PROTOTYPING CNC MACHINE SERVICES FOR THE MEDICAL INDUSTRY

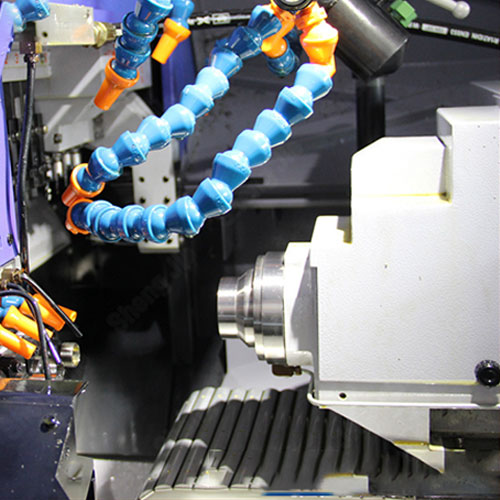

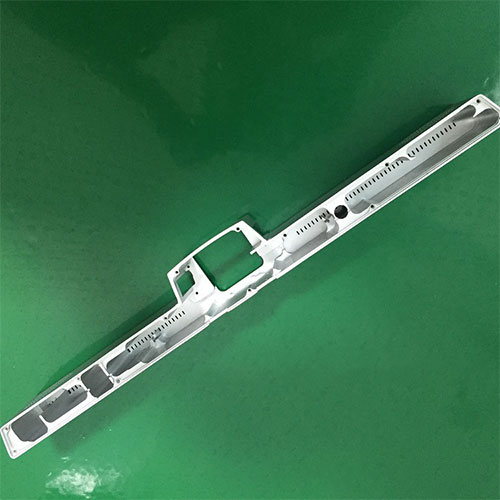

Simple to complex part turning and milling machining services for Medical industries.

|

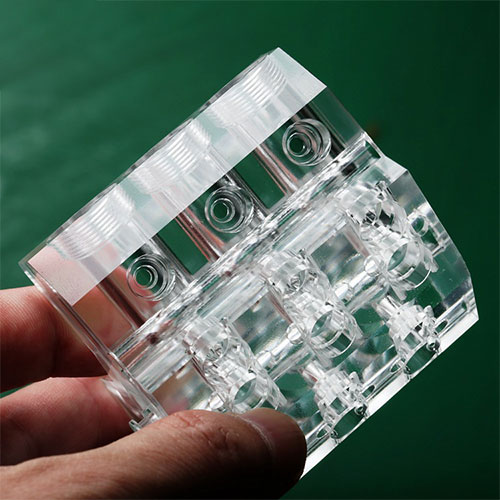

PTJ Shop Supply Precision specialty and micro CNC machining services for the medical industries. Works with various exotic metals such as aluminum, magnesium, iron, steel, carbon fiber, platinum, cobalt, yttrium, chrome, titanium and tungsten. Capable of micromachining parts under 0.005 in. size and 0.002 to 0.30 in. dia. Medical machining is suitable for hearing aids, cochlear implants, prosthetic parts, no touch door opener and surgical tools. Our medical parts precision machining service offers our clients confidence in the products they receive. Confidence is a uniquely meaningful term if you are a designer or manufacturer of medical devices. The PTJ name is a byword in medical manufacturing. Thanks to our trusted reputation for meeting exceptional requirements for intricate and highly complex components, we deliver the supply reliability our medical customers can’t live without. Machining can be done on parts up to 200 in. size and +/- 0.0005 in. tolerances. Ferrous and non-ferrous materials handled. Large precision parts, cylinders, castings, connecting rods, weldments, and housings can be machined. Other capabilities include precision CNC milling, boring, drilling, tapping, honing and grinding. ITAR registered. |

|

|

|

|

|

|

|

|

|

Contact our medical part machinists today to discuss the specifics of your complex parts. |

1.AS9100 Rev. B & ISO 9001:2015 certified custom manufacturer of medical models, plans, parts & supplies including dampers.

