Three factors restrict the development of China's injection mold industry

In recent years, China's injection molds have developed rapidly in terms of quality and quantity. However, compared with foreign advanced technologies, the technical standards of most Chinese enterprises still need to be improved. At present, compared with foreign advanced technology, China's injection mold industry mainly has the following problems.

The contradiction between supply and demand is difficult to solve in the short term. The domestic market satisfaction rate of domestic injection molds has been less than 74%, and the satisfaction rate of large-scale, precise and long-life molds is even lower. At present, the transfer of molds from industrialized developed countries to China is accelerating, and there are more and more international purchases. The market demand is strong, production development is still difficult to keep up for a while, and the situation of short supply will continue for some time.

Unbalanced industrial development Although the products of individual companies have reached or approached the international advanced level, in general, the accuracy, production cycle, service life and other indicators of molds still have a large gap compared with foreign countries, and the overall level of industrial development is low .

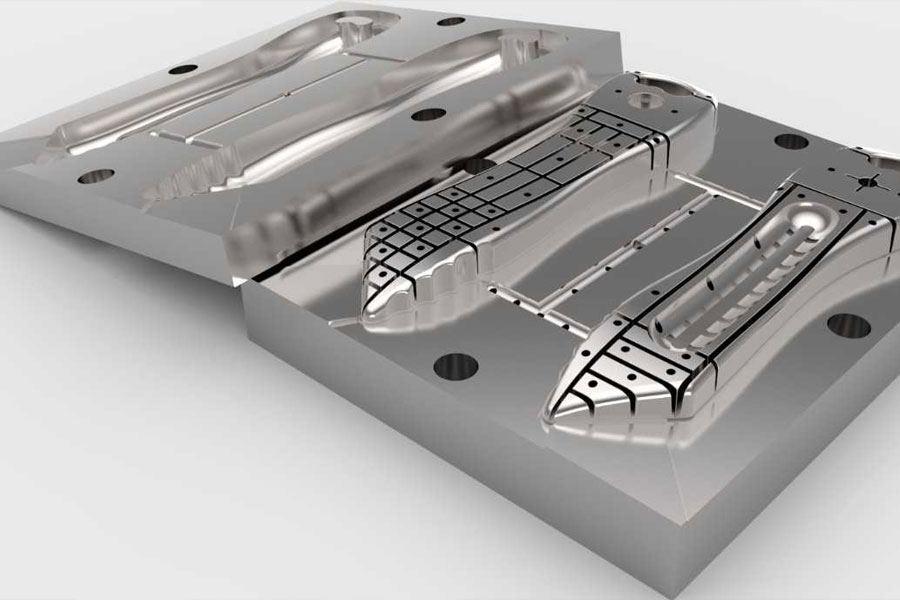

Generally speaking, injection molds are divided into thermosetting plastic molds and thermoplastic plastic molds according to the molding characteristics; according to the molding process, they are divided into transfer molds, blow molds, casting molds, thermoforming molds, and hot press molds (compression molds). ), injection molds, etc. The hot press molds can be divided into three types: overflow, semi-overflow, and non-overflow. The injection molds can be divided into cold runner molds and hot runner molds based on the gating system. ; According to the way of loading and unloading, it can be divided into two types: mobile type and fixed type.

Link to this article:