-

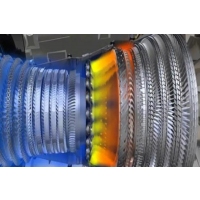

High temperature alloys are widely used

High-temperature alloy materials are widely used in many fields such as aero engines, automobile engines, gas turbines, nuclear power, petrochemicals, etc. due to their excellent oxidation resistance and thermal corrosion resistance.

2021-11-15

-

Influencing Factors and Processes of Heat Treatment Deformation of Gear Parts

Abstract: A certain analysis of various influencing factors of gear heat treatment deformation has been made. It is pointed out that the heat treatment deformation of gear parts is mainly affected by various factors such as part structure, material, forging, machining, heat treatment process and equipment.

2021-11-13

-

Talking about the New Heat Treatment Technology of Stamping Needle Roller Bearings

Since the end of the First World War, two German brothers named Schaeffler have developed the technology of punching the outer ring and cage of the bearing outer ring and cage from a thin low-carbon steel plate. The perfection and gradual improvement, thus formed the stamping needle roller bearing series, and established the INA Bearing Co., Ltd. (Schaeffler INA Bearing co.,ltd), the INA (Immer neu Aufgabe) trademark means that there are always new tasks. .

2021-11-13

-

Heat treatment technology and application of automobile bearing materials

Introduction: The automobile industry is an important pillar industry in my country, and it occupies a place that cannot be ignored in the entire processing and manufacturing industry. Bearings can be seen from multiple parts on the car body, which have the special mission of bearing load, reducing friction, and guiding moving parts.

2021-11-13

-

Analysis on the heat treatment process of aluminum and aluminum alloy

The aluminum and aluminum alloy materials are heated to a certain temperature and kept for a certain period of time to obtain the expected product structure and performance.

2021-11-13

-

Application of energy-saving heat treatment technology and equipment in the bearing industry

For small and miniature precision bearings, the chemical composition of raw materials, original organization, machining level, heat treatment process, and processing equipment may greatly affect the service life of the bearing. This article mainly talks about my personal views from the aspects of vacuum heat treatment process and equipment. Please criticize and correct any improprieties.

2021-11-13

-

Vacuum heat treatment technology for precision bearings

For small and miniature precision bearings, the chemical composition of raw materials, original organization, machining level, heat treatment process, and processing equipment may greatly affect the service life of the bearing. This article mainly talks about my personal views from the aspects of vacuum heat treatment process and equipment. Please criticize and correct any improprieties.

2021-11-13

-

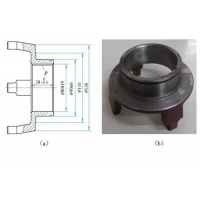

Heat treatment process of thin-walled guide sleeve

A guide sleeve is installed in the central transmission of the new full-hydraulic bulldozer produced by our company. This part cooperates with the flange plate to play a guiding and fixing role.

2021-11-12

-

Add additional functions of die-casting machine to meet the needs of die-casting process

Introduction: As the basic technical equipment of die-casting, die-casting machine has a great impact on product quality, production cost, production efficiency, etc. during the production process.

2021-11-12

-

How to improve the stability of fast injection of domestic die-casting machine

The production of die-casting parts requires die-casting machinery and equipment. Die-casting machines are the basis for the production of die-casting parts. The technical level of die-casting equipment determines the quality and level of die-casting parts.

2021-11-12

-

Common faults and solutions of low pressure casting machine

The principle of the low-pressure casting machine is mainly to fill the sealed protective furnace with a certain amount of dry compressed air. Under the action of air pressure, the metal liquid in the holding furnace will flush the mold cavity along the riser pipe to make the metal liquid in the mold cavity.

2021-11-12

-

Talking about the development and application of automobile casting process and casting technology

At present, the production technology of automobile castings in developed countries in the European and American automobile industries is advanced, with good product quality, high production efficiency and low environmental pollution.

2021-11-12

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material