PROTOTYPING CNC MACHINE SERVICES FOR MONEL PARTS

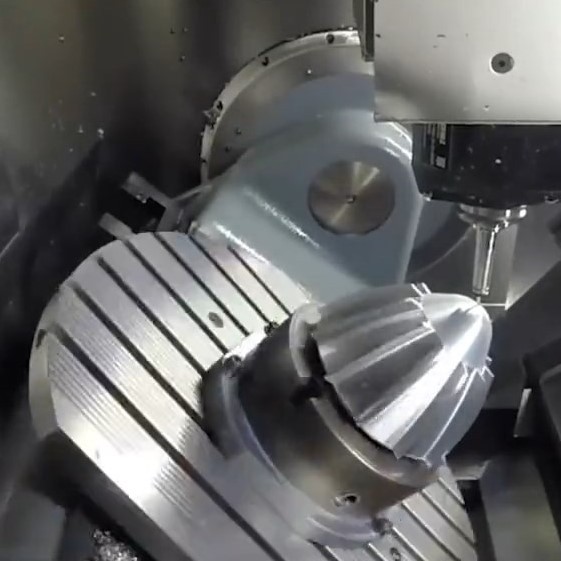

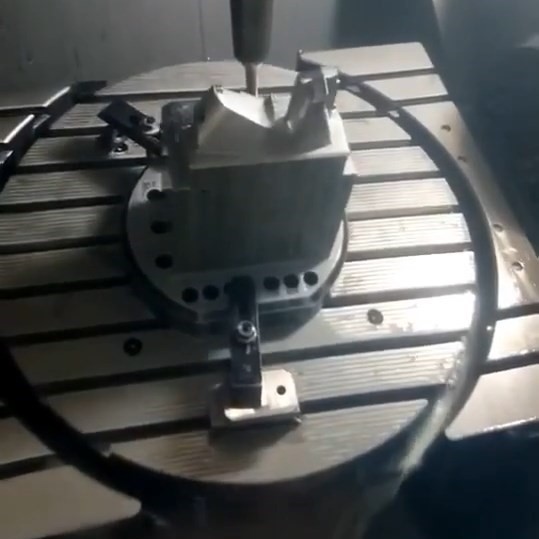

Simple to complex part cnc & swiss machining services for Monel component.

