What are the ways to machining plastic prototype model?

Machining Plastic Prototype Model

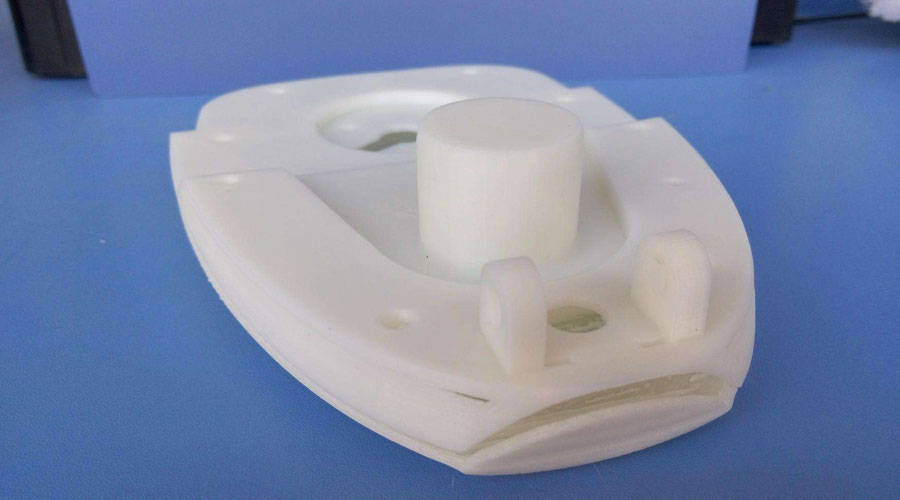

| Prototype machining can reflect the designer's creativity very well. Such as the structure, the appearance of the Prototype, etc., the Prototype model allows the time to market the parts is greatly shortened, its manufacturing is forward-looking, before the mold can be developed, you can use the sample for the mall to promote, take the lead, and in the early sale, Prepare for production and occupy the market early. |

The first step:

according to the customer to provide 3D data analysis to determine the processing technology, to determine the processing technology for CNC processing;The second step: data processing:

- 1) According to the characteristics of the plastic model processing technology, there are two types: one is data that can be directly processed; the other is the need to use CAD software, proe software or ug software to split into processable data;

- 2) There are two kinds of processing schemes. One is to do auxiliary surface processing in the data. When programming, draw a traction surface around the plastic model with a radius of about 1 mm or more to divide the A or B processing surface, which will raise the surface. 0.5-0.8 mm is used to fix the connection between the plastic model and the blank, and then all the processing is completed and then milled off. This solution uses a flat knife or a ball-end knife to open the thick; the other is to do the auxiliary surface processing. This plastic model is adopted. Ball head knife processing;

- 3) After the data is processed to the state of direct processing, it is necessary to use computer-aided processing software for programming;

- 4) The two softwares that are programmed are Mastercam 9.1 and WorkNC 16.21, which are used to typeset and write 2D programs; the WorkNC 16.21 is used to calculate complex surfaces; the Mastercam 9.1 software is used for typesetting and writing 2D programs. Or the preparation of 3D machining program, also use the "contour shape" command in Mastercam9.1 software to generate the boundary line of the machining, and use this line to generate the plane as the boundary range auxiliary surface in WorkNC 16.21 software;

- 5) Program for auxiliary surface when programming: Use Mastercam9.1 software to do the auxiliary surface transfer IGES format with WorkNC 16.21 software for programming. This solution should be consistent with A or B surface roughing tools;

- 6) Do not plan the auxiliary surface when programming: Use the Mastercam9.1 software to write the flat knife open rough path, the equation of the boundary range: tool radius + open reserve + 0.15 mm; no auxiliary surface is transferred out of the IGES format around the data. It is programmed with WorkNC 16.21 software; at this time, the B-side roughing tool is smaller than the A-side roughing tool, or the No. 1 or No. 2, so as to avoid the A-side being used as a fixed PVC rod to be milled and the plastic model is scrapped off;

- 7) Programming and writing out the process flow to the operator department, and transferring the program to the machine for machining;

The third step: CNC machining

- 1) After the machine department receives the work order, it analyzes it. After the analysis is completed, the machine and personnel are arranged, and the material is marked according to the work order.

