laser cutting. The automatic loading and unloading system connected to these laser cutting machines also enables the workshop to work 24 hours a day.

2021-10-29

-

What are the ways to achieve a specific metal finish?

The surface of the part may require a specific metal surface treatment for a variety of reasons, whether it is appearance, product function, or customer preference. Certain metal finishes can also help the material resist damage or rust.

2021-10-29

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material