What do metal manufacturers need to pay attention to when producing alloys?

The metal manufacturer selects the metal to perform the function according to the physical characteristics of the metal: the stainless steel exhaust pipe should be rust-proof; the heat exchanger in the nozzle must be under harsh conditions of use.

Obviously, the way the metal behaves is critical to function. In these examples, due to differences in their applications, specific alloys will be selected. Metal manufacturers must understand the behavior of stainless steel in order to successfully produce stainless steel products for industrial use.

Ductility defines deformation

Ductility is one of the most important metal properties to be considered by manufacturers. Ductility is the ability to make a material plastic without breaking.

The historical process of forging involves hammering metal into various forms. Shapes such as blades are relatively simple to manufacture because no complicated bending is required. However, the hammered blade and shape are disposable. In a sense, each work is a unique artwork. Nowadays, metal formers must repeatedly produce stainless steel parts that meet specifications. Unlike forging, there are fewer opportunities for immediate corrections.

Understanding its malleability is essential to success. The manufacturer must be based on its mechanical properties of the alloy so that the final form meets the required physical properties.

Metal manufacturers can gain insight into the ductility of alloys by observing characteristics such as material elongation (as indicated by the material certification), common applications, and work hardening rate. But ductility occurs at the atomic level. Therefore, it is important to look at the atomic level to fully understand what ductility is and its importance to the process.

Atomic behavior determines the behavior of metals

Metals behave differently from other materials. They have the ability to plastically deform, maintain shape and maintain deformation strength. These unique characteristics are derived from the types of atoms in the metal and their bonds. Atomic bonds essentially determine how electrons are transferred or shared between atoms in the material. Bonds keep atoms together as coherent materials.

When electrons are freely shared between atoms, the metal atom and the metal bond remain together. Atoms are arranged in 3D, called an ordered lattice.

Metal bonds allow atoms to move through the lattice. It is this atomic motion that defines the plastic deformation capacity.

Deformation may occur under compressive or tensile stress. These stress types define all manufacturing processes.

Compared with misaligned grain boundaries, metal atoms pass through the grain mass more easily. Imagine that when driving on a highway, all the ramps are suddenly 10 feet higher than the highway. To enter the downhill, the driver must drive the car up 10 feet.

The movement of metal atoms in the compressed state is called ductility, and in terms of tension and ductility, it is called “ductility”. Both terms are defined under plasticity, which means the ability of a material to deform without breaking.

Imprinting is a compression manufacturing process that relies on ductility. Deep drawing is a drawing process that relies on ductility.

In these two processes, atoms move through different methods, but both require atomic movement to function. Consider trying to cast porcelain dinner plates. Porcelain is a ceramic that contains covalent bonds instead of metal bonds. Unlike metal bonds, covalent bonds cannot freely share electrons, so they can prevent atom movement. Under pressure, due to the lack of atomic motion, the plate will shatter; it will not deform plastically. Therefore, metal is the best material for imprinting operations.

Grain and dislocation factors

Metal atoms solidify into a crystal sequence during the annealing process, just like ice crystals grow on a cold surface. Atoms nucleate at a certain point and grow outward as more atoms gather. The growth part eventually meets the nearby growth nucleation point. The interfaces where these assembled atoms are not aligned with each other are called grain boundaries.

Related groups of atoms in different arrangements are called crystal grains. Compared with misaligned grain boundaries, metal atoms pass through the grain mass more easily. Imagine that when driving on a highway, all the ramps are suddenly 10 feet higher than the highway. To enter the ramp, the driver must climb the car 10 feet. Both highways and ramps may be easy to drive, but getting to a misplaced ramp from the highway will be more difficult, requiring more energy and different conditions.

The crystal grains in the crystal lattice themselves contain orientation defects, called dislocations. Dislocations can occur during recrystallization, but are mainly produced by cold working. If enough stress is applied, certain types of dislocations will move. Therefore, the movement of the dislocation is the movement of misalignment. The atoms will slide from one side of the dislocation to the other, causing significant dislocation movement.

The dislocation itself can also collide from this movement. Just like traffic jams, the accumulation of dislocations will prevent further movement of dislocations.

Ductility is a measure of the effective plastic deformation caused by the movement of atoms. Restriction of movement limits ductility; therefore, the accumulation of dislocations can lead to reduced ductility. In addition, accumulation requires more force to move atoms. This effect is called work hardening.

The applied stress that causes the metal atoms to move permanently in the crystal lattice is the yield strength. The accumulation results in a higher yield strength because more force is required to move the atoms. Therefore, tempered metals have higher tensile strength, yield strength and hardness.

As the cold working elongation decreases. This is important because elongation is a measure of the ductility of a material. More specifically, it is a measure of the total plastic deformation that a material can accept before it breaks. Considering that part of the total potential plastic deformation is used during the forming operation, the ductility will be reduced by work hardening.

