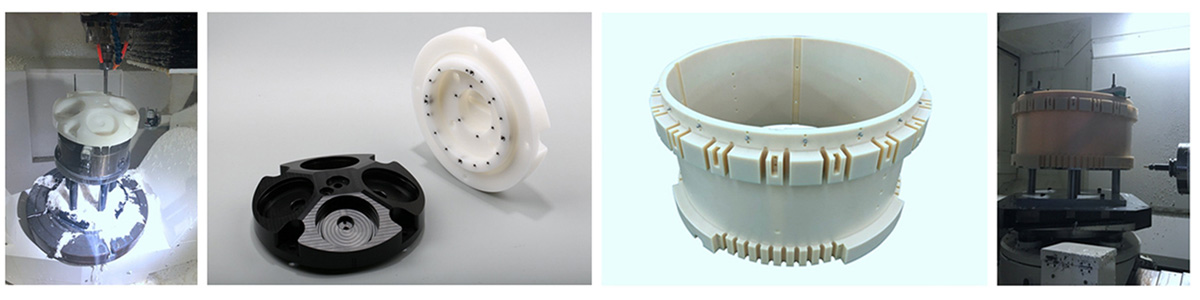

PRECISION CERAMIC CNC MILLED AND TURNED PARTS

Ceramic Plastic non-standard parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from Ceramic. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. Ceramic grinding refers to the surface processing of ceramics after forming or sintering with abrasives. Ceramic grinding machining is divided into fixed abrasive machining such as grinding, honing, ultra-fine machining, sandpaper abrasive machining, and free abrasive machining such as sanding, polishing, drum machining, ultrasonic machining, and jet machining. Ceramic has a machining cost factor of 0.7 when compared to steel 12L14.

|

|

|

|

|

|

|

|

|

|

View PTJ Shop Ceramic CNC Machining Case studies,Contact our custom plastic services machinists today to discuss the specifics of your complex parts. |

Ceramic Machining Industries & Applications

- ▶ Gears

-

▶ Bearings

- ▶ Bushings

- ▶ Sprockets

-

▶ Electronic components

View more plastic machining parts on our Gallery Page

PTJ has a reputation for successfully machining the plastic other producers prefer not to handle. Customers can confidently design with new materials, secure in the knowledge that PTJ Shop can machine even the most exotic,Ceramic Materials for a quality, cost effective result.- ▶ High grade plastic materials : PI,PAI,PEEK,PCTFE,Ceramic,etc;

- ▶ Medium grade plastic material : PEI,PPS,Unilate,PVDF,etc;

- ▶ Commonly used cost-effective plastic materials : ABS,PMMA,PC,PTFE,PET,UPE,PA6,POM,UHMW,PP,PVC,PUetc;