-

Nanocylinder vibration helps quantify 3D printed polymer curing

Researchers from the National Institute of Standards and Technology (NIST) have taken a step towards making more precise and uniform 3D printed parts (such as personalized prosthetics and dental materials), demonstrating a way to measure the rate of microscopic areas of liquid raw materials The method will harden into strong plastic when exposed to light.

2021-11-22

-

Make electrons "pass through" the artificial crystal lattice with extremely high precision

Researchers in the Department of Physics and Astronomy have created a technique that allows them to "sketch" electronic patterns into programmable quantum materials: lanthanum aluminate/strontium titanate or "LAO/STO".

2021-11-22

-

3D printing "speed limit" can greatly improve the pass rate of products

In a project jointly developed by China and the United States, researchers discovered the "speed limit" of powder bed fusion (PBF) 3D printing, under which the possibility of defects in parts is less.

2021-11-22

-

3D printing graphene oxide method is coming

On December 14th, researchers from the Institute of Ceramics and Glass (ICV) and the Institute of Microelectronics and Nanoscience of the University of Aix-Marseille in Spain have used 3D printed graphene oxide scaffolds as the basis for lightweight hybrid structures.

2021-11-22

-

Oversupply of polyethylene is difficult to get rid of

Recently, Rob Stier, senior director of petrochemicals at S&P Global Platts Analytics, said: “As capacity returns to the market, supply will increase, and demand is unlikely in the short term. There is a strong recovery, so polyethylene prices in the global market will be under pressure in 2021.”

2021-11-22

-

Citrus peel development bio-based PEF plastic new technology comes out

The new technology developed by VTT can use pectin-containing agricultural wastes (such as citrus peel and beet pulp) as raw materials for bio-based PEF plastics to replace fossil-based PET.

2021-11-22

-

Researchers find better ways to design metal alloys

From automobiles to artificial satellites, from building materials to electronic products, high-grade metal alloys are essential in key parts of modern life. However, due to researchers' vague understanding of the boundaries between the tiny crystal grains that make up most metals, the development of new alloys with the best strength, hardness, corrosion resistance, conductivity and other properties for specific purposes is limited.

2021-11-22

-

Defect-resistant super alloy that can be 3D printed comes out

In recent years, it has been possible to use laser beams and electron beams to "print" engineering objects with complex shapes that cannot be achieved by conventional manufacturing.

2021-11-22

-

Contribute to the expansion of additive manufacturing in aerospace and other industries that rely on strong metal parts

A research team led by Tao Tao, associate professor of materials science and engineering at the University of Virginia, made two discoveries that could expand additive manufacturing in aerospace and other industries that rely on strong metal parts.

2021-11-22

-

The cause of deadly blowholes in metal 3D printing has been found!

Laser powder bed fusion (Laser powder bed fusion) is currently the most widely used metal additive manufacturing process. Under the control of computer-aided design and drawing software, it can melt metal powder through high-power density lasers.

2021-11-22

-

What are the thermophysical properties of porous Ti2AlC and Ti3SiC2 produced by powder metallurgy?

The MAX phase is a group of ternary compounds whose general formula is Mn+1AXn (where M is a transition element, a is usually from the IIIAo IVA group in the periodic table, and X can be C or N, N=1-3). They have a nano-amination structure, which gives them unusual properties

2021-11-22

-

The introduction of ultra-lightweight stainless steel is about 20% lighter than traditional stainless steel

Recently, the Korean Materials Research Institute (KIMS) Steel Materials Research Office under the Ministry of Science, Technology, Information and Communication and the Pohang Institute of Industrial Science (RIST) have developed ultra-lightweight stainless steel for the first time in the world, which is about 20% lighter than traditional stainless steel. %about.

2021-11-22

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

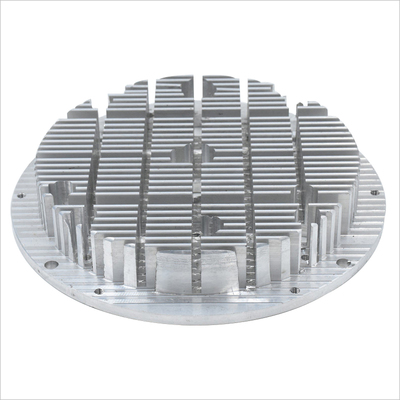

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material