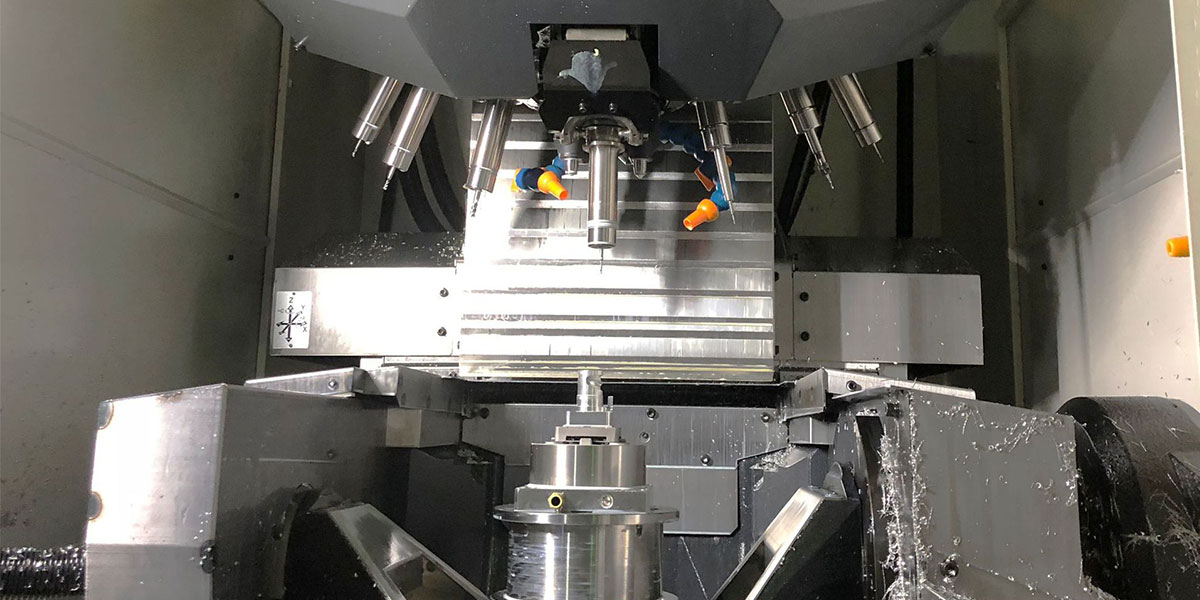

PRECISION BRASS CNC MILLED AND TURNED PARTS

Brass non-standard parts fabrication services for small, large and heavy components.

|

3, 4 and 5-axis precision CNC machining services for brass. Capable of machining parts from 0.004 in. to 0.012 in. wire dia. Machining processes include milling, drilling, turning, threading, tapping, knurling, reaming and cutting. Secondary services such as assembly, bending, countersinking and heat treating provided. Prototype and low volume production offered. Suitable for insert, fixture, sprocket, gage, gear, extrusion, cam and electrode applications. ISO 9001:2015 certified brass automatic screw machining services. Finishing processes include plating, coating, heat treating, bagging and painting.Aerospace, automotive, biomedical, medical device, military, mining and transportation industries served.Products meet Mil-I-4528 standards & are QS 14000 compliant. Made in the China PTJ has been making precision turned brass components since the late 2007's. Few materials are easier to machine than brass, so smart brass component buyers choose their brass parts supplier by using a simple decisive factor: who can I trust to deliver the machined brass products I need precisely when I want them? |

|

|

|

|

|

|

|

|

|

Contact our custom brass parts machinists today to discuss the specifics of your complex parts. |

1.Custom manufacturer of screw machine products & turned parts. .

Various products include bushings, collars, connectors, pins, shafts, spacers and valves. Alloy steel, aluminum, brass, bronze alloys, carbon steel, copper and stainless steel materials used. Maximum part length is 4 in., while the outer diameter can range from 5/16 in. to 4 3/4 in. Capabilities include screw machining services like boring, deburring, drilling, grinding, knurling, milling, polishing, reaming, and turning. Aerospace, agriculture, construction, automotive, electronic, electrical, medical, military and other industries served. NADCAP, ISO 9001:2008, AS9100, and TS 16949:2009 certified.2.Custom manufacturer of milled parts.

Materials include aluminum, beryllium, brass, carbon steel, cobalt, copper, iron, lead, ABS, acetal, nylon, PTFE and others. Capable of handling parts up to 12 in. L x 12 in. W x 12 in. H dimensions with +/-0.0001 in. tolerance. Various capabilities include cutting, threading, turning, drilling, tapping and reverse engineering. Secondary services include assembly, countersinking, pressing, reaming, plating, passivating, anodizing and others. Specialty, small to large run and high volume production can be done. Aerospace, agriculture, architectural, chemical, dental, marine and other industries served. Emergency and rush services available. Meets AS standards. On-time delivery.3.Ultra precision 5-axis CNC machining services for brass parts.

AS9100/ISO 9001 certified contract manufacturer.Capabilities include CNC milling, honing and welding. Surface grinding, deburring and lapping services are also available. Suitable for tight tolerances and complex geometries. CAD/CAM files accepted. On-time delivery.You are invited to experience this mission-critical capability firsthand. Contact us for a prompt response to your brass steel parts machining project.

|

|

|

|

|

|

|

High Accuracy |

Quick Quote& Service |

Fast Delivery |

Custom Finishes |

Precision Machines |

Addition Services |

|

|

Contact our CNC Machine Shop to discuss your brass part needs today. |

Brass Machining Benefits

Brass machining parts have several key advantages compared to machining other materials. Brass turned parts and components are durable, cost-efficient, and even create a tighter seal for fittings. In addition, brass machining and turning parts have a high heat and corrosion resistance! More importantly, PTJ's brass screw machine parts are easy to machine and join, and made to your specifications and standards!.

Other Brass Machined Process In PTJ Shop

- ▶ Brass die casting

-

▶ Brass sand casting

- ▶ Hot and cold Brass forging

-

▶ Manufacturer of sheet metals including Brass panel

- ▶ Powder metallurgy

- ▶ Brass stamping (complete equipment list)

Commonly Machined Brass Material

Why Choose PTJ for Machined Brass Components?

- ▶ Whether it takes a stocking plan, KanBan or consignment program, PTJ delivers to suit your schedule. Backup inventories can be created to respond to fluctuations in production demand.

- ▶ PTJ can perform several operations simultaneously by utilizing equipment options in Swiss machining, multi-spindle machining and CNC turning, producing precision turned brass components at a fraction of the traditional cost.

- ▶ The experienced staff at PTJ carefully examines each new project to spot design amendments that lead to improved brass screw machine parts, material savings and faster turnaround times.

MACHINING BRASS CASE STUDIES

TESTIMONIALS

PTJ's friendship with customers around the world in the past decade

——————

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s watch the videos and learn more calture about PTJ Hardware.

● Prototype CNC Machining for Aircraft Parts

● Best Prices Machining Automotive Parts

● Cnc Machining Electronic Parts

● Precision Machining Custom Surgical tools

● Learn more detail for Machining Field

——————

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s watch the videos and learn more calture about PTJ Hardware.

● Prototype CNC Machining for Aircraft Parts

● Best Prices Machining Automotive Parts

● Cnc Machining Electronic Parts

● Precision Machining Custom Surgical tools

● Learn more detail for Machining Field