|

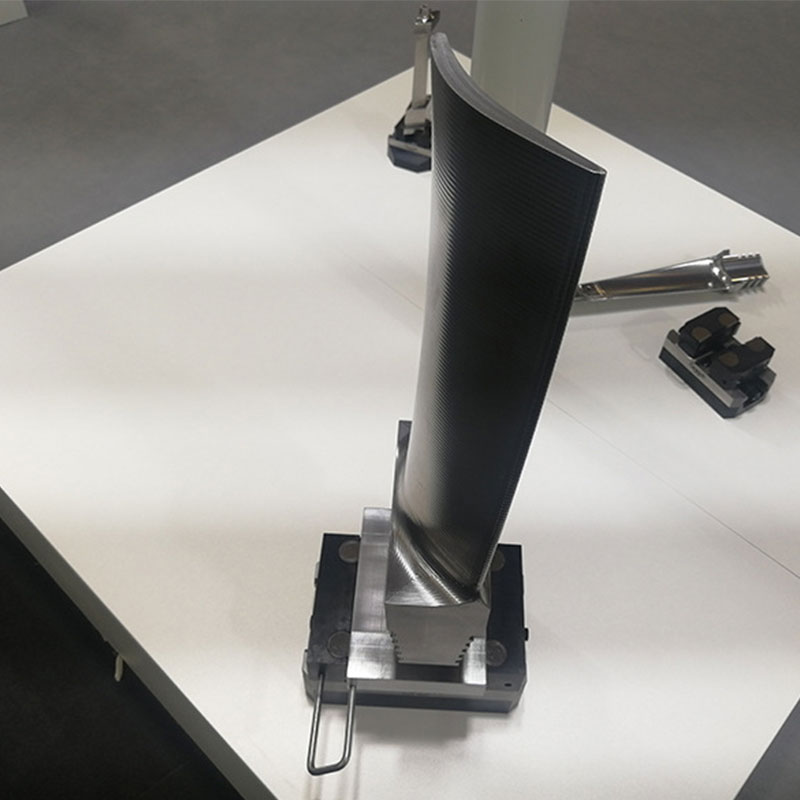

Monel is a corrosion-resistant alloy with the largest dosage, the most versatile use, and excellent comprehensive performance. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, as well as hot concentrated alkali. It is also resistant to corrosion by neutral solutions, water, seawater, atmosphere, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracking and has good cutting performance. PTJ Shop has over 10 years of experience working with Monel. We machine all forms of Monel including forgings, bar stock and castings. Our manufacturing experts are familiar with the unique properties of Monel. They account for details such as adjusting feed rate and depth of cut to maximize efficiency while maintaining the part’s dimensional stability. |

|

|

|

|

|

|

|

|

|

View PTJ Shop Machining Monel Case studies,Contact our custom monel services machinists today to discuss the machinability of your complex parts. |

|

|

|

Mechanical Properties Of Monel Alloy

|

Brand

|

σbMPa

|

δ(%)

|

HRC

|

Si %

|

|||||

|

Monel 400 (cold-drawn state) (comparison)

|

715

|

19

|

20

|

< 0.5

|

|||||

|

Monel K500 (cold-drawn state) (comparison)

|

820

|

21

|

26

|

< 1

|

|||||

|

High Silicon Monel (as-cast)

|

1012

|

3.2

|

34

|

3.9-4.7

|

|||||

|

High silicon Monel solution + aging

|

1250

|

20

|

41

|

3.8-4.5

|

|||||

|

High silicon Monel aging treatment

|

1300

|

10

|

47

|

3.8-4.5

|

|||||

|

Chemical composition of alloy (wt%)

|

|||||||||

|

Cu

|

Si

|

Fe

|

Mn

|

Ni-Co

|

Impurity content≤ (wt%)

|

Sum of impurities

|

|||

|

29.0-31.0

|

3.9-4.7

|

1.5-2.5

|

0.8-1.5

|

margin

|

Mg 0.10

|

Al 0.30

|

C 0.20

|

S 0.02

|

0.50

|

The Application Of Monel Alloy Material

- ▶ Machining Monel 400 :It is a corrosion-resistant alloy with the largest dosage, the most versatility and excellent comprehensive performance. This alloy has excellent corrosion resistance in a fluorine gas medium, and also has excellent corrosion resistance to hot concentrated alkali. It is also resistant to corrosion by neutral solutions, water, seawater, atmosphere, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracking and has good cutting performance. The alloy has excellent corrosion resistance in fluorine gas, hydrochloric acid, sulfuric acid and their derivatives

- ▶ Machining Monel K500 : Monel K-500 has the same corrosion resistance as Monel 400, but has higher mechanical strength and hardness. Has good heat resistance and corrosion resistance and long-term tissue stability. Mainly used to manufacture turbine blades and gas turbine blades with an operating temperature below 750 ° C on aircraft engines; used to manufacture fasteners and springs on ships; pumps and valve parts on chemical equipment; and scraping blades on papermaking equipment Wait.

- ▶ Machining Monel R-405 : R-405 performance is similar to Monel 400, and the processing performance is better

- ▶ Machining Monel 404&401 : These two alloys are mainly used in the electronics and electrical industries

View more high temperature and special composite alloy machining parts on our Gallery Page

We are proud to serve as our customer's single point of contact throughout their manufacturing process.

PTJ Shop is ISO9001:2015 CERTIFIED,For more information or requests of your monel ,please send email to :sales@pintejin.com.give us a try,we are ready to quote your program today

|

|

|

|