How to combine 3D printing with CNC machining?

2019-10-19

|

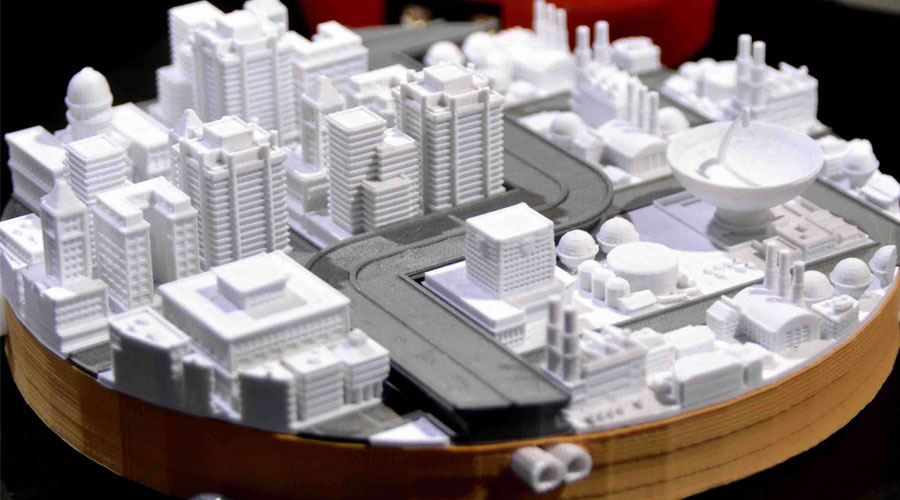

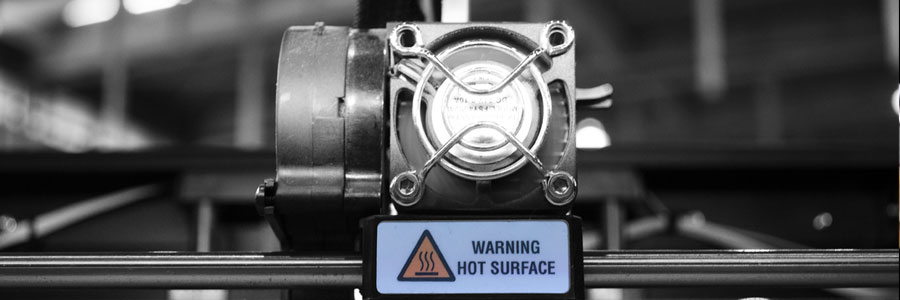

3D printing has changed the way companies think about prototyping. With the power of additive manufacturing, turning digital 3D design into physical objects is easier than ever. The startup cost is low, the learning curve is short, and the results are often consistent and satisfactory. But not everything can be printed in 3D. Certain shapes and materials are still more suitable for other manufacturing processes, such as CNC machining or injection molding, and many commercial 3D printers simply cannot produce parts with the tolerances required for practical applications. |

What are the different of 3D printing and CNC machining?

|

Performance |

Cnc Machining | 3D Printing |

|

Material |

Mainly processed metal, can also be used to process cork and hardwood, thermoplastics, acrylics, modeling foams and waxes, etc. | Metal, ceramic, wax, sand and composites |

|

Speed |

Quantity machines can remove material reworked parts faster than 3D printers. However, a large amount of process planning and setup is required, especially when multiple processing steps are required, the parts often need to be repositioned. | One molding can be achieved, which means that it does not depend on other manufacturing stages other than post processing. Batch manufacturing (such as SLS and SLM) is possible for many processes. |

|

The Complexity |

The accuracy is determined by the geometry of the tool, as all tools are rotating and have a radius of the tooling angle. Shape features smaller than the tool size can be produced, such as thin walls that are smaller than the diameter of the tool. CNC machined surface is better than 3D printed surface quality | Small feature sizes are typically controlled by the diameter of a material delivery mechanism (eg, a nozzle for FDM or a nozzle for material ejection) or a spot of a machine (eg, a sintered laser or UV source). FDM print layer thickness is 100-200 microns, material jet printers can be as low as 16 microns resolution |

|

Geometric Shape |

The CNC machine relies on a point-to-point machining process that predetermines the tool path to remove material. Therefore, the surface that the CNC machine can reach is limited and does not require adjustment of the part. Can be used to machine very large and very small parts | Model suspension surface needs to add support, which increases printing cost and time |

|

Process |

Operators or engineers are required to consider tool selection, spindle speed, proximity, angle, and cutting path. These factors have greatly affected the quality and construction time of the components. | Once the model has been uploaded and the orientation, layer thickness and support position are selected, most AM machines can print complete parts without any manual intervention. |

For some projects, the answer is not in additive manufacturing or traditional processing, but in between. Combining these two processes is easier than you think, and it offers a big advantage.

So when should you perform CNC machining on your 3D printing parts, what should you do?

▶ When should machining 3D printed parts for your new projects?

Although 3D printing and CNC machining are generally considered to be diametrically opposed processes, they can actually be combined to produce good results. The part is first 3D printed and then the part is CNC machined to reduce or modify certain areas.

Although 3D printing and CNC machining are generally considered to be diametrically opposed processes, they can actually be combined to produce good results. The part is first 3D printed and then the part is CNC machined to reduce or modify certain areas.-

1. Time Urgent: When alternatives (usually injection molding or similar) require too much time, companies should consider CNC machining their 3D printed parts. While the sequential process of 3D printing and CNC machining involves multiple steps, the combined approach is generally faster than creating and utilizing a mold processing tool.

The combination of 3D printing and CNC machining also allows for mobile adjustment of the product or prototype, as modifying digital files is easier than modifying the injection tool. -

2. Accuracy is key: the accuracy of 3D printers has increased year by year, but many industries require critical end-use components to have tolerances that are currently not achievable on 3D printers.

By combining 3D printing and CNC machining, the required precision can be achieved while still taking advantage of 3D printing, including low cost and complex internal geometry. High-end 3D printers typically achieve tolerances of ±0.005 inches, while CNC machines can compress them to ±0.002.

▶ Things to consider when processing 3D printed parts

The process of combining 3D printing and CNC machining requires two hands-on expertise and some steps can be taken to ensure smooth manufacturing.

The process of combining 3D printing and CNC machining requires two hands-on expertise and some steps can be taken to ensure smooth manufacturing.-

1. Note: In order to get the best results when machining 3D printed parts at CNC, it is important to specify exactly what you need to do. This should include specifying which areas require strict tolerances and allowing the mechanic to work properly. When these tolerances are specified, the mechanic may suggest some design adjustments to the 3D printed parts to make the job easier.

- 2. Measure: These recommendations may include instructions for using excess material. Since CNC machining will effectively reduce the quality of the part by cutting out some parts, additional material may need to be printed to make these adjustments. If the number of layers is insufficient, the machining process may not produce the correct size.

- Positioning: The areas of the 3D printed parts that need to be machined should be properly positioned so that the tool can reach them.

Link to this article: How to combine 3D printing with CNC machining?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Our Services

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

Case Studies

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

Material List

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material

Parts Gallery