Non-standard custom medical devices dampers are available in various series with specifications including damping rates ranging from 0.2 lbs./rad./second to 300 lbs./rad./second, friction torque ranging between 4 in. oz. & less than 12 in. oz., temperature ranging from minus 54 degrees C to plus 74 degrees C, 90 degrees shaft rotation & weight ranging from 3.75 oz. to 11 oz. Meets MIL-I-45208 Specs.2.Sheet metal fabricator with experience in the medical industry.

Sample products include turnkey sterilization cases & trays & components and weldments for patient handling & monitoring equipment. Capabilities feature fully-automated CNC laser cutting, CNC punching, CNC panel bending & 5-axis laser welding along with conventional fabricating processes. Services include product development, 24-hour prototyping, & inventory management. Materials include carbon steel, stainless steel, & aluminum up to 3/8 in.3.Custom manufacturer offering CNC wireforming services.

Straightening and cutting services are also offered. Wire diameters range from 0.048-0.625 in. Works with various grades of steel, carbon steel, stainless steel and aluminum. Secondary services include end chamfering, flattening, swaging, hole drilling/punching, end threading and welding. Finishing services including electroplating are also offered. Serves the construction, consumer/industrial manufacturing, furniture, nursery/horticulture and steel industries.Behind it all is a knowledgeable, responsive staff of people, and a quality heritage born when quality was a matter of pride as well as metrics. We fully share our customers’ perspective: when lives depend upon it, nothing but a total commitment to excellence will do.

To sample this commitment firsthand, contact us to discuss your next medical machining project with a PTJ Manufacturing specialist.

|

|

|

|

|

|

|

High Accuracy |

Quick Quote& Service |

Fast Delivery |

Custom Finishes |

Precision Machines |

Addition Services |

|

|

Contact our CNC Machine Shop to discuss your medical part needs today. |

Taking advanced materials&process to new heights

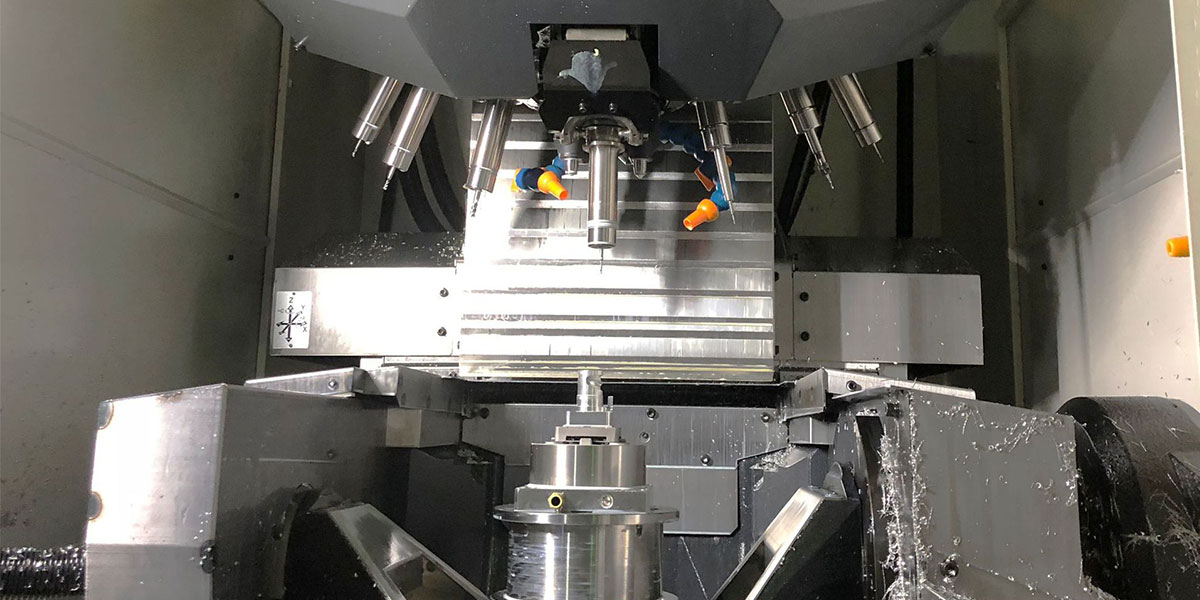

PTJ Machining recognizes that medical machining requires strict specifications, strong and durable materials&process, and also lot & batch traceability.Four-axis horizontal CNC machining services for medical devices applications. Materials include steel, stainless steel, aluminum, titanium, Inconel® and other alloys. Capabilities include machining with envelope size up to 72 in. x 48 in. x 48 in., CNC lathe work with swing parts up to 98.5 in. x 256 in. length, horizontal boring with machining envelopes up to 150 in. x 98 in. x 84 in. and deep hole drilling. CAD/CAM programming services are also available.

