-

Repair key components of power plant with 3D printing

Italian renewable energy company Enel Green Power uses 3D printing technology for its geothermal power plant to repair key parts with 3D printing. The Santa Barbara Metallurgical Laboratory in Caville, Italy, used a 3D printer to repair key components of one of its nuclear power plants and set about optimizing its geothermal power plant.

2021-11-19

-

Optimize 3D printed components for laser beam welding

For injection-molded plastic parts, laser transmission welding is already a mature industrial joining process. However, for components from 3D printers, the connection does not work because the cavities and boundary layers in the 3D printed components prevent uniform welding.

2021-11-19

-

The fundamentals of styrene copolymer (ABS) and polystyrene (PS) markets may weaken

Recently, Platts Energy Information announced that with the successive commissioning of new facilities in China, the market fundamentals of acrylonitrile-butadiene-styrene copolymer (ABS) and polystyrene (PS) may weaken in the second half of this year.

2021-11-19

-

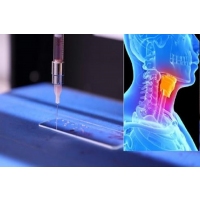

New 3D printable super soft material

A team of materials scientists at the University of Virginia School of Engineering has developed a soft material that is expected to provide a new treatment to replace severe or permanent damage to the vocal cords. Their new soft material, called elastomer, has strong stretchability, is 10,000 times softer than traditional rubber, and matches the mechanical properties of the vocal cords. Elastomers can be 3D printed for medical care.

2021-11-19

-

Customizable 3D bioprinting materials

A team of researchers from Washington State University's School of Mechanical and Materials Engineering has developed a novel, customizable 3D bioprinting material designed to better mimic the structure of natural tissues.

2021-11-18

-

Help manufacturers avoid the pitfalls of 3D printing

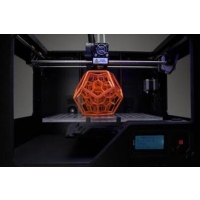

For manufacturers, 3D printing or additive manufacturing provides a way to build complex-shaped parts that are more durable, lighter and more environmentally friendly than parts made by traditional methods. The industry is booming. Some people predict that its size will double every three years, but it also has a series of problems with its rapid development.

2021-11-18

-

Break the limits of 3D printing

In a new study, researchers have shown that 3D printing can be used to manufacture high-precision and complex miniature lenses that are only a few microns in size. Microlenses can be used to correct color distortion during imaging, making it possible to use compact and lightweight cameras for various applications.

2021-11-18

-

The domestic trend of styrene fluctuates sharply

Since the beginning of this year, the domestic styrene trend has fluctuated sharply, and the overall trend has been rising. As of May 7, the price of styrene in East China closed at 10,200 yuan/ton, an increase of 64.5% during the year.

2021-11-18

-

3D bioprinting technology can control the direction of cells

3D bioprinting technology can create engineered scaffolds that mimic natural tissues. In order to regenerate applications, it is a complex and challenging process to control the tissues in these engineered scaffolds.

2021-11-18

-

3D printing technology turns algae into a flexible photosynthetic material for the first time

According to a report on the US Daily Science website on the 4th, an international research team used 3D printers and a novel bioprinting technology for the first time to print algae into a tough and elastic photosynthetic material. This material is expected to be widely used in energy, Medical and fashion fields. Related research was published in the journal "Advanced Functional Materials".

2021-11-18

-

New research on 3D printing helps development

The scientific community is intensively studying various applications of hydrogels. Hydrogels are polymer materials that contain a large amount of water and have the potential to replicate the characteristics of biological tissues.

2021-11-18

-

Laser additive manufacturing can improve the production process of 3D printed turbine blades

According to news on April 29, a team of German scientists used the FRM II neutron source to successfully analyze the residual stress of 3D printed nickel-chromium alloy specimens. In the future, it is expected to improve the production process of 3D printed turbine blades on the basis of this research.

2021-11-18

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material