-

The Characteristics Of Aluminum-Magnesium Alloy Welding

Aluminum-magnesium alloy has high mechanical properties, corrosion resistance, low temperature resistance, good plasticity, light weight and low price, so it is widely used in low temperature pipelines. Although aluminum-magnesium alloys have many of the above advantages, its weldability is more difficult to master than that of ferrous metals.

2021-11-10

-

What Are The Selection Criteria For Aluminum Pretreatment Chemicals?

The pre-treatment of aluminum usually includes the removal of surface grease and anti-corrosion treatment. However, certain standards are still required for the selection of aluminum treatment agents, so as to solve the problem that the grease on the aluminum surface cannot be removed, which seriously affects the effect of subsequent anti-corrosion treatment.

2021-11-10

-

Composition Characteristics And Welding Performance Of Duplex Stainless Steel S31803

Duplex stainless steel is generally divided into four types: Cr18 type, Cr21 type, Cr25 type and 25%-26% super duplex stainless steel. S31803 is a standard duplex stainless steel, belonging to the Cr21 type, accounting for more than 80% of the total duplex stainless steel.

2021-11-10

-

Characteristics and welding performance of aluminum alloy materials

Aluminum and aluminum alloy materials have low density, high strength, high thermal conductivity, strong corrosion resistance, and outstanding physical properties and mechanical functions, so they are widely used in the welding structure of industrial products.

2021-11-10

-

Briefly describe the different classifications and types of welded steel pipes

Welded steel pipes refer to steel pipes with seams on the surface that are welded after bending and deforming steel strips or steel plates into round or square shapes. The billet used for welded steel pipe is steel plate or strip steel. This article mainly introduces the types of welded steel pipes, let's take a look!

2021-11-10

-

Alloy element Ti and its heat treatment process

0Cr18Ni10Ti is a chromium-nickel austenitic stainless steel. This type of steel has excellent corrosion resistance and good comprehensive mechanical properties. At the same time, due to its excellent process performance and welding performance, it has been widely used in the chemical and light industry fields.

2021-11-10

-

Process flow for surface spraying of aluminum panel components

The spraying operation has high production efficiency and is suitable for manual operation and industrial automation production. It has a wide range of applications, mainly in the fields of hardware, plastics, furniture, military industry, and ships. It is the most commonly used coating method nowadays.

2021-11-10

-

How to insulate the plating rack?

The insulating treatment of the electroplating hanger can concentrate the current in the electroplating process on the parts, speed up the deposition speed, and save metal materials and power consumption at the same time.

2021-11-10

-

Characteristics of aluminum-magnesium alloy welding and common problems

Aluminum-magnesium alloy has high mechanical properties, corrosion resistance, low temperature resistance, good plasticity, light weight and low price, so it is widely used in low temperature pipelines. Although aluminum-magnesium alloys have many of the above advantages, its weldability is more difficult to master than that of ferrous metals.

2021-11-10

-

Application of bearing heat treatment technology

The quality of heat treatment is directly related to the quality of subsequent processing and ultimately affects the performance and life of parts.

2021-11-10

-

Operation requirements of aluminum alloy die casting machine

This article mainly introduces some operating requirements of aluminum alloy die casting machine, let's take a look!

2021-11-10

-

Maintenance of cooling and hydraulic system of cold chamber die casting machine

The cold chamber die casting machine is a kind of die casting equipment. The principle is to pour the molten metal liquid into the injection chamber (into the barrel) through the soup spoon, and then use the injection piston (hammer) to push the metal liquid into the mold at high speed.

2021-11-10

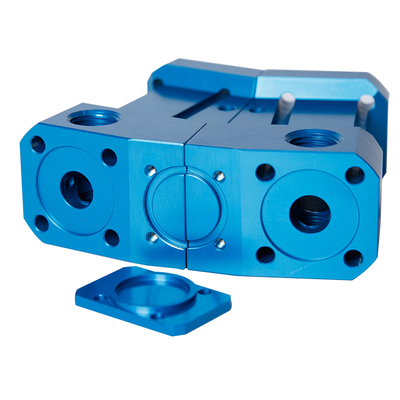

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

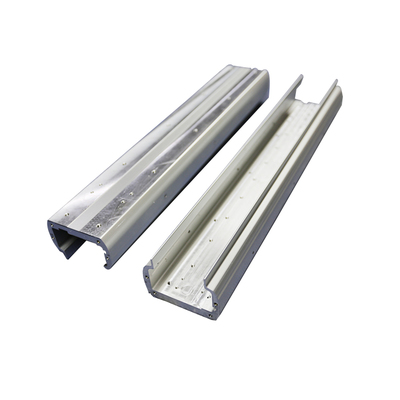

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material