-

Introduction To The Performance Of Alumina Ceramic Materials

Among oxides with a melting point of more than 2000°C, alumina ceramics is the most flexible and cheap material. Alumina ceramics is a ceramic material with alumina (alumina) as the main body. Alumina ceramics have high mechanical strength, high hardness, low high-frequency dielectric loss, and because of its wide source of raw materials, relatively cheap prices, and mature processing technology, it is widely used in electronics, electrical appliances, machinery, textiles and Aerospace and other fields.

2021-11-06

-

Development and Application of Spray Technology in Die Casting Mould

The good spraying effect of mold lubricant is the key factor to obtain good casting surface quality. However, the existing spraying methods often fail to take into account the entire cavity surface, and there are often cases of poor spraying, local mold sticking, and strains.

2021-11-06

-

How To Choose 3D Printer?

Whether for personal, professional or educational purposes, 3D printers are more affordable than ever. Check out what you need to know about the technology to start printing, as well as the highest performing model in our official testing.

2021-11-06

-

What Are The Requirements For Spray Coating To Achieve Wear Resistance?

Under normal circumstances, the customer's requirements for wear-resistant coatings depend on the mechanical compatibility of the wear-resistant coating with the base material, the direction and size of the applied load, and the performance of the coating itself. Depending on the application of wear-resistant coatings, Xionghui Electronics' coating hardness, chemical stability, coating strength and other factors all affect the wear resistance of the coating.

2021-11-06

-

The Metal Forming Method Of Casting

The liquid metal is poured into a mold cavity suitable for the shape and size of the part, and it is cooled and solidified to obtain the production method of the blank or part, which is usually called liquid metal forming or casting.Process flow: liquid metal→filling→solidification shrinkage→casting

2021-11-06

-

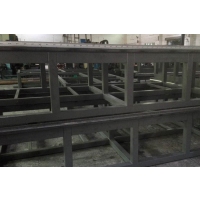

The Technical Requirements For Large Frame Welding

Large-scale frame welding machining is a common product in large-scale machining at present. When performing large-scale frame welding machining, we should not only know the machining requirements of frame welding machining, but also know the technical requirements of large-scale frame welding.

2021-11-13

-

The Common Materials Analysis Of Large-Scale Machining

In addition to knowing the common types of machining and the classification of commonly used tools for machining equipment, large-scale machining should also understand what materials are commonly used in large-scale machining.

2021-11-13

-

The Process Requirements For Shaft Machining

China’s shaft parts machining industry has developed rapidly in recent years, and various large-scale mechanical machining plants are also constantly innovating and improving shaft machining technology.

2021-11-13

-

Solutions To Common Failures In Large-Scale CNC Gantry Milling

Large-scale CNC gantry milling machining is a common machining method for large-scale hardware. When performing large-scale CNC gantry milling machining, we should not only understand the safety production precautions of large-scale CNC gantry milling operators and the equipment characteristics of large-scale CNC gantry milling machining, but also To understand the solutions to some common faults in large-scale CNC gantry milling.

2021-11-27

-

The Pre-Welding Technical Preparation For Large Frame Welding

In the welding process of large racks, we not only need to understand the technical requirements of welding machining of large racks and the machining requirements of welding machining of racks, we also need to understand the welding technical preparations for welding machining of large racks, only know the welding of large racks

2021-11-13

-

How To Choose Tooling And Fixture For Large Frame Welding

In the process of large-scale frame welding machining, we should not only know the welding technology preparation for large-scale frame welding machining and the technical requirements of large-scale frame welding machining, we should also know How to choose the tooling and fixture for welding machining of large frame.

2021-11-20

-

Machining Process Rules And Methods

The formulation of machining process regulations is an important procedure document that must be implemented for large mechanical machining plants. In the process of customizing the machining process regulations of large mechanical machining plants, in addition to formulating the selection principle of positioning benchmarks, attention should also be paid to the selection of machining methods.

2021-11-20

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material