PRECISION BRASS 353 Eli MACHINED PARTS

non-standard brass 353 parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from Brass 353 alloy. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. Lead brass C35300 has good machinability, cold workability and poor hot workability. The lead brass C35300 is mainly used as a bearing cage, a watch clamp, an engraving plate, a gear, and a hose joint. Brass 353 has a machining cost factor of 0.7 when compared to steel 12L14. It is not ideal for welding or hot working, but is excellent for soldering and possesses better formability than Brass 360. Brass 353 can be annealed. Due to brass 353's excellent machinability and the high return value of scrap, the net cost of machining brass is competitive with steel. |

|

|

|

|

|

|

|

|

|

Contact our Brass 353 Machining services machinists today to discuss the specifics of your complex parts. |

Brass 353 Machining Industries & Applications

- ▶ Fittings

- ▶ Bearings

- ▶ Valve components

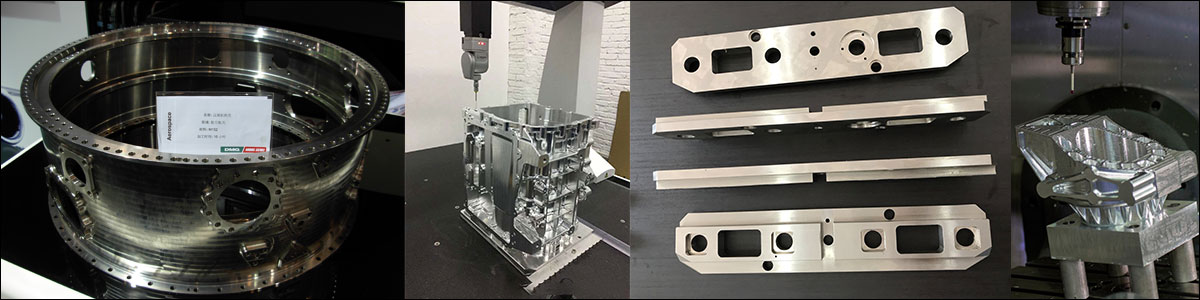

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;