3D printer purchase, use precautions and daily maintenance

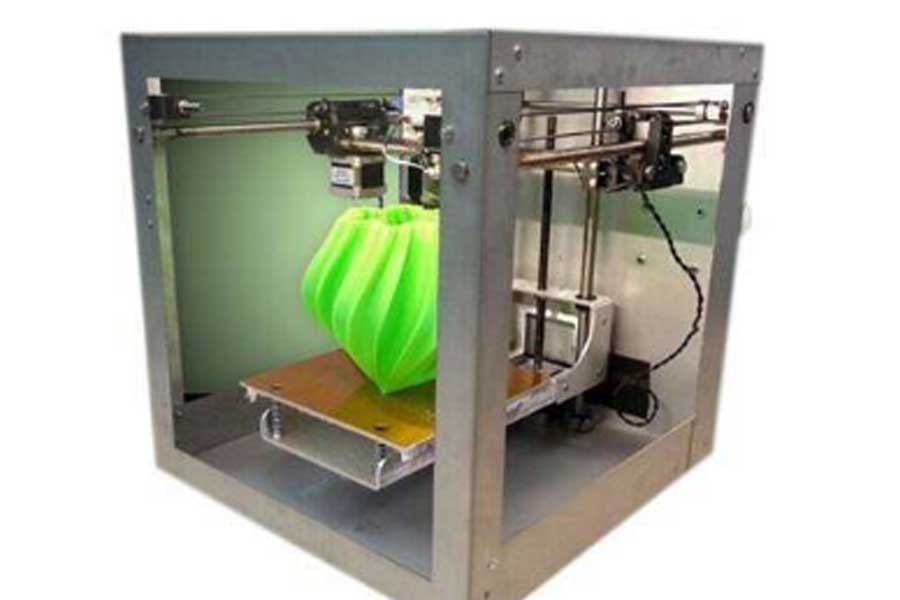

A 3D printer is a kind of rapid prototyping technology. It is based on a digital model file, using powdered metal or plastic and other bondable materials to construct objects by layer-by-layer printing.

Precautions for purchasing 3D printers:

The first is to check the safety of the 3D printer. Safety is the first important indicator of the equipment. As many 3D printer companies now produce 3D printers that are purely handmade, coupled with backward technology, a large area of high temperature on the bottom plate is required. Heating, high-power high temperature can easily cause safety hazards such as loose belts, printing inaccuracy and line aging. The 3D printer is a precision equipment that needs to work stably for a long time. Stability is the basic requirement of this type of equipment. It can print for 50 hours without interruption at full load. All parts of the machine work normally without loosening or shaking, and the accuracy remains unchanged. qualified.

Third, check the power of the 3D printer and the printable consumables of the 3D printer. The power is directly related to the service life and stability of the device. Check the printable consumables of the 3D printer. Whether the printing consumables of the 3D printer are abundant and whether the technology is mature, like Some 3d printers themselves can use many kinds of materials: such as: ABS\PLA\PC\soft polyester\chocolate\wax\water-soluble materials and so on. When consumers buy a 3D printer, they must choose carefully and choose a 3D printer that is widely used with 3D printing consumables.

Finally, the basic quality verification method selected by the 3D printer. The case must be kept in a closed state during the working process. The machine must be kept in a closed state for more than 50 hours for aging before the machine is lifted. The appearance of the case is basically the same as the room temperature during the printing process. , No peculiar smell wafting out, and after the printed workpiece is fine and ideal, check the loosening and aging phenomenon, and the machine can be lifted if there is no problem.

Precautions for the use of 3D printers:

1. When you print a new thing, you can use the printer's lowest settings (ie high speed, low precision) to quickly experiment first. Because you definitely don't want to spend n hours to find out the size of the item or what is wrong after the printing is completed!

2. If you use ABS plastic to print, make sure to preheat your printing platform to its maximum temperature, because the higher the temperature, the more it can prevent the ABS material from curling up during the printing process.

3. If you are printing with PLA plastic, you can stick a layer of blue painter's cloth tape on your platform without heating the printing platform. It is cheaper and easier to use than the legendary tape.

4. For a heated printing platform, Kapton tape is the most suitable because it has better heat resistance and heat dissipation than blue painter's tape cloth tape.

5. Learn more about the properties of the printing materials you choose. The two mainstream plastics used in personal 3D printing are ABS and PLA. Each has its own characteristics, such as melting temperature and discharge speed. Make sure that the data of the printer you set can support the printing materials you use.

Daily maintenance of 3D printer:

First of all, before turning on the 3D printer every day to print, do some necessary checks: whether the nozzle is blocked or damaged, whether the connecting wires of each part are normal, whether the motor bearings and guide rails are short of oil, whether the platform is calibrated, etc. If there is stagnant in the nozzle, clean it up immediately, replace the damaged or aging parts in time, add lubricating oil to the moving parts regularly, and tighten the nut if it is loose.

Secondly, during the printing process of the 3D printer, each parameter setting should not exceed the limit of the equipment, otherwise it will not be able to print qualified products, and problems such as excessive temperature or excessive load will also damage the equipment. There is also something wrong in the printing process. If necessary, stop the machine for processing. Don't let the equipment continue to work because of the worry of stopping the machine and reprinting.

Finally, do a good job of cleaning after the printing is completed. The dirt on the nozzle, platform, guide rail, motor, fan, etc. of the 3D printer should be cleaned up. Do not accumulate for a long time and make it difficult to clean up.

Link to this article: 3D printer purchase, use precautions and daily maintenance

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material