Even forming operations that exceed the tensile strength of the local material will have the risk of cracking and breaking. This is a serious material failure. The evidence of this failure can be microscopic or catastrophic.

Microscopic faults are dangerous because they are at risk of being discovered. Although parts with catastrophic failures are not obvious, they can still cause problems because they can cause tool damage. The foreign matter generated by the malfunction or roughness, the malfunctioning part may cause great damage.

As the tensile strength increases, the elongation decreases. Therefore, the tensile strength of the material is considered to be the minimum pressure for all ductility. This consideration is carried out under specific conditions. Pulses of applied force may cause ductility and fracture.

Alloy selection has an impact

Smelters add elements to pure metals to produce alloys. These alloying elements change metal properties, such as corrosion resistance and mechanical properties. For example, chromium is added to steel to form a chromium oxide surface layer that improves corrosion resistance. Nickel is added to affect the formation of austenite crystal phases that can change the strength. The alloy atoms occupy space in the crystal lattice, thus changing the ease with which the atoms can move. In addition, they can change the way grains nucleate and grow, thereby changing the volume of grain boundaries. Changes from these crystallographic changes to atomic motion affect ductility.

Understanding the alloying elements will affect the development of new alloys. Types 301 and 305 stainless steels are good examples of practical applications for ductility. The elongation of type 305 stainless steel in the annealed state is slightly larger than that of 301 stainless steel. In addition, under the same deformation as 301, the total tempering increase of 305 is less. This means that if 305 and 301 deform by the same amount, the yield strength of 305 is lower and the elongation is higher. Under the same deformation, it will start and end with greater ductility.

The ductility after work hardening is an important consideration. More specifically, ductility affects how the final part works.

In one example, if 301 and 305 are bent with equal dimensions, they will eventually have different mechanical properties. This is because they have different ductility and work hardening at different rates, so they end up with different results. In terms of part size, suppose the yield strength of 305 is 150,000 PSI, and the yield strength of 301 is 180,000 PSI. If the equivalent load of this size is 170,000 PSI, the yield strength of 305 has been exceeded, but the yield strength of 301 has not been exceeded. This means that theoretically 305 will yield and deform as a result. That would be a huge problem!

Deep drawing test ductility limit

Deep drawing is an extreme deformation process that can test the limit of ductility. The process needs to have significant ductility in all directions. The raw materials must be produced accordingly.

The deep-drawn material must be properly stretched and ironed to promote the huge movement of atoms. In addition, the raw material must be rolled and annealed first to carefully maintain the ductility of the material in preparation for deep drawing.

The choice of alloy is also crucial. When there are better alloy alternatives, there is no point in trying to design the ductility of the alloy. Similarly, considerations of ductility must be balanced with other required properties (such as corrosion resistance or magnetism).

Deep drawing is an extreme deformation process that can test the limit of ductility. The deep-drawn material must be properly stretched and ironed to promote the huge movement of atoms. In addition, the raw material must be rolled and annealed first to carefully maintain the ductility of the material in preparation for deep drawing.

Other molding processes require different considerations for ductility. For example, stamped parts often need to be bent into the final shape. Plastic deformation causes the atoms to move permanently. Therefore, the final part maintains its curved configuration.

The small metal parts must be bent into a certain shape without breaking, and then their shape must be maintained. This brings a lot of ductility issues. First, the correct alloy with the required ductility must be selected.

Second, a process must be established to promote work hardening of the material. As the bending occurs, atoms will produce defects (dislocations), and these defects will accumulate as the bending progresses. As mentioned earlier, these accumulated defects define the hardening obtained from the bend, thereby increasing the hardness, tensile strength and yield strength of the area. This makes the bending area stronger.

This consideration is critical, because the tempering of the bending directly affects the springback of the bending, and therefore also affects the dimensional control of the part. Although hardness and tensile strength and yield strength increase, elongation decreases. Therefore, the ductility of the work-hardened area decreases.

Therefore, balancing ductility and strength is critical to forming the final part.

Link to this article: What do metal manufacturers need to pay attention to when producing alloys?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

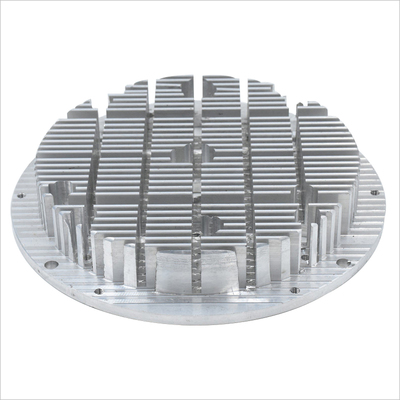

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material