Inventory of ten technological breakthroughs in the development of aluminum industry

Since last week, stimulated by the global energy crisis, commodity market base metal prices have generally risen. This week, Lun Aluminum hit a new high since July 2008, breaking through US$3,000 per ton for the first time in 13 years, leading the rise in other base metal prices.

According to industry insiders, aluminum is almost "solid electricity", and the production of each ton of aluminum requires 14 megawatt-hours of electricity, which is enough for an ordinary British household to use for more than three years.

Therefore, for industrial metals such as aluminum, which require large amounts of electricity to be smelted, investors bet that global energy costs will continue to rise, and their prices are naturally betted by investors.

Bloomberg quoted option market traders as saying that in recent weeks, investors have been buying aluminum call options with strike prices as high as $4,000 per ton. This is actually betting that aluminum prices may significantly exceed current levels and reach record highs.

Analysts said that this year's surge in aluminum prices usually prompts manufacturers in other places to reopen old factories and consider adding new supplies. But the greater increase in electricity costs is putting pressure on smelters and may make restarting difficult.

For example, a German smelter currently needs to pay about US$4,000 for the energy required to produce one ton of metal, far exceeding the current aluminum price.

We want to be grateful for all the inventions made by the predecessors of the aluminum industry at home and abroad in the development of the aluminum industry. These inventions are countless and it is difficult to cite one by one. In this article, only ten technological breakthroughs that have a fundamental impact on the world and China's aluminum industry are cited. Without these ten technological breakthroughs, the world and China's aluminum industry would not be able to achieve today's brilliant achievements.

1. Discovery and Utilization of Bauxite

Bauxite is the best raw material for the production of metallic aluminum, and its consumption accounts for more than 90% of the world's total bauxite output. Bauxite was first discovered by French geologists in 1821. To produce aluminum from bauxite, aluminum oxide is first produced, and then aluminum is produced by electrolysis. The mining of bauxite began in France in 1873, and the production of alumina from bauxite began in 1894, using the Bayer method. By 1900, countries such as France, Italy, and the United States had a small amount of bauxite mining, with an annual output of only 90,000 tons. With the development of modern industry, aluminum is used as a metal and alloy in the aviation and military industries, and then expanded to the civilian industry. Since then, the aluminum industry has developed rapidly. By 2016, the world's electrolytic aluminum production has reached more than 57 million tons. , The bauxite mined in 2016 increased to 262 million tons. According to 2017 data from the U.S. Bureau of Mines, the world's bauxite reserves are 28 billion tons. The bauxite resources given to humans by the earth provide raw materials for the world and China's aluminum industry.

2, the Bayer process produces alumina

The Bayer process is a widely used method of producing alumina from bauxite in industry. It was invented by the Austrian engineer Bayer in 1887. At present, 95% of the world's alumina companies use the Bayer process to produce alumina.

3. Production of electrolytic aluminum by Hall-Elu method

In 1886, American Hall and Frenchman Elu independently invented cryolite-alumina molten salt electrolysis to produce aluminum. So far, all aluminum in the world is produced by electrolysis.

4, aluminum alloy smelting

Smelting is a method of alloying metals. It uses heating to change the state of the metal, so that the base metal and alloying components are melted into a uniform composition according to the required ratio, and it can meet the internal purity, casting temperature and other specific requirements. crafting process. The quality of the melt has a decisive influence on the processing performance and final use performance of the aluminum. If the quality of the melt is congenital insufficient, it will bring potential dangers to the use of the product. Therefore, the smelting plays a dominant role in the quality of the processed product. A key process.

5. Aluminum melt processing technology

Inclusions and hydrogen content in the metal have significant adverse effects on the strength, fatigue resistance, corrosion resistance, stress corrosion cracking performance and processing performance of the material. Effectively controlling the hydrogen content of the melt and the content of oxidized inclusions to improve the quality of cast rods and rolled plates has become a common goal pursued by the metallurgical, casting and material industries of all countries. At present, electromagnetic stirring, refining in the furnace, on-line deterioration outside the furnace, on-line degassing, and on-line filtration are widely used to reduce the hydrogen content and inclusion content in the aluminum alloy melt, and improve the mechanical properties and appearance quality of the ingot.

6. Direct water-cooled ingot casting

Alcoa invented the direct water-cooled casting technology, which was adopted by all Alcoa factories in the 1930s. In the 1950s, direct water-cooled ingots could be used to manufacture large products required by the aerospace, marine and transportation industries. With the advancement of direct water-cooled casting technology and equipment, the size of the ingot is increasing. The current slab can weigh up to 45 tons, and the diameter of the aluminum rod for extrusion can reach 1.2 meters.

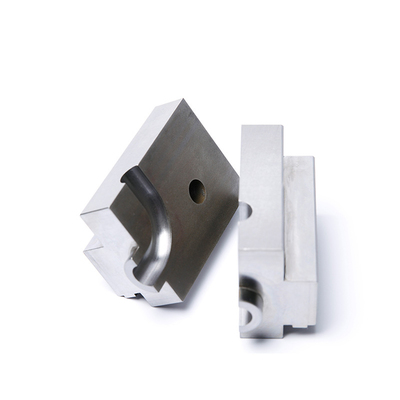

7, aluminum processing and die casting

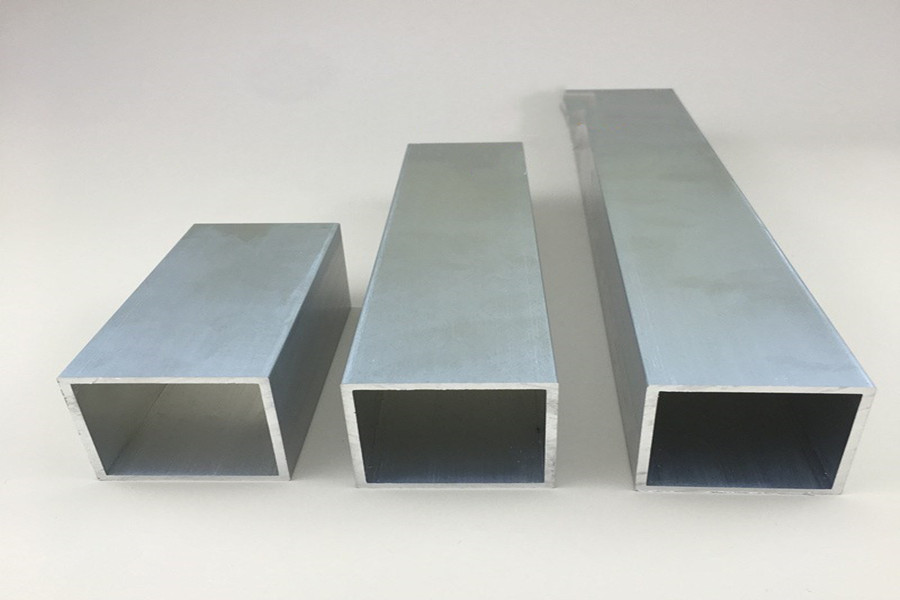

Aluminum processing is to process aluminum billets into materials by plastic processing methods. The main methods include rolling, extrusion, stretching and forging.

Among the aluminum and aluminum alloy processed materials, rolled materials (plates, strips, strips, foils) and extruded materials (tubes, rods, shapes, wires) are the most widely used and have the largest output. According to statistics, the annual output of these two types of materials They account for about 58% and 39% of the world's total annual aluminum output (average). The remaining aluminum processed materials, such as forged products, account for only a few percent of the total aluminum output.

Die casting is abbreviated as die casting, which is a casting method in which molten alloy liquid is poured into a press chamber, the cavity of a steel mold is filled at high speed, and the alloy liquid is solidified under pressure to form a casting. Die-casting machine, die-casting alloy and die-casting mold are the three major elements of die-casting production, and none of them are indispensable. The so-called die-casting process is the organic and comprehensive application of these three elements to enable stable, rhythmic and efficient production of qualified castings with good appearance, good internal quality, and dimensions that meet the requirements of the drawing or agreement.

8. Heat-treatable and strengthened aluminum alloy

German scientists discovered the aging strengthening of aluminum-copper-magnesium alloys in 1908, which greatly improved the strength of aluminum alloys and expanded the application areas of aluminum alloys.

New alloys are constantly being developed in various countries. At present, the number of wrought aluminum alloys registered in the Alcoa Association has reached 680, of which the most used is the 6063 aluminum-magnesium-silicon series registered by Alcoa in 1954. Aluminum alloy.

9, aluminum surface treatment technology

In the past sixty years, the surface treatment technology of aluminum products has developed extremely rapidly, and the aluminum alloy products after surface treatment give people a very beautiful and delicate appearance. Chemical conversion coating treatment is our most common surface treatment technology. Such as anodic oxidation, composite anodic oxidation, micro-arc oxidation, electrophoretic coating treatment, etc. are all chemical conversion coating treatments. Chemical conversion coating treatment is more mature and stable than other surface technology treatments. However, it is more of a composite technology that is used now, and composite technology is to gather the advantages of various technologies and avoid their disadvantages. For example, arc glow technology, ion beam combined sputtering technology, etc., ion beam combined sputtering technology combines magnetron sputtering with ion implantation, and ion sputtering combines the advantages of high speed, low temperature, and good binding force. Combine laser and sputtering, etc.

10. Environmental protection technology in the aluminum industry

The main pollutants in the aluminum industry include red mud produced in the alumina production process, fluorine-containing waste gas from electrolysis production, carbon calcination and roasting flue gas, electrolytic cell overhaul waste, aluminum processing wastewater, waste oil and other industrial wastes. , Exhaust gas and wastewater have always been the key targets of environmental protection monitoring, which are related to occupational health and safety and the sustainable development of society, ecology and economy.

In order to make the aluminum industry continue to develop in the direction of green and low-carbon, corresponding environmental protection and energy-saving equipment is constantly being developed, and strive to improve the overall environmental protection level of the aluminum industry in terms of environmental protection, intelligence, and integrated control.

Link to this article: Inventory of ten technological breakthroughs in the development of aluminum industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material