-

How to measure the surface roughness of large parts?

Large parts, such as the engine block of emergency generators, construction machinery or ship engines; truck steering knuckles; or gears and bearings used in wind generators are usually too large and heavy to be performed on fixed roughness measurement equipment Measurement. Nevertheless, the roughness parameters must still be tested.

2021-11-02

-

How to avoid bubbles or holes in the 3D printing manufacturing process?

Laser powder bed fusion is the dominant additive manufacturing technology and has not yet reached its potential. The problem facing the industry is that sometimes tiny bubbles or holes are formed during the printing process, and these holes form weak points in the final product.

2021-11-02

-

How to choose the best grinding process for 3D printed parts

For metal production parts manufactured by additive manufacturing (AM), post-processing is usually required, especially on functional surfaces. Abrasive machining including grinding and polishing has the ability to finish machining conventional parts and additive parts (ie, 3D printed parts).

2021-11-02

-

Cooperative team to solve machine tool supply chain problems: 3D printing may be the first choice

A cooperative team from Oak Ridge National Laboratory solved the problem of the machine tool supply chain. The first step: 3D printing the largest casting.

2021-11-02

-

The Magnesium Alloy Application In Bicycle Frame

The shock absorption effect of magnesium is 25 times that of aluminum, which makes bicycles better. It has good riding comfort; its high-temperature extrusion molding processability is good, and the thin-wall magnesium alloy pipe fittings are extruded, which significantly reduces the weight of the vehicle; the material is pollution-free, and the secondary recycling is simple. It is a green material.

2021-11-20

-

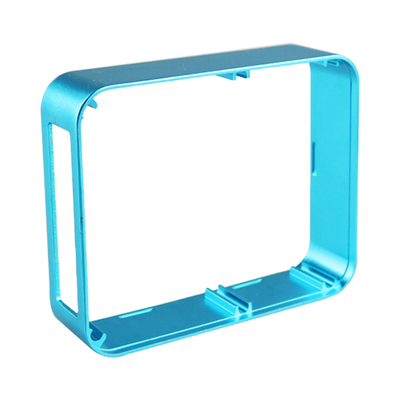

Why Is Anodic Oxidation "Favored" In Aluminum Parts Surface Treatment?

The anodizing process of aluminum and aluminum alloys has a wide range of applications in industry. It can be used to prevent corrosion of products or achieve the dual purpose of protection and decoration, such as wear-resistant layer, electrical insulation layer, spray paint bottom layer and electroplating bottom layer.

2021-10-09

-

Several 3D printing cutting-edge technology breakthroughs that shocked the world

3D printing (3DP) is a kind of rapid prototyping technology. It is a technology that uses powdered metal or plastic and other bondable materials to construct objects by printing layer by layer based on digital model files. Today, we are here to enumerate the most "tall" major advancements in the global 3D printing industry in the near future.

2021-11-20

-

The aluminum material that is touted as sweet and delicious may not be so "pure"

When it comes to aluminum, PTJ can't help but think of the motto of Lotus founder Colin Chapman. If you want to make your car faster and easier to handle, "simplify the structure, and then reduce the weight", there is no doubt that aluminum is like this. Kind of material. As an automotive machining material, aluminum alloy has good machinability, beautiful appearance, and light weight, and can play a very important role in driving control and environmental sustainability.

2021-11-13

-

The added value of the automotive bearing industry will increase by an average annual rate of 7%

The income from main business has increased by 6% annually. Among them, the average annual growth rate of high-end automotive bearing business revenue is set to 15%, and the average annual growth rate of low-end automotive bearing business revenue is set to -2%.

2021-11-13

-

Four Ways To Achieve Lightweight 3D Printing

The advantages of lightweight structure are not difficult to understand. Taking a car as an example, lighter weight can bring better handling, and the power output by the engine can produce higher acceleration. Because the vehicle is light, the acceleration performance is better when starting, and the braking distance when braking is shorter. Take airplanes as an example. If the weight becomes lighter, the fuel efficiency and load capacity can be improved.

2021-11-20

-

China's current high-end mold market satisfaction rate is less than 60%

The advantages of China's cheap labor costs and the continued and rapid development of the overall economy have brought bright development prospects to the Chinese mold industry. It is expected that by 2018, China will become one of the world's largest mold manufacturing bases.

2021-11-20

-

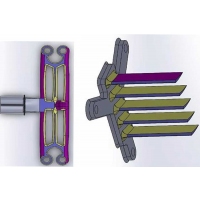

Three factors restrict the development of China's injection mold industry

In recent years, China's injection molds have developed rapidly in terms of quality and quantity. However, compared with foreign advanced technologies, the technical standards of most Chinese enterprises still need to be improved. At present, compared with foreign advanced technology, China's injection mold industry mainly has the following problems.

2021-11-06

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material