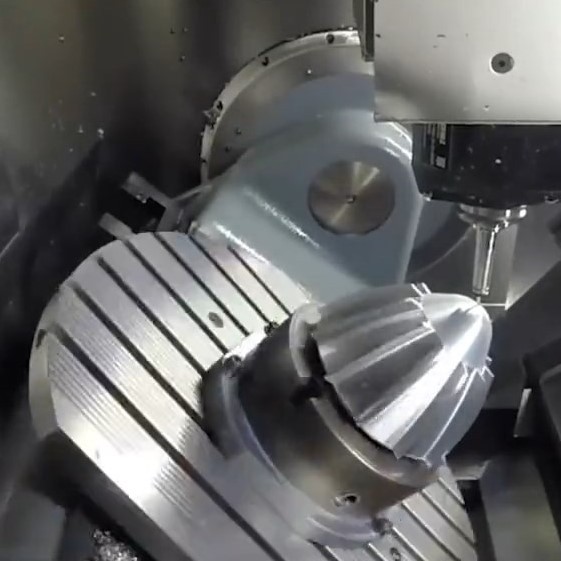

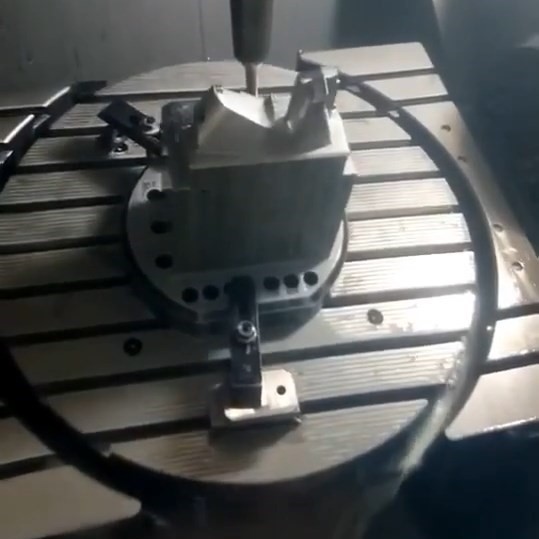

PROTOTYPING CNC MACHINE SERVICES FOR KOVAR PARTS

Machining Kovar | Kovar f15 And Fe Ni Co glass sealing alloy Machining Service With ceramic inserts

|

Kovar alloy is also called 4J29 alloy. The results show that the linear expansion coefficient of the alloy is similar to that of borosilicate hard glass at 20-450 ℃, the Curie point of the alloy is higher, and the microstructure of the alloy is stable at low temperature. The oxide film of the alloy is compact and can be well infiltrated by glass. It does not interact with mercury and is suitable for use in instruments containing mercury discharge. It is the main sealing structure material of electric vacuum device. Kovar metal is a typical Fe Ni Co hard glass sealing alloy in the world. After long-term use in aviation factory, the performance is stable. It is mainly used for glass sealing of electric vacuum components such as transmitting tube, oscillating tube, igniting tube, magnetron, transistor, sealed plug, relay, outgoing line of integrated circuit, chassis, shell, bracket, etc. In application, the selected glass should match the expansion coefficient of the alloy. The stability of low temperature structure was strictly tested according to the temperature. Appropriate heat treatment should be carried out in the process of processing to ensure that the material has good deep drawing drawing performance. When forging material is used, its air tightness should be strictly checked. PTJ has a reputation for machining quality parts from Kovar.PTJ Shop has the 10 years experience and tips for machining kovar parts.Choose PTJ for a quality, cost effective result. Request a quote now! |

|

|

|

|

|

|

|

|

|

View PTJ Shop Machining Kovar Case studies,Contact our custom invar services machinists today to discuss the machinability of your complex parts. |

|

|

|

|

|

|

|

|

|

|

|

|

Machining Properties Of Kovar

- ▶ After heat treatment according to 1.5 and freezing at - 78.5 ℃, no martensite should appear for 4H or more. However, when the composition of the alloy is different, the transformation from austenite (γ) to acicular martensite (α) will take place at room or low temperature, accompanied by volume expansion effect.

-

▶ The expansion coefficient of the alloy increases correspondingly, resulting in a sharp increase in the internal stress of the sealing parts and even partial damage. The chemical composition of the alloy is the main factor affecting the stability of low temperature microstructure.

- ▶ It can be seen from the Fe Ni Co ternary phase diagram that nickel is the main element to stabilize the γ phase, and higher nickel content is beneficial to the stability of the γ phase.

-

▶ With the increase of total deformation rate, the microstructure tends to be more stable. The segregation of alloy composition may also result in the local phase transformation from γ to α. In addition, the coarse grains can also promote the transformation from γ to α.

View more high temperature and special composite alloy machining parts on our Gallery Page

We are proud to serve as our customer's single point of contact throughout their manufacturing process.

PTJ Shop is ISO9001:2015 CERTIFIED,For more information or requests of your Invar ,please send email to :sales@pintejin.com.give us a try,we are ready to quote your program today

|

|

|

|