Why do some alloys become stronger at room temperature?

An alloy is usually a metal to which at least one other element has been added. Physicist Adrian Lervik said that we already know that aluminum alloys can become stronger when stored at room temperature.

German metallurgist Alfred Wilm discovered this characteristic as early as 1906. But why is this so? So far, little is known about this phenomenon, but now Lervik and his colleagues from the Norwegian University of Science and Technology (NTNU) and Scandinavia’s largest independent research institution SINTEF have solved it. This problem is solved ("Atomic structure of solute clusters in Al – Zn – Mg alloys").

Lervik recently completed his PhD in Physics at NTNU. His work explains an important part of this mystery.

At the end of the 19th century, Wilm tried to increase the strength of aluminum, a light metal that had only recently emerged. He melted and cast many different alloys and tested various cooling rates common in steel production to achieve the best strength. Lervik said.

Will returned to the laboratory to continue tensile testing of an alloy composed of aluminum, copper and magnesium. He found that the strength of this alloy has increased significantly during the weekend.

During this time, this alloy is only kept at room temperature, but after a long time, it will not be able to complete the task.

Today, this phenomenon is called natural aging.

American metallurgist Paul Merica proposed in 1919 that this phenomenon is due to the formation of a kind of precipitation in the alloy by small particles of various elements. But there was no experimental method to prove this at the time.

Lervik said that until the end of the 1930s, X-ray diffraction methods could not prove that alloying elements aggregated into small clusters on the nanoscale.

Pure aluminum is composed of many crystals. A crystal can be regarded as a grid, and each square of the grid has an atom. Strength is measured by the resistance of the sheets to sliding against each other.

In an alloy, only a small part of the square is occupied by other elements, which makes it more difficult to slide between the sheets, thereby increasing the strength.

As Lervik explained, the aggregate is like a small drop of paint in a grid block. The alloying elements accumulate and occupy dozens of adjacent squares, which extend to several sheets. Together with aluminum, they form a pattern. These droplets have a different atomic structure from aluminum, making it more difficult for the flakes in the grid block to slip by dislocations.

The aggregation of alloying elements is called "clusters". In technical language, they are called the Ginier-Preston area (GP), named after the two scientists who first described them. In the 1960s, people first saw GP regions through an electron microscope, but they have not been seen at the single-atom level until now.

Practical application is the most important

In recent years, many scientists have explored the composition of aggregates, but little work has been done to understand their nuclear structure. Instead, many studies have focused on optimizing alloys by experimenting with age hardening at different temperatures and different times, Lervik said.

In an industrial environment, age hardening and the production of strong metal mixtures are obviously very important. However, few researchers and industry insiders care about what these star clusters actually consist of. They are too small to prove.

Lervik and his colleagues have different ideas.

Lervik said that through our experimental methods, we successfully used Trondheim's transmission electron microscope to take atomic-level photos of aggregates for the first time in 2018.

The research team also used the atom probe tomography instrument recently installed at NTNU to determine the chemical composition of the aggregates. The Norwegian Research Council's infrastructure project made this discovery possible. This investment has led to a new understanding of the fundamentals of metals.

Researchers studied alloys of aluminum, zinc, and magnesium, called 7xxx series aluminum alloys. These light metal alloys are becoming increasingly important in the automotive and aerospace industries.

We found clusters of particles with a radius of 1.9 nanometers in aluminum. Although they are numerous, they are difficult to observe under a microscope. We can only determine the atomic structure under special experimental conditions.

This is part of the reason why no one has done this before. The experiment is complicated and requires advanced modern experimental equipment.

We have experienced many times how tricky this is. Even if we succeeded in taking pictures of the star clusters and extracting some information about their composition, it took us several years to learn enough information to be able to describe the structure of the nucleus, Lervik said.

So what makes this work so special? In the past, people thought that aggregates were composed of alloying elements and perhaps more or less randomly arranged vacancies (empty squares).

Lervik said that we found that we can describe all the aggregates we observe in terms of a unique geometric spatial figure called a truncated cube octahedron.

In order to understand this discovery, we must first admit that aluminum crystals (square blocks) can be seen as a stack of cubes, each with 8 corners and 6 faces with atoms.

This structure is a side-centered cubic lattice of atoms. This geometric figure is like a cube, and a shell is formed by the surrounding cubes. We describe it as three shells surrounding the central cube: one is the side, one is the corner and the outermost layer. These shells are respectively composed of 6 zinc atoms, 8 magnesium atoms and 24 zinc atoms.

This figure further explains all the larger cluster units, which can be connected and expanded in three defined directions. This picture also explains the observations previously reported by others. These cluster units help increase strength during age hardening.

This is important for understanding heat treatment

These alloys will also undergo final heat treatment at higher temperatures (130-200°C) to form larger precipitates with a clear crystal structure. They hold the atomic plane (sheet) closer together and greatly strengthen it.

We believe that understanding the atomic structure of atomic clusters formed by natural aging is essential for further understanding of the precipitation formation process that determines the properties of so many materials. During the heat treatment, is the precipitation formed on the clusters or the clusters turn into precipitation? How to optimize and use it? Our further work will try to answer these questions, Lervik said.

Link to this article:Why do some alloys become stronger at room temperature?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

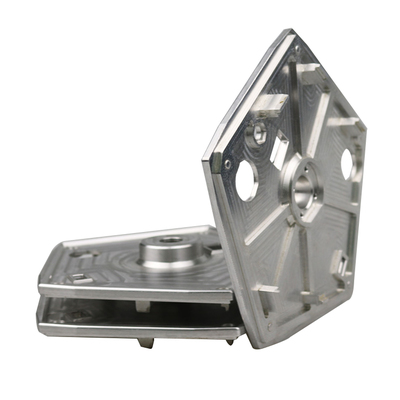

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

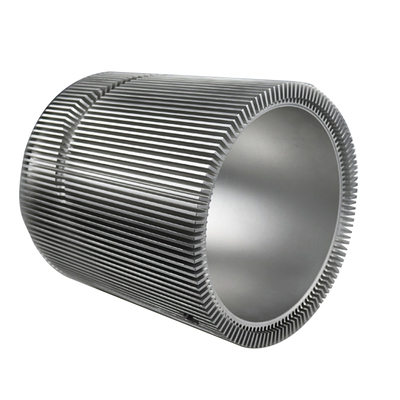

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material