China Terminal Molds Lead The Terminal Blocks Development

In recent years, the domestic terminal mold industry, as a member of the mold industry, has many products sold globally, but profits have been hovering at a low level. The most infuriating and even helpless thing is that many products have no difference in quality compared with similar foreign products, but the unit price is much higher than that of domestic terminal mold products, making it difficult for many domestic products to enter some high-end markets. . Faced with such a phenomenon, this has to cause practitioners in the domestic terminal mold industry to think about some problems.

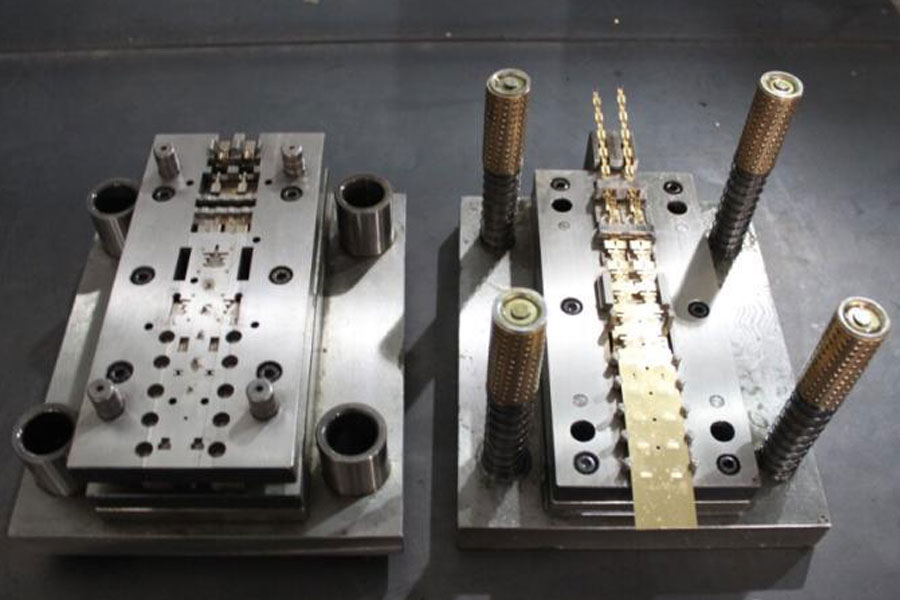

The manufacturing of terminal molds affects the quality of the terminals, especially in the critical position of the terminals. With the development of regional intelligence and precision in China's domestic mold industry, it has also improved the manufacturing level of my country's terminal industry to a certain extent.

In order to comply with the increasing competition in the market, my country’s industry is experiencing important changes in recent years, such as the transformation of molds to market-based or customer-requested flexible consumption; mold design is independent to the integration of design and integration; consumption in a certain place to global purchase And consumption changes; manufacturing plants’ requirements for quality and safety are also improving from time to time. These changes are advancing and entering a new stage of application, namely the intelligent deployment stage. It also drives the terminal manufacturing industry to intelligent and automated production technology from time to time.

Although the total amount of smart molds is not much at present, PCB terminal blocks represent a new development direction of mold technology, and play an increasingly important role in the adjustment and deployment of product structure in the industry. Once the smart mold is deployed, it will inevitably play a powerful role in promoting the entire mold industry. Therefore, it is especially necessary to give priority to the deployment of smart molds in the development of the industry. It is imperative that the terminal industry adopts higher-end molds. In order to ensure the quality and reliability of the wiring terminals and prevent the occurrence of the above-mentioned fatal shortcomings, it is recommended to discuss and formulate the corresponding selection technology requirements according to the technical conditions of the product, and carry out the following targeted reliability tests to prevent failure. At present, there is no such item in the acceptance test of ordinary terminal consumer manufacturers, and users generally need to stop the continuity test after installing the machine.

Therefore, it is recommended that consumer manufacturers should increase some key models of products. Some terminal blocks are used in dynamic vibration environment. The actual test proves that only the static contact resistance is qualified, and it cannot guarantee the reliability of the contact in the dynamic environment.

Since the connectors with qualified contact resistance often show instantaneous energization when they stop vibration, impact and other simulated environmental experiments, for some high-reliability terminals, the dynamic vibration experiment is used to assess their contact reliability. The single-hole separation force refers to the separation force of the contact member in the inserted state from being stationary to moving, which is used to characterize the contact between the pin and the socket.

Link to this article :China Terminal Molds Lead The Terminal Blocks Development

Sheet metal, Copper Milling, carbon steel,online laser cutting service, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, Copper Milling, carbon steel,online laser cutting service, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material