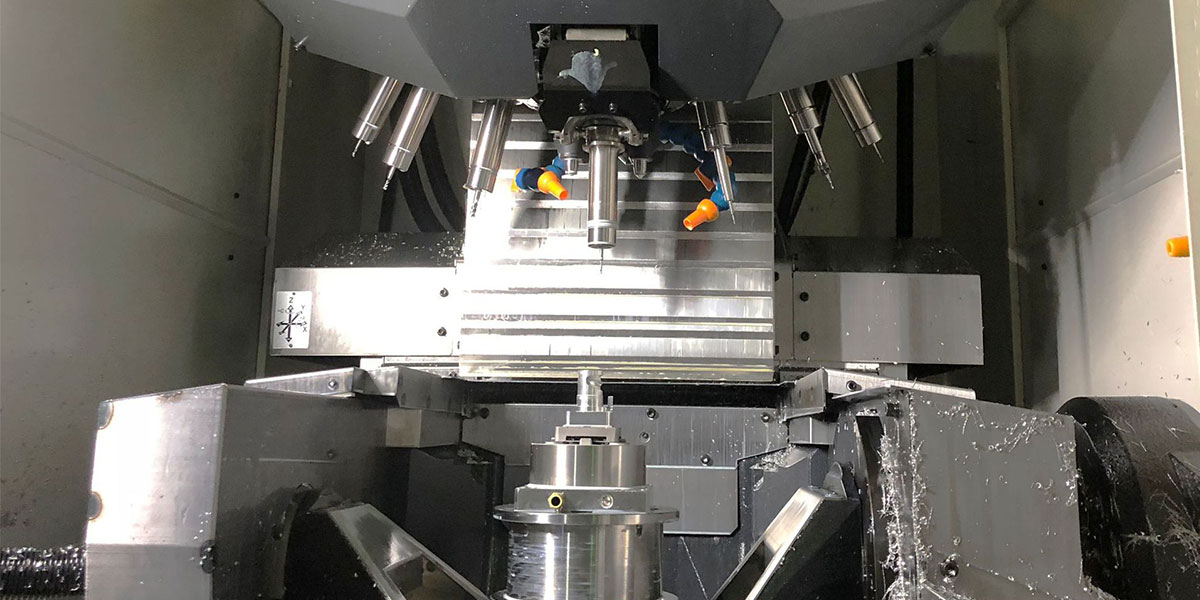

PROTOTYPING CNC MACHINE SERVICES FOR BIKE INDUSTRY

Simple to complex part turning and milling machining services for bike industries.

