Method for cutting 2D materials with high precision

Materials all have their own set of properties-for example, they can be insulating, semiconducting, metallic, transparent or flexible. Some combine several very useful properties, such as 2D materials. These materials consist of only one or a few layers of atoms, so they are very promising for the manufacture of next-generation electronic and optoelectronic devices.

"In our field, silicon is still king. But for some electronic devices, such as those that require flexibility or transparency, it has reached its limit. 2D materials may be a viable option." EPFL School of Engineering Microsystem Experiment Professor Jürgen Brugger, head of room 1, said.

Customize the properties of a specific application

Before using 2D materials, they need to be structured, which means cutting them to size and shape suitable for a given application. Whether in the entire material or in a specific location, its physical properties (such as the band gap) need to be adjusted.

Scientists at Microsystems Laboratory 1 worked with ETH Zurich and IBM to develop a new method to change the properties of these materials.

Deformation of materials with nano-tips

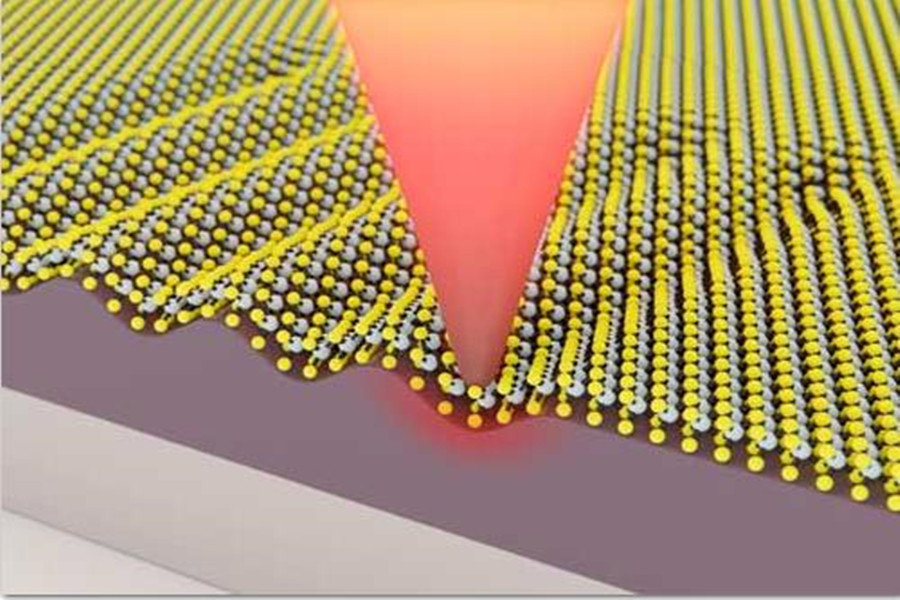

The research team used thermal scanning probe lithography (t-SPL), which requires placing a heated nanotip on the material and applying pressure to create the desired shape (in this case, wavy). At the same time carefully control force and temperature.

"There are already several methods that can deform 2D materials globally and locally. But our thermomechanical method will produce greater deformation, and therefore will produce greater changes in the physical properties of the material." EPFL laboratory scientist Ana Conde- Rubio said. More specifically, the new method can change the energy gap between the valence band and the conduction band, thereby changing the electronic and optical properties of the material. This change in the band gap can be performed locally with a spatial resolution as low as 20 nanometers.

The heated nanotip deforms the material to change its properties. Picture: Samuel Howell)

A single tool for cutting and modifying 2D materials

Scientists have developed a method for cutting 2D materials with high precision. Now, their goal is to combine this approach with new methods that change the properties of materials. "Using the same tool t-SPL, we will be able to manufacture devices with the required shape, size and physical characteristics, and the resolution can be as low as 10 nanometers." said Xia Liu, another scientist in the Brugger laboratory .

The team’s research results have been published in Nano Letters ("Thermomechanical Nano Strain of Two-Dimensional Materials").

Their work is part of a larger research project aimed at developing new processes for manufacturing and modifying polymer materials for wearable devices and implantable devices. The goal is to make the next generation of equipment transition from laboratory-scale production to industrial-scale production.

Link to this article: Method for cutting 2D materials with high precision

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( sales@pintejin.com ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material