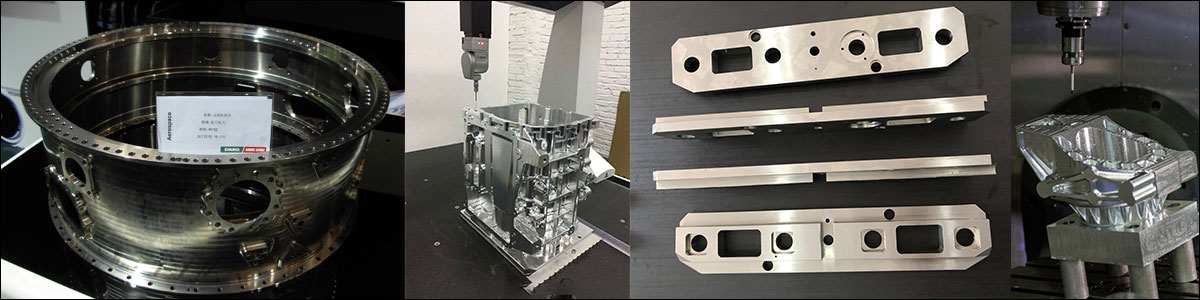

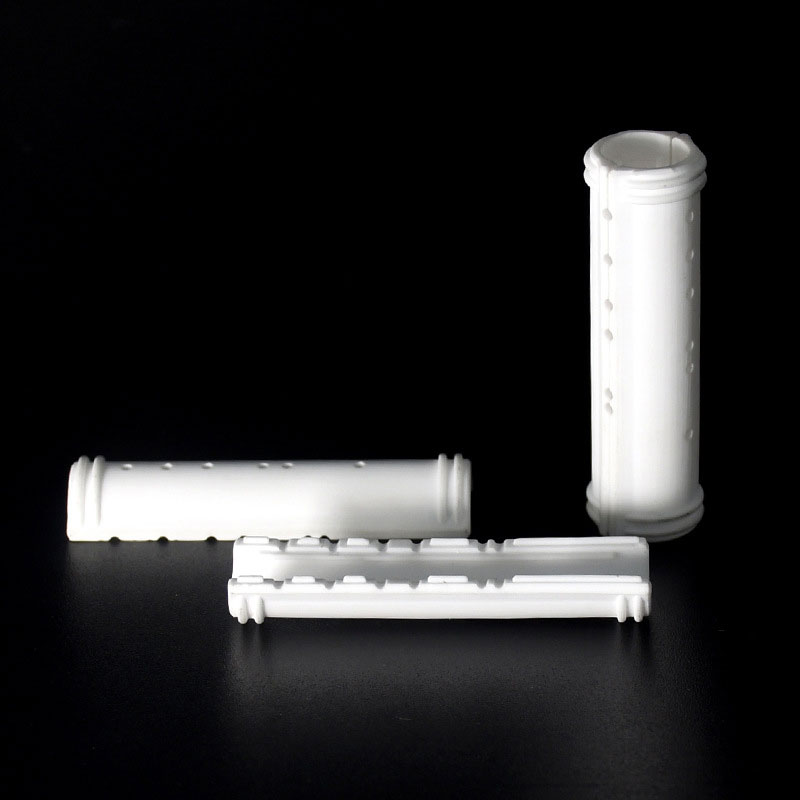

PRECISION CERAMIC MATRIX MACHINING PARTS

ceramic matrix non-standard parts fabrication services for small, large and heavy components.

|

Technical ceramic provide greater flexibility in design, available in larger component sizes & offer similar mechanical properties. ISO 9001:2015 & AS9100D certified precision manufacturer, ITAR registered. Supplier of machine-ready ceramic blanks. Materials available include Macor®, glass bonded mica, and boron nitride. Products include precision ground blanks, discs, and rods. Grinding capabilities include Blanchard, surface, and centerless grinding. Macor® is a machinable glass ceramic that features a unique microstructure. Glass bonded mica is composed of finely powdered electrical grade glass and precisely-sized natural and synthetic mica flakes. Boron nitride is a hot pressed solid with a hexagonal and platy crystal structure. Various properties include high operating temperature ranges, nonwetting properties, electrical resistivity, dimensional stability, coefficient of thermal expansion similar to most metals, and dielectric strength. Suitable for ultra-high vacuum environments, aerospace, nuclear, electrical insulation at high temps, semiconductor, and other applications. Call PTJ for your ceramic machined parts today!

|

|

|

|

|

|

|

|

|

|

View PTJ Shop Ceramic Matrix Machining Case studies,Contact our custom services machinists today to discuss the specifics of your complex parts. |

|

|

|

Ceramic Matrix Machining Industries & Applications

- ▶ Gears

-

▶ Bearings

- ▶ Bushings

- ▶ Sprockets

-

▶ Electronic components

View more machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminum, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zin,etc;

- ▶ High Grade Machining Materia : Magnesium, superalloy, heat resistant steel etc;