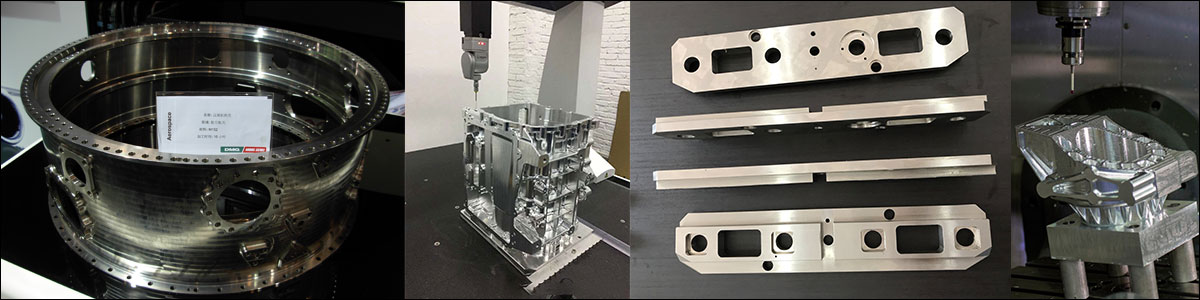

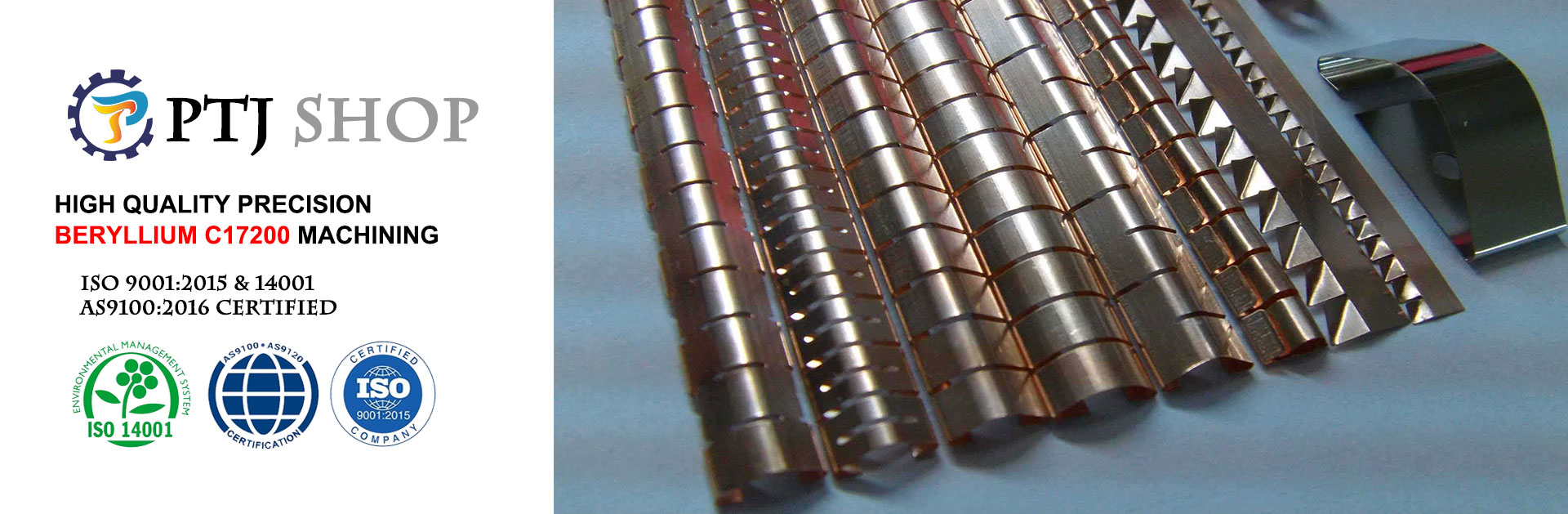

PRECISION BERYLLIUM C17200 MACHINED PARTS

non-standard beryllium copper 172 parts fabrication services for small, large and heavy components.

|

PTJ Shop has a reputation for machining quality parts from Beryllium Copper 172. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. Beryllium Alloy 172 has a good overall performance. Its mechanical properties, namely strength, hardness, wear resistance and fatigue resistance, rank first among copper alloys. Other conductive materials that are conductive, thermally conductive, non-magnetic, and spark resistant cannot be compared. In the solid solution soft state, the strength and electrical conductivity of Beryllium Alloy 172 are at the lowest value. After work hardening, the strength is improved, but the electrical conductivity is still the lowest value. After aging heat treatment, its strength and electrical conductivity increased significantly. The machinability, weldability and polishing performance of Beryllium Alloy 172 are similar to those of ordinary high copper alloys. BeCu 172 has a machining cost factor of 3.0 when compared to steel 12L14. It is good for soldering, brazing, forging, welding, and hot and cold working. BeCu 172 can be annealed. |

|

|

|

|

|

|

|

|

|

Contact our beryllium C17200 Machining services machinists today to discuss the specifics of your complex parts. |

Beryllium Copper Alloy 172 Machining Industries & Applications

View more alloy machining parts on our Gallery Page

Machine shop specializing in custom machined items. Numerous mills and lathes are used to hold tight tolerances. Small and large jobs are available.- ▶ Advantage Machining Materials : Aluminium, Stainless Steel, Brass,etc;

- ▶ Commonly Machining Materials : Copper, titanium, iron, zinc,etc;

- ▶ High Grade Machining Materials : Magnesium, superalloy, heat resistant steel etc;