Plastic Molds Account For Up To 30% Of The Entire Mold Market

Relevant data show that the plastic mold market currently accounts for about 30% of the entire mold industry, and the proportion of mold imports and exports is as high as 50 to 70%. With the rapid development of China's machinery, automobiles, home appliances, electronic information, and building materials and other pillar industries of the national economy, this proportion will continue to increase.

Experts predict that the overall trend of the mold market is steady and upward. In the future mold market, the development speed of plastic molds will be higher than that of other molds, and the proportion in the mold industry will gradually increase.

Although plastic molds have become the most attractive cheese nowadays, cherries are delicious and difficult to plant. Due to the complex shape and flexible design of plastic parts, it has high requirements for mold materials, design level and processing equipment, and not everyone can easily get involved.

Experts believe that there is still a big gap between China and foreign countries, and the three major bottlenecks that restrict the development of the mold industry must be broken as soon as possible: one is to increase the research and development of plastic materials and injection molding technology; the other is that plastic mold companies should apply to the park Development and accelerating the integration of resources; third, the tooling level such as mold test results inspection must be kept up as soon as possible, otherwise the development of the plastic mold market will be restricted.

The plastics industry is one of the pillar industries of my country's economy. Plastic hardware has become a new economic growth point for the plastics industry, especially for plastic molds. The market prospects are broad, but there are still shortcomings, and the technology needs further innovation.

As one of the pillar industries of my country's light industry, the plastics industry has maintained a growth rate of more than 10% in recent years. In the plastic industry, the plastic hardware industry market is very active, becoming a new consumption hotspot and a new economic growth point. The plastic mold market has a considerable prospect, but it is far from the foreign technology level.

At present, my country's molds need to break through the bottleneck restricting the development of the mold industry. Because with the rapid development of China's pillar industries such as machinery, automobiles, home appliances, and building materials, plastic molds account for about 30% of the entire mold industry. However, due to the complex shapes of plastic mold parts, there are higher requirements for their design level. Therefore, the technical level of mold trial results inspection must be innovative to keep up with the development trend of the times, otherwise the development of plastic molds will be restricted.

The industry believes that mold manufacturing companies must improve their own technology if they want to break through the bottleneck. At the meeting of the State Council on the 26th, the Premier also stated that today's technological revolution plays an extremely critical role in economic development and promotion of economic upgrading. Advocating mass entrepreneurship and innovation also uses innovative means to promote entrepreneurship.

Although the growth rate of mold exports has been greater than that of imports in recent years, the absolute amount of increase is still that imports are greater than exports, which has caused the mold foreign trade deficit to increase year by year. This situation has improved in 2006, and the deficit has decreased slightly. There are two main reasons for the increase in the foreign trade deficit of molds: First, the sustained and rapid development of the national economy, especially the rapid development of the automobile industry, has brought a strong demand for molds. Some high-end molds cannot be produced in China, so they have to be imported; but there are some. Molds can be produced domestically and are also imported. This is related to China's current tariff policy and project approval system. The second is insufficient encouragement for mold exports. Now molds, like other electromechanical products, have an export tax rebate rate of only 13%, but not 17%.

With the rapid development of China's plastics industry, especially engineering plastics, it is foreseeable that the development speed of China's plastic mold industry will continue to be higher than the overall development speed of the mold industry, and the annual growth rate will remain at about 20% in the next few years.

Link to this article:Plastic Molds Account For Up To 30% Of The Entire Mold Market

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

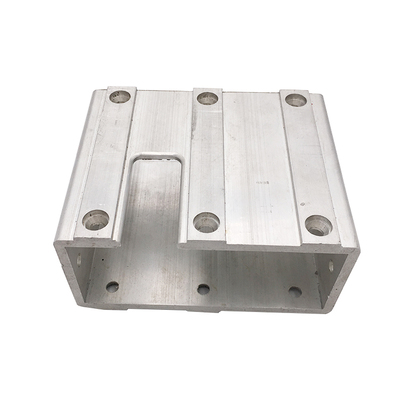

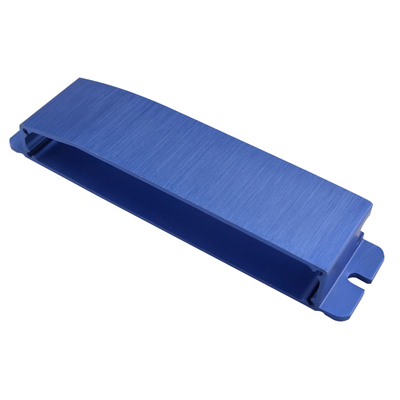

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material