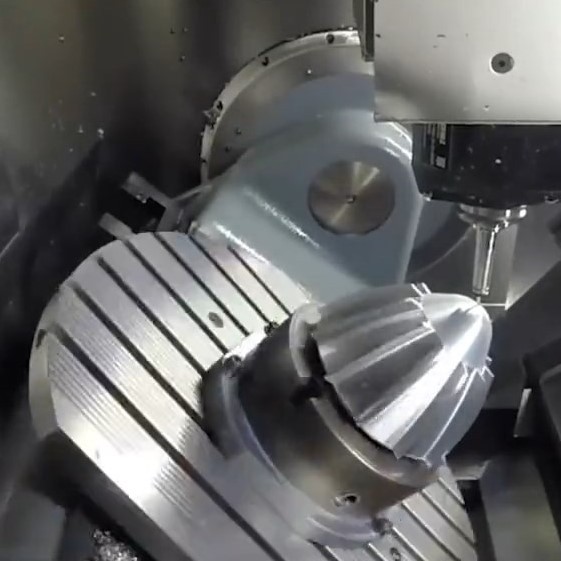

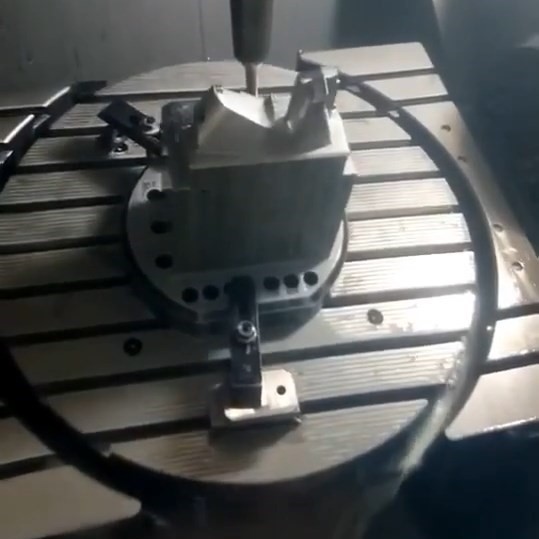

PROTOTYPING CNC MACHINE SERVICES FOR INVAR PARTS

Machining Invar | Invar 36 And Nickel-Iron Alloy Machining Service

|

Invar, iron alloy containing 35.4% nickel.It has a very low thermal expansion coefficient at room temperature (between -20°C and 20°C, with an average value of about 1.6×10-6/°C).Invar is known as the king of metals and is precision instrument and Indispensable structural materials.The application of INVAR is extended to aerospace remote sensors, precision laser equipment, optical measurement systems and waveguide structures, various microscopes, support systems for large lenses in astronomical telescopes, and various scientific instruments that require lenses. Invar cannot be strengthened by heat treatment, and its characteristics are similar to austenitic stainless steel, but it is more difficult to machine than austenitic stainless steel. The main performance in cutting is high cutting force and high cutting temperature. In the processing process, it also has soft, viscous characteristics and great plasticity, is not easy to break chips, aggravates the wear of the tool, and reduces the machining accuracy of the workpiece, so high-performance tools must be used. For over 10 years, PTJ has provided Invar machining services to a variety of industries including aerospace and other high-end industries. Our machined Invar alloy parts (include invar 36)are designed and manufactured for high strength and impact applications and can meet your project's needs. Request your invar material machining quote today! |

|

|

|

|

|

|

|

|

|

View PTJ Shop Machining Invar Case studies,Contact our custom invar services machinists today to discuss the machinability of your complex parts. |

|

|

|

|

|

|

Machining Properties Of Invar

- ▶ The coefficient of thermal expansion is small, the average expansion coefficient is 1.6×10-6/℃ at room temperature, and it is relatively stable at room temperature -80℃~230℃.

-

▶ The strength and hardness are not high, the tensile strength is about 590Mpa, the yield strength is about 410Mpa, and the Brinell hardness is about 141HBS.

- ▶ The thermal conductivity is low, 10W/m.K, which is only about 1/4 of the thermal conductivity of 45 steel.

-

▶ Plasticity, toughness, elongation, reduction of area and impact toughness are all high, elongation δ=30~45%, shrinkage δ=50~70%. Impact toughness αK=130-310 J/cm2.

View more high temperature and special composite alloy machining parts on our Gallery Page

We are proud to serve as our customer's single point of contact throughout their manufacturing process.

PTJ Shop is ISO9001:2015 CERTIFIED,For more information or requests of your Invar ,please send email to :sales@pintejin.com.give us a try,we are ready to quote your program today

|

|

|

|