Degradable water-soluble 3D printing support material

On November 13th, a team of researchers has developed a new material that is very suitable for use as a general-purpose water-soluble carrier for additive manufacturing (3D printing). Its thermal stability and strong adhesion characteristics make it an ideal support system for various building materials.

Most manufacturers understand how 3D printing enables them to produce stronger, lighter parts and systems. Although many different materials can be used to create 3D printed models, the most commonly used are thermoplastics such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA) and polycarbonate (PC). Complex thermoplastic parts and structures have bridges or overhangs and require support during the printing process. Since these supporting structures are not part of the model, they need to be deleted after printing. The subsequent processing step is very important because it will affect the final surface finish, strength and color of the printed part. And sometimes it is necessary to use harmful chemicals to damage the surface of the model and reduce productivity. Therefore, choosing the right material for the 3D printing support structure is crucial.

BREAKVS soluble support structure

There are two basic types of materials that can be used for supporting structures: separable and soluble. The separation support structure is usually constructed of materials similar to printed objects. After printing, the support can be removed by trimming, mechanical breaking or abrasion. All these steps increase the workload and therefore increase the time and cost. In addition, removing the 3D printing support structure may leave flaws on the surface of the model, or damage the model along with the structure. In addition, when using high-temperature materials, it is usually more difficult to remove the separation support.

The development challenge of soluble support

The development of water-soluble carriers is challenging. First, there are a limited number of commercially available resins that are truly soluble in water. Many water-soluble polymers are very brittle, which prevents them from turning into filaments. In addition, the use of traditional additives for plasticization often inhibits thermal stability and adhesion, which severely limits their use in 3D printing.

The first generation of soluble carriers has many problems. Some use harmful chemicals or strong acid or alkaline solutions. Although some of them are still widely used, resin technology has been developed, and there are now a large number of soluble support materials on the commercial market, including:

• Highly proprietary resins (Stratasys SR30, SR35, SR100, etc.)

• Resin based on commonly used PVA or polyvinylpyrrolidone (PVP)

• Cellulose, such as hydroxypropyl methylcellulose (HPMC)

• Exotic polybutylene glycol vinyl alcohol (BVOH)

However, none of these products are ideal for filaments because they are not thermally stable. There is now a better choice of materials.

Enough to dissolve filamentous water-soluble resin

Infinite Material Solutions recently developed a composite material that is both water-soluble and thermally stable. This "out-of-the-box" resin is a blend of natural carbohydrates and soft, tough and water-soluble polymers. The new material (trademark AquaSys™ 120) is unique because it is hard enough to be used as a support wire. This formulation is surprising because many pure carbohydrates and water-soluble polymers are too brittle to form usable filaments. Over the years, formulators have made many attempts to plasticize water-soluble resins in order to convert them into filaments. However, the addition of plasticizers usually greatly reduces the thermal stability of the base resin. In addition, plasticizers can inhibit the adhesion between materials, which severely limits their use in 3D printing. AquaSys 120 uses a highly complex process to produce 1.75 mm and 2.85 mm diameter filaments, which can be successfully used for various 3D printing platforms and materials.

Material benefits and compatibility

The various components of this new material have been widely used in industry for various applications ranging from packaging and drug delivery to cosmetics and personal care products. According to the information available for all individual components, the material is hydrophilic, biocompatible, biodegradable, non-toxic and non-carcinogenic.

This new filament material can be used in the most common 3D printing technologies, including molten filament manufacturing and direct material extrusion. It is also compatible with various materials, including polypropylene and hydrophilic and hydrophobic polymers. Compared with traditional PVA, it has excellent thermal stability and other advantages, which makes it a versatile, durable and environmentally friendly material for supporting wires.

These advantages include: • Dissolves in water faster than pure PVA • Can use a variety of materials for printing

• Has enhanced adhesion • Biodegraded faster than PVA

Thermal stability at many high temperatures

The leading PVA filament brand can be printed at a temperature of 215-225ºC, and the maximum base plate temperature is 60ºC. In addition, the AquaSys 120 filament can be printed at a temperature of 240-245ºC, and the maximum base plate temperature is 130ºC.

Adhesion characteristics

Being able to build materials that can adhere to soluble supports, and vice versa, is essential for successful 3D printing. Poor adhesion between the support and adjacent layers of building materials can cause peeling and printing failures. The new material has been designed with enhanced adhesion properties to solve this problem. It is compatible with various hydrophobic and hydrophilic materials used in filament-driven 3D printing platforms, and continues to be used with new building materials.

So far, AquaSys 120 has successfully tested polyamide (nylon), copolyester (CPE), acrylonitrile butadiene styrene (ABS), thermoplastic polyurethane (TPU), polycarbonate (PC) and polyolefin (such as Polypropylene (PP)). Compared with traditional PVA yarn, it has significant advantages, the latter has limited adhesion to CPE, ABS, TPU, PC and PP.

Solubility

In the head-to-head dissolution test of the same printed parts, the dissolution speed of the new filament material at room temperature (22°C) is twice that of the leading brand PVA, and the dissolution speed at high temperature (80°C) is six times faster. Unlike PVA, PVA may form a gel before it is dissolved, especially at high temperatures, while the new material can be dissolved cleanly without gelation at a temperature> 35ºC.

Disposal and biodegradability

The new composite material is based on naturally occurring carbohydrates that quickly mineralize in the environment. The mineralization of this carbohydrate component may take hours or days. The biodegradation rate of the remaining components of the material is slower, but like PVA, based on the respiration treatment mineralization test, using the adaptive sludge in the wastewater treatment facility, they are ultimately considered biodegradable.

Link to this article: Degradable water-soluble 3D printing support material

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

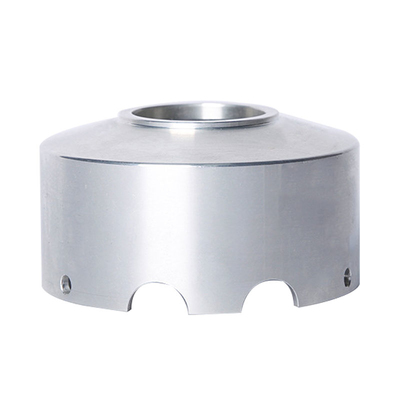

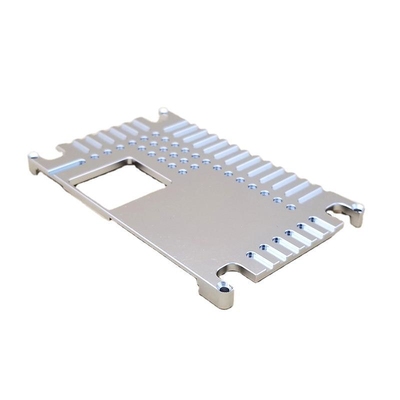

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material