-

Using gel balls as the material for stone polishing, it can be polished very well without pollution!

In order to realize the green production of sealing stones, a new type of sol-gel polishing tool composed of gel balls was developed, and its processing performance and degradability were evaluated. Through different molding and drying methods, small-sized gel balls were obtained.

2021-11-24

-

The new semi-solid casting material can be widely used in the manufacture of automobile mechanical parts!

A357 type (Al-Si-Mg) aluminum semi-solid casting material is known for its excellent strength and good ductility. It is the material of choice and is ideal in the manufacture of automotive mechanical moving parts.

2021-11-24

-

The newly launched laser cladding technology can effectively improve the wear resistance of composite coatings!

In order to improve the performance of the cladding layer, this study uses the Taguchi design to study the effects of laser power, scanning speed, gas flow and SiC powder ratio on the microhardness and wear volume of the cladding layer.

2021-11-24

-

The zinc oxide nanowires with controllable size were prepared by a combination of die casting and oxidation.

Electronic equipment has undergone a huge transformation in the past ten years, from rigid systems to flexible systems, and is currently evolving to retractable systems.

2021-11-24

-

3D printed mayenite composite scaffold

Three-dimensional (3D) printing technology has received considerable attention in the field of bone engineering because it can precisely control the manufacture of complex structures with customizable shapes, internal and external structures, mechanical strength, and biological activity.

2021-11-24

-

Metal organic frameworks may become more flexible

The application potential of metal-organic frameworks was discovered about 20 years ago, and since then, nearly 100,000 such mixed porous materials have been discovered. There is great hope in technical applications, especially flexible MOF. For example, as shock absorbers, they can respond to sudden high pressures, that is, plastic deformation, by closing pores and losing volume.

2021-11-24

-

The new CO2 laser beam cutting technology is more suitable for cutting hard or brittle materials!

Laser beam cutting is a non-contact, flexible production and high-productivity technology that can accurately analyze a wide range of sheet materials. For these and further benefits, laser processing is increasingly being adopted by industry.

2021-11-24

-

Use memory alloy as a driver to achieve precise positioning of extremely small displacements

Many shape memory alloy (SMA) linear actuator designs have been proposed to use different technologies for precise position control, such as displacement feedback, temperature feedback, force feedback, and resistance feedback. Each technology has its own advantages, as well as limitations and limitations.

2021-11-24

-

3D printing the smallest ship in the world

3D printing, which originated in the 1980s, has developed rapidly in recent years and is known as "one of the important symbols of the third industrial revolution." Earlier this month, physicists at Leiden University in the Netherlands used 3D printing to print the world’s smallest ship, which is only 30 microns in length, only 6 times larger than bacterial cells.

2021-11-23

-

New 3D metal printer comes out

On November 11, 2020, Optomec recently announced a new 3D metal printer based on Directed Energy Deposition (DED), a powder-based free-form 3D metal printing technology developed by Optomec based on the LENS trademark, and will continue Leading the market in more than 200 installations worldwide.

2021-11-23

-

3D printed weather station: get the most science with the least money

The researchers found that an inexpensive monitoring system consisting of 3D printed parts and low-cost sensors may not be as durable as a commercial monitoring system, but it can be as accurate as a commercial monitoring system.

2021-11-23

-

The use of 3D printing technology to develop a thin-plate electromechanical atomizer

Microfluidic structures and devices have been studied for decades, used to transport liquids through internal channels, using a variety of microfabrication solutions, such as surface and batch micromachining techniques.

2021-11-23

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

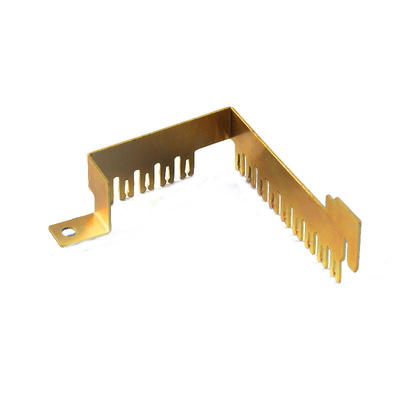

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material