Medical Machining Capabilities

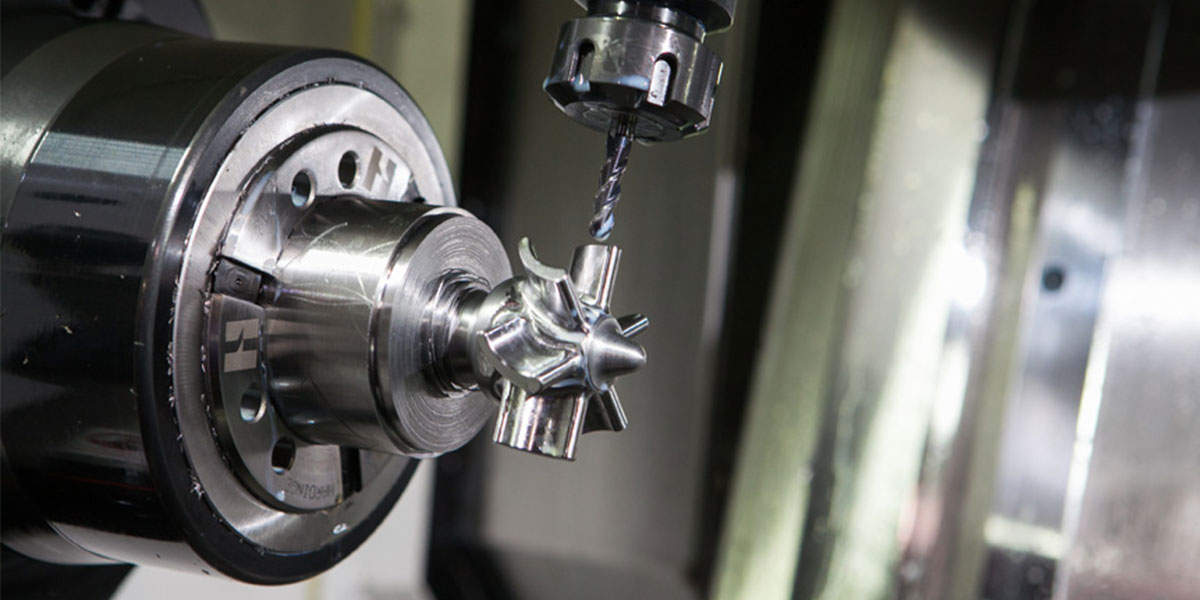

The professionals at PTJ Shop can manufacture precise components for the medical industry with our high quality CNC Swiss lathes. We understand the aviation industry has a constant high demand for the latest and best in hi-tech precise components, and our Swiss lathes provide the very best in aviation parts made with the highest quality materials and the tightest tolerances.-

▶ Exceptionally precise CNC Swiss machining

- ▶ Multi spindle cam automatics

-

▶ 5-axis machine centers for CNC turning and milling

-

▶ An Esprit CAD/CAM system to precisely produce the most elaborate geometries (complete equipment list)

CNC MACHINING MEDICAL CASE STUDIES

TESTIMONIALS

PTJ's friendship with customers around the world in the past decade

——————

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s watch the videos and learn more calture about PTJ Hardware.

● Cnc Machining Electronic Parts

● Cnc Machining Automotive Parts

● Cnc Machining Oil & Energy Parts

● Cnc Machining Aircraft Parts

● Learn more detail for Machining Field

——————

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s watch the videos and learn more calture about PTJ Hardware.

● Cnc Machining Electronic Parts

● Cnc Machining Automotive Parts

● Cnc Machining Oil & Energy Parts

● Cnc Machining Aircraft Parts

● Learn more detail for Machining Field