|

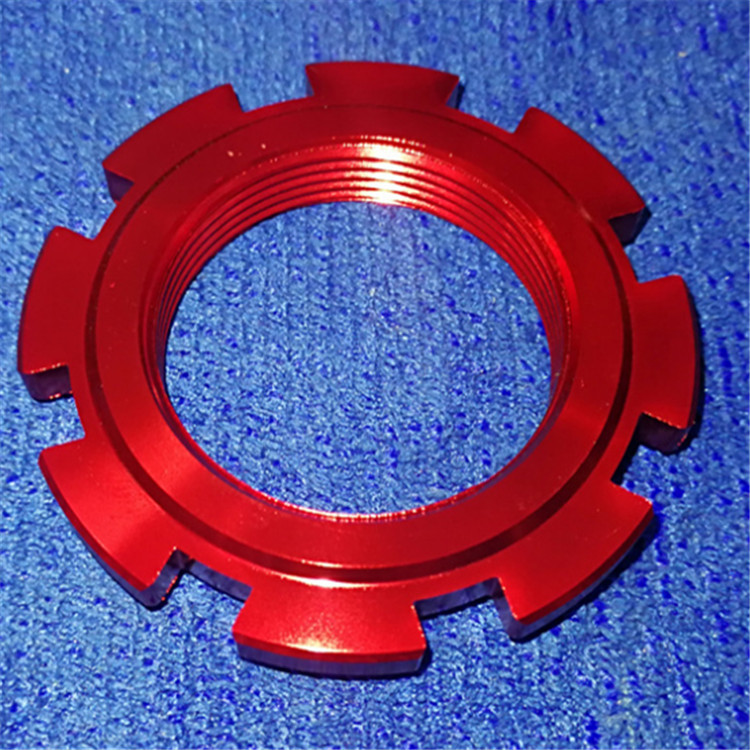

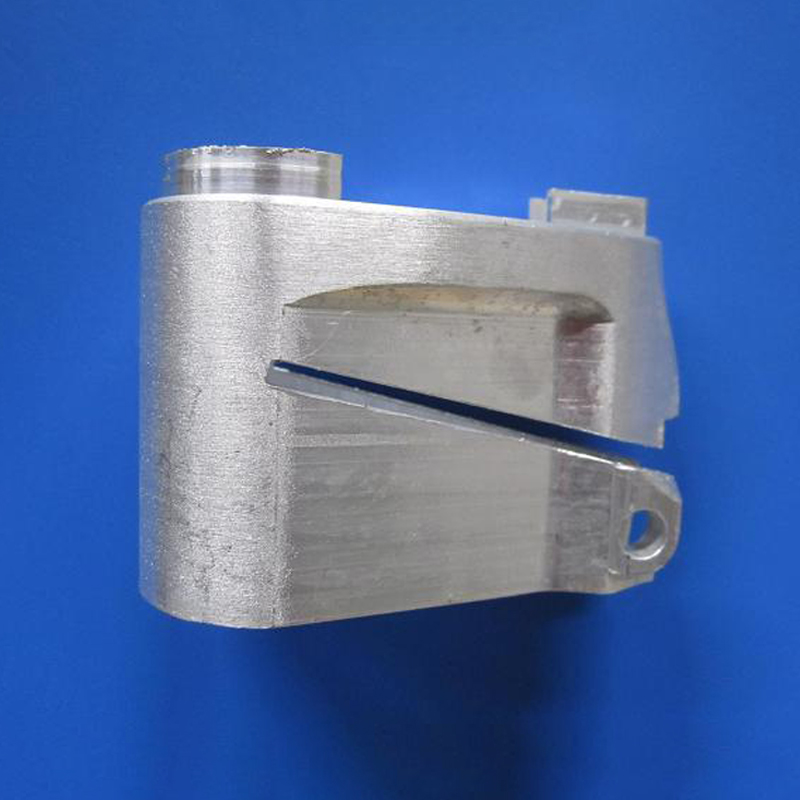

ISO 9001:2015 certified CNC OEM bike parts machining services. 3, 4 and 5-axis precision CNC machining services for the mini bike,sports bike, mountain bike,street bike,pocket bike,dirt bike etc. Works with aluminum, brass, bronze, copper, stainless steel, steel, titanium, zinc, ABS, acrylic and PTFE. Capable of machining parts up to 90 mm sizes with +/-0.400 mm tolerance. Processes include CNC milling and turning. Forged,Prototype and low, medium to high volume production offered. Suitable for hradware molding, rapid tooling, prototyping and end-use production applications. Capable of horizontal milling parts with 18 in. x 22 in. x 12 in. dimensions and turning parts with up to 13 in. diameter sizes. Available from prototypes to high-volume production runs.CAD design, tooling design, assembly, and surface grinding services are provided. |

|

|

|

|

|

|

|

|

|

Contact our bike part machinists today to discuss the specifics of your complex parts. |

1.Multi-axis screw CNC machining services for bike applications.

The exceptional precision of CNC Swiss machining, multi-spindle cam automatics, and CNC turning centers2.Metal manufacturing fabricator with experience in the custom bicycle parts industry.

