-

Several common surface treatment methods for stainless steel processing

Sand blasting is the introduction of compressed air as the driving force to produce rapid blast sand blasting materials (copper sand, quartz sand, diamond sand, iron sand, sea sand, etc.), which are quickly sprayed to the surface of the product workpiece, and the surface of the product workpiece is changed.

2021-12-21

-

Sheet metal machining process

According to the difference in the structure of sheet metal parts, the production process can be different, but the total does not exceed the following many levels.

2021-12-21

-

The principles that CNC lathes should follow in the sequence of turning parts

After selecting the processing method and dividing the process, the next step is to arrange the sequence of the process reasonably. The processing procedures of parts usually include cutting procedures, heat treatment procedures and auxiliary procedures.

2021-12-21

-

How to set a safe tool change point for CNC machining center?

The CNC indexing head can provide a lot of convenience for some multi-faceted products. It can process the workpiece at multiple angles at one time, so it can significantly reduce the processing procedures

2021-12-21

-

Selection requirements of cutting fluid in CNC machine tool processing

With the development of industrialization, the metal processing industry is also developing rapidly, and various new materials and new process innovations are constantly emerging.

2021-12-21

-

What is the difference between machine turning and milling?

Lathe processing means that the work piece rotates, but the tool does not rotate; the milling machine processing means that the tool rotates but the work piece does not rotate. A lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece.

2021-12-21

-

Technical introduction of three-axis machining center and four-axis machining center

The most effective processing surface of the vertical three-axis machining center is only the top surface of the workpiece, and the horizontal type can only complete the four-sided processing of the workpiece with the help of the rotary table.

2021-12-21

-

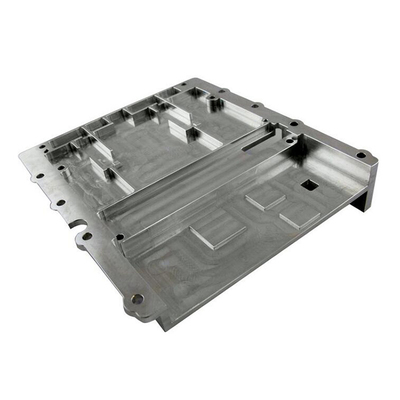

What are the advantages of cnc machining?

The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification.

2021-12-21

-

What is the main purpose of cnc machining?

CNC machining is responsible for the operation, CNC machining maintenance and daily maintenance of the machining center machine tool, and is familiar with the performance and basic structure of the machining center machine tool;

2021-12-21

-

Stability of the production of metal stamping parts and its influencing factors

What is stability? Stability is divided into process stability and production stability. Process stability refers to a stable process plan for producing qualified products; production stability refers to a stable production capacity during the production process.

2021-12-21

-

CNC lathe machining

●Host, which is the subject of CNC machine tools, including machine body, column, spindle, feed mechanism and other mechanical parts. It is a mechanical part used to complete various cutting processes.

2021-12-21

-

The status quo and existing problems of the welding industry

The production of welding consumables in my country has generally increased in step with steel, and the output has continued to increase in recent years.

2021-12-20

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material