Chinese aerospace companies are using 3D printing for missile component manufacturing

Aerospace Haiying (Harbin) Titanium Industry Co., Ltd., affiliated to the Third Research Institute of China Aerospace Science and Industry Corporation, has developed its main business into one of the top ten industries in Heilongjiang Province in only 3 years. All of this is inseparable from the company’s deputy General Manager Liu Zhenjun and his hard-working team.

Liu Zhenjun, who graduated from Beijing Institute of Aeronautical Materials, is a well-known casting technology expert in China. In 2013, Aerospace Haiying (Harbin) Titanium Industry Co., Ltd. was established to construct the first-phase construction project of the Titanium Industrial Park and to industrialize the results of the titanium alloy special process project for aerospace and aviation. His scientific and technological team has achieved remarkable results in the field of aerospace titanium alloy materials and forming manufacturing and won the second prize of National Defense Science and Technology Progress Award.

The titanium alloy 3D printing team walked into the production workshop, and every step of production was carried out in an orderly manner. The employees of the precision casting center completed each of the most basic tasks attentively and perfected the details of each production.

In the process of 3D printing technology for the flying missile rudder blades, the technicians encountered the technical problem that the product deformation occurred during the processing process and the processing failed. In order to overcome the problem, Chen Zhuo, the technical team leader, believes that the process, equipment and raw materials must be thoroughly investigated to find the source of the problem. The process corresponds to the preparation of the processing program. Chen Zhuo and all the technicians have conducted repeated demonstrations and calculations. Sometimes the calculation and discussion of a process parameter is an overnight.

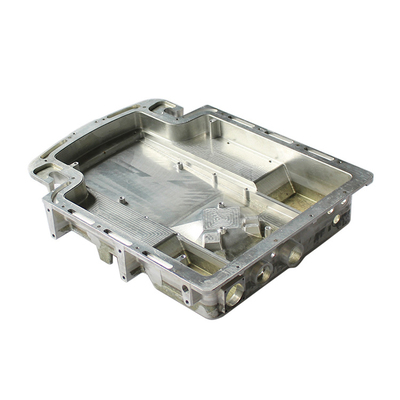

3D printing products-lightweight structural parts Metal 3D printing technology has greatly shortened the product manufacturing cycle. This advantage in turn enables designers to integrate multiple parts during product design, which greatly simplifies product design. After more than a year of technology research and development and production practice, the company's main business income reached 102.9 million yuan in 2015, with a total profit of 5.64 million yuan and taxation of 4.61 million yuan.

“Now is the best time for technological innovation and achievement transformation in Heilongjiang Province. During the construction of the project, provincial and municipal leaders have visited the company many times for investigation and guidance. In view of the practical problems in the construction of the project, such as infrastructure construction and power transformation construction, they have been given Quickly coordinate and solve.” Liu Zhenjun said that the company will start the second phase of the industrialization project of the titanium industrial park, expand the existing industrialization, and strive to develop titanium alloy additive manufacturing, high-end powder preparation, and 3D printing equipment development. Industrial direction such as production.

Link to this article:Chinese aerospace companies are using 3D printing for missile component manufacturing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision China CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces(Die Casting Service). Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision China CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces(Die Casting Service). Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material