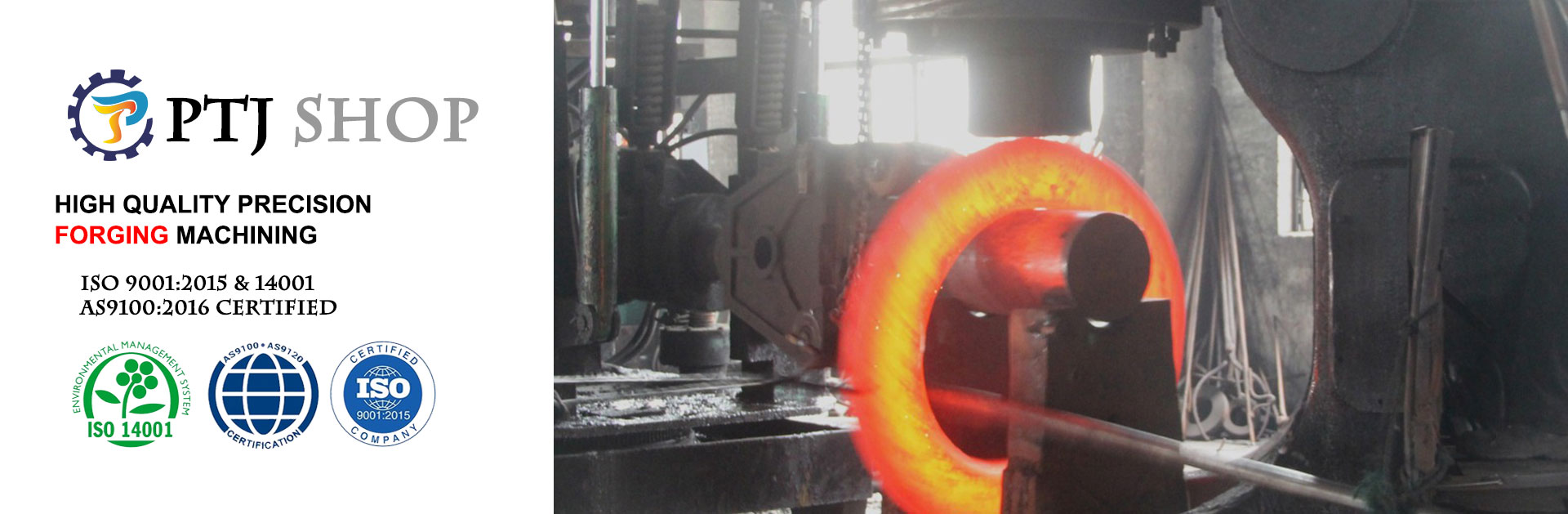

CHINA FORGING SERVICES FOR NON-STANDARD CUSTOM INDUSTRY

ISO 9001:2015 custom manufacturer of Closed die forgings & rolled ring forgings produced in aluminum, alloy & stainless steel grades.

|

Forging is one of the two major components of forging (forging and stamping) by using a forging machine to apply pressure to a metal blank to plastically deform it to obtain a forging having a certain mechanical property, a certain shape and size.

PTJ Shop Supply Custom metal forging services. Wide variety of forging methodologies including closed die forgings weighing from 0.5 to 500 lbs. and open die forgings ranging in sizes up to 10,000 lbs. Materials include steel, aluminum, bronze, nickel, titanium, corrosion resistant, and high temperature alloys. Various capabilities include pressing, plating, polishing, heat treating, machining, metal forming, stamping, assembly and product/metallurgical testing. Additional services include assembly, casting, design, engineering, fabrication and tooling. Aerospace, medical, automotive, mining, petrochemical and other industries served. Meets ASTM, SAE and AISI standards.

We do not offer off-the-shelf, standard product. Rather, we are custom job shop for metal components. We manufacture parts as designed by our customer. We also have multiple design engineers and a PhD Metallurgist on-staff to assist with processing RFQs with unique material or processing requirements or casting-to-forging or hog-out-to-forging conversion exploratory quotes.

|

|

|

|

|

|

|

|

Contact our forging services enginers today to discuss the specifics of your complex parts.

|

1.Manufacturer of cold forgings including cold-headed forgings.

Cold forgings include forward & backward extrusions, tube extrusions, hex & twelve point, square & double D, spline, upsetting, & coining cold forgings. Cold forgings are available in alloy steel, aluminum bronze, copper, copper alloy, brass & bronze, & carbon steel.

2. ISO 9001:2015 and TS16949:2009 certified custom manufacturer of hot forgings.

Carbon steel, alloy steel, tool steel and stainless steel materials used. Various capabilities include annealing, normalizing, tempering, nitriding, carbonitriding, anodizing, milling, drilling, honing and lapping. Automotive, electronic, furniture, construction, telecommunication, aerospace and other industries served.

|

|

|

|

|

|

High Accuracy

|

Quick Quote& Service

|

Fast Delivery

|

Custom Finishes

|

Precision Machines

|

Addition Services

|

|

Contact our Forging Shop to discuss your custom part needs today.

|

China Forging Capabilities

ISO 9001:2015 certified. Custom manufacturer of closed die, drop, press, hammer, near-net and net forgings made from carbon/alloy steel, stainless steel and titanium. Forging capacity ranges up to 4,000 tons. Capable of producing complex parts. Value added services such as heat treating, sawing, plating/painting, hardness testing, shot blast cleaning and assembly offered.

-

▶ Open Die Forgings

-

▶ Stainless Steel Forgings.

-

▶ CNC Machining.

-

▶ CNC Milling and Turning

-

▶ Fast Competitive Quotes.

-

▶ Quick On-Time Deliveries.

-

▶ Outstanding Delivery Performance.

-

▶ Unmatched Customer Service

-

▶ Fully Equipped Machine Shop

-

▶ In-House Heat Treating

-

▶ Mechanical & Non-Destructive Testing

-

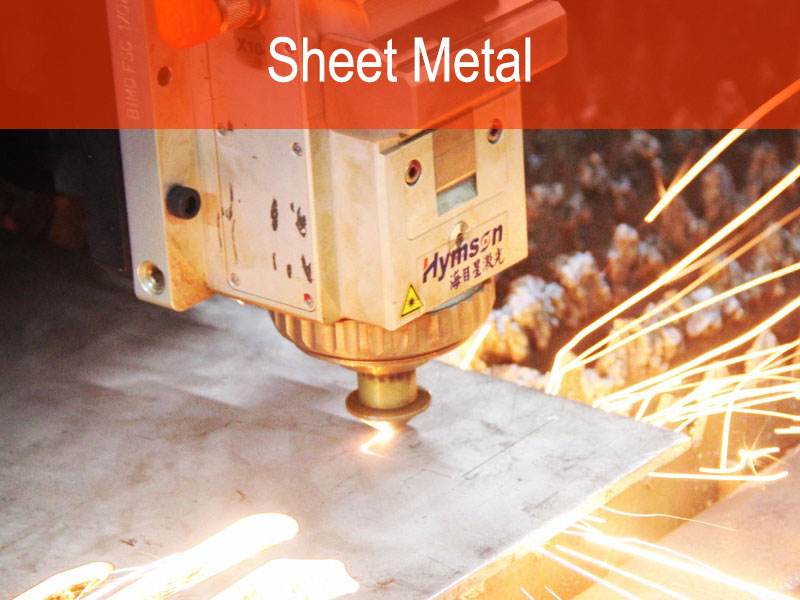

▶ Laser Cutting

-

▶ Flexible Production Schedule

-

▶ Attention To Detail

-

▶ An Esprit CAD/CAM system to precisely produce the most elaborate geometries (complete equipment list)

View more machining technology on our Gallery Page

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s view the other machining technology and learn more calture about PTJ Hardware.