- 2) The fixing method of the machine adopts woodworking glue glue or AB glue, and is reinforced with small ABS block or PVC rod around the blank. The positioning method adopts the positioning pin method, and the positioning pin is positioned with the finished ABS rod of 6.0 or 8.0 mm;

- 3) Plastic models that require both sides of A and B:Side A:The A surface is processed by cutting fluid + compressed air cooling, and the programming is done as an auxiliary surface. After the A surface processing is completed, the area of the plastic mold structure needs to be bonded with the hot melt adhesive to strengthen the ABS block, which is higher than the front end of the blank A side. Milling, so that it can play a good supporting role when processing the B-face, reduce the vibration generated by the machining. If the auxiliary surface is not used, the PVC rod should be bonded with hot-melt glue around to fix the plastic model and the blank. After the completion of the A-face processing, the hollowed out part is filled with gypsum to prevent vibration when the B-face is processed;Side B:The B surface is positioned by the positioning pin, the bottom is sealed with waterproof double-sided tape and surrounded by woodworking glue; when it is processed, it is cooled by compressed air; after the B surface is finished, it needs to be operated by the captain and the programmer to confirm that there is no problem and then the machine can be dismissed;

- 4) The two faces of the plastic model cannot be completely processed in place, and it is necessary to chase the machining. It is necessary to design the auxiliary jig and then finish the machining on the machine;

- 5) As long as the plastic model is processed by one surface, the bottom of the blank is processed flat and the waterproof double-sided tape is applied to complete the processing;

- 6) For some mass production parts, it needs to be modified, and the modification work is completed by designing auxiliary fixtures;

- 7) In order to prevent deformation during the processing of the plastic model, it is necessary to bake in the oven in advance to release the deformation stress: ABS material, it needs to be baked at 80 degrees for 4 hours, and the oven door is not cooled naturally in the oven; PC material: need 100 degree baking Bake for 6 hours, do not open the oven door to cool naturally in the oven; POM material: need to bake for 8 hours for 8 hours, do not open the oven door to cool naturally in the oven;

The fourth step: post machining

After the treatment, you need to get the semi-finished product after the NC is off, then clean the plaster with water, then remove the hot melt glue with alcohol, remove the oil stains and other debris with the oil, and dry the oven for 45 minutes and 20 minutes to check the quantity and size. Shape and material, after confirming the error, remove the burrs and remove the dead corners, and splicing with glue or dichloromethane adhesive;

The surface treatment of the post-processing department is as follows:

- 1) The sandpaper is manually polished, and the sandpaper is cut into a sandpaper strip of about 150*40 mm width, and sanded with a similarly similar silicone pressure plate, the order is from coarse to fine;

- 2) Polishing, transparent PMMA needs to be sanded from coarse to fine to 2000# sandpaper, then polished with 3M polishing wax and polishing cloth or polishing machine;

- 3) Dyeing, parts that need to be dyed After polishing, pour the dye into a stainless steel iron drum and heat it to 60-80 degrees, then put the parts into the soak for 5-10 minutes to take out, dyeing can be completed;

- 4) After spraying, after the plastic model is bonded, polish it to the No. 320 sandpaper spray primer, and then sand it to 800 sandpaper or 1000 sandpaper to spray paint;

- 5) Electroplating, electroplating is aluminized and chrome-plated. The process of aluminizing is vacuum plating. It needs to be sprayed to 600# sandpaper. The chrome plating process is water plating. It needs to be polished to 2000 sandpaper and then polished for electroplating. The aluminum-plated parts can be detached and spliced, and the chrome-plated process can not be detached and spliced, and can only be processed as a whole;

- 6) Transparent and transparent. This method is used for direct polishing. The PC parts are also polished to 1000 grit sandpaper and then brightened with dichloromethane.

The fifth step: silicone mold machining

Make a prototype using CNC and use this prototype to make a silicone mold.

Link to this article: What are the ways to machining plastic prototype model?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material