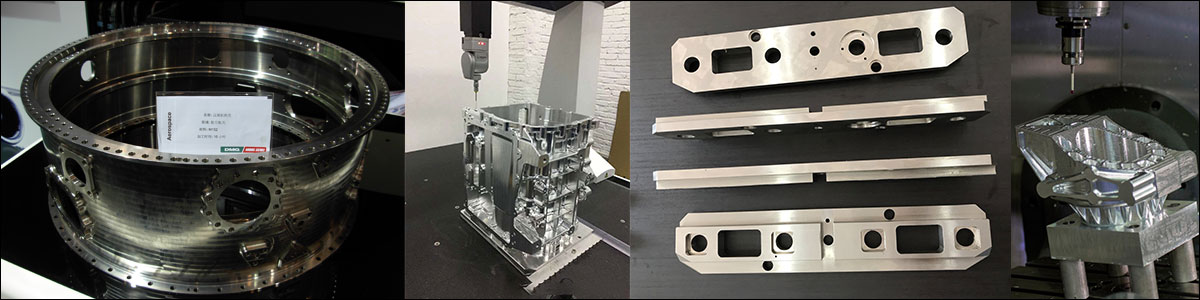

PRECISION NITRONIC-60 MACHINED PARTS

non-standard nitronic-60 parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from Nitronic 60. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. NiTroNiC60 is a good corrosion-resistant alloy with good toughness at low temperatures, particularly outstanding corrosion resistance, excellent resistance to seizure, high strength and excellent combination of high temperature oxidation resistance. This steel also has excellent resistance to high temperature oxidation and low temperature impact toughness. One of its most prominent features is wear resistance. This steel also has excellent wear resistance similar to inconel718 at 600 ° C. Compared with other austenitic stainless steels and duplex stainless steels, it has excellent cavitation resistance and can replace the wear-resistant alloy containing Co. Nitronic 60 has a machining cost factor of 9.0 when compared to steel 12L14. It can be readily welded. Nitronic 60 does not respond to heat treatment, but can be cold worked or case hardened to improve hardness. |

|

|

|

|

|

|

|

|

|

Contact our Nitronic-60 Machining services machinists today to discuss the specifics of your complex parts. |

Nitronic-60 Machining Industries & Applications

- ▶ Bushings

- ▶ Pins

-

▶ Shafts

-

▶ Pump and valve components

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminum, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;