-

Application of Magnesium Alloy Electroplating Zinc Process

Electroplating zinc on magnesium alloy can greatly improve the corrosion resistance of magnesium alloy surface, and at the same time, it has the advantages of beautiful appearance, high hardness and good wear resistance, so it has been widely used.

2021-11-10

-

New Process of Nickel Electroplating on Zinc

Galvanizing is mainly used to prevent corrosion of steel, and the quality of its protective performance is closely related to the thickness of the coating.

2021-11-09

-

Mold application nickel-tungsten alloy electroplating process

It is generally believed that the quality of the mold is closely related to the quality of the parts. Many molds (such as die-casting molds) must be electroplated on the surface to improve their corrosion resistance, wear resistance, oxidation resistance and hardness.

2021-11-09

-

Explain the two-color electroplating process in detail

In recent years, with the continuous improvement of people's living standards, a single plating color can no longer meet people's needs, and two-color machines and multi-color plating operations have emerged. It is not only beautiful in appearance but also in various forms, and has been applied to many decorations. Now I mainly share the main process flow of the two-color electroplating industry:

2021-11-09

-

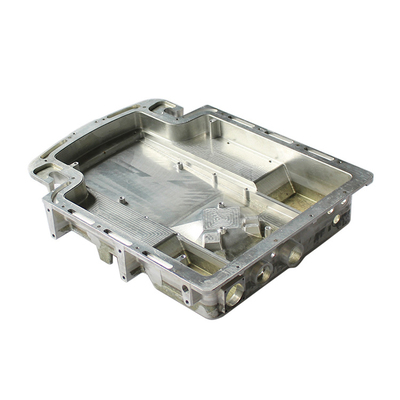

Mold plating processing

A mold is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. Known as the "Mother of Industry".

2021-11-09

-

The difference between metal plating and plastic plating

Electroplating is the process of using electrolysis to attach a metal film to the surface of metal or other materials to prevent metal oxidation (such as rust) and improve wear resistance, conductivity, light reflection, and corrosion resistance (copper sulfate, etc.) And to enhance the beauty and so on. So, do you know about metal electroplating and plastic electroplating? What is the difference between them?

2021-11-09

-

Introduction of aluminum surface treatment technology

Aluminum is usually processed into castings, forgings, foils, plates, strips, tubes, rods, profiles, etc., and then cold bending, sawing, drilling, assembling, and coloring. The main metal element is aluminum, and some alloying elements are added to improve the performance of aluminum. What is the technical process for surface treatment of aluminum?

2021-11-09

-

Failure analysis in the heating process of thermal surface treatment

Surface heat treatment is a metal heat treatment process that changes the mechanical properties of the surface layer by heating and cooling the surface of the steel part.

2021-11-09

-

Anti-rust and anti-tarnish measures for electroplating equipment

The equipment used in the electroplating process mainly includes various fixed tanks, barrel plating tanks, hangers, hanging baskets, etc. The following introduces the anti-rust and anti-tarnish measures of electroplating equipment.

2021-11-09

-

Pretreatment requirements for valve assembly

A valve is a mechanical device that controls the flow, direction, pressure, temperature, etc. of the flowing fluid medium. The valve is a basic component in the pipeline system. This article mainly introduces the specific requirements for pre-treatment of valve assembly.

2021-11-09

-

Surface treatment method of screw fastener

Screw fasteners are the most widely used mechanical basic parts and are in great demand. Surface treatment is the process of forming a covering layer on the surface of the workpiece through a certain method. Its purpose is to give the product surface a beautiful and anti-corrosion effect. The surface treatment methods carried out are attributed to the following methods:

2021-11-09

-

What are the requirements for screw fastener plating?

Electroplating is a common method of surface treatment for hardware screws and other fastener products. Under normal circumstances, the quality of electroplating is mainly measured by its corrosion resistance, followed by appearance. Corrosion resistance is to imitate the working environment of the product, set it as the test condition, and conduct a corrosion test on it. The quality of electroplating products is controlled from the following aspects:

2021-11-09

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material