The ability to machine materials other manufacturers won't, including copper, plastics and exotic alloys that meet the special requirements of advanced bicycle structure systems3.AS9100 Rev. B & ISO 9001:2015 certified custom manufacturer of bike parts machining

Deep experience complying with documentation and certification requirements, such as DFARS material source standards and compliance with ITAR controlsYou are invited to experience this mission-critical capability firsthand. Contact us for a prompt response to your bike parts machining project.

|

|

|

|

|

|

|

High Accuracy |

Quick Quote& Service |

Fast Delivery |

Custom Finishes |

Precision Machines |

Addition Services |

|

|

Contact our CNC Machine Shop to discuss your bike devices part needs today. |

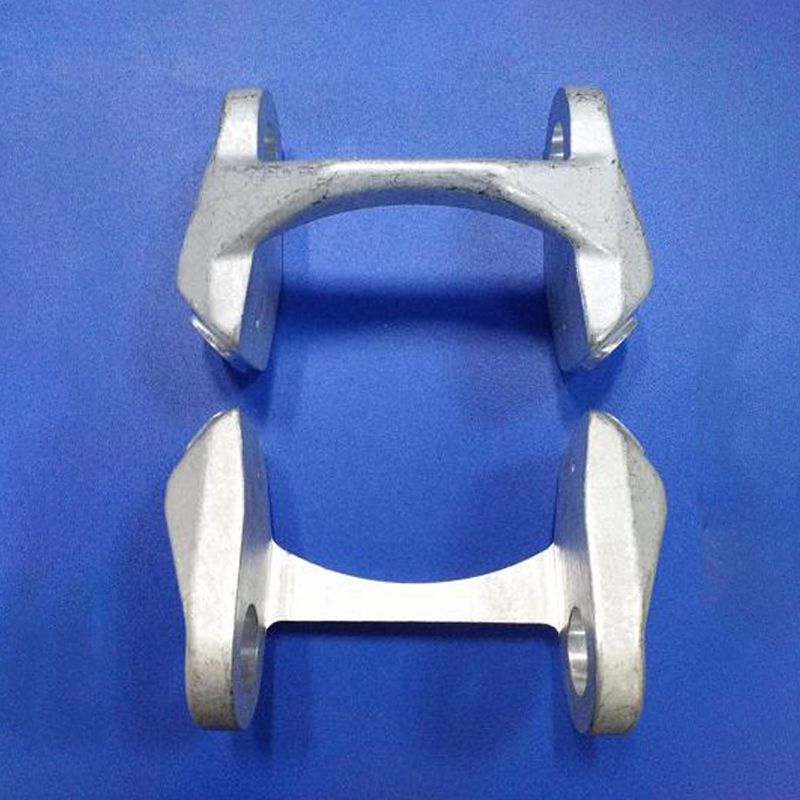

Taking advanced forging process to new heights

ISO 9001:2015 & ISO/TS 16949:2009 certified custom manufacturer of hot forged miniature and small parts. Features include corrosion resistance and fatigue resistance. Materials used include stainless steel, alloy steel and aluminum.Available with 2 cm W x 2 cm H to 2 m W x 2 m H sizes. Assembly, engineering, casting, conversion and metallurgical testing additional services offered. Capabilities include high volume and small parts fabrication. Secondary services include designing, engineering, mold making, double disc, centerless grinding, deburring, machining, oil impregnation and steam treating.

Bike Parts Machining Capabilities

The professionals at PTJ Shop can manufacture precise components for the bike industry with our high quality CNC Swiss lathes. We understand the bicycle industry has a constant high demand for the latest and best in hi-tech precise components, and our Swiss lathes provide the very best in bike parts made with the highest quality materials and the tightest tolerances.-

▶ Exceptionally precise CNC Swiss machining

- ▶ Multi spindle cam automatics

-

▶ 5-axis machine centers for CNC turning and milling

-

▶ An Esprit CAD/CAM system to precisely produce the most elaborate geometries (complete equipment list)

CNC MACHINING BIKE PARTS CASE STUDIES

TESTIMONIALS

PTJ's friendship with customers around the world in the past decade

——————

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s watch the videos and learn more calture about PTJ Hardware.

● Cnc Machining Aircraft Parts

● Cnc Machining Automotive Parts

● Cnc Machining Electronics Parts

● Cnc Machining Medical Parts

● Learn more detail for Machining Field

——————

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years.

Let’s watch the videos and learn more calture about PTJ Hardware.

● Cnc Machining Aircraft Parts

● Cnc Machining Automotive Parts

● Cnc Machining Electronics Parts

● Cnc Machining Medical Parts

● Learn more detail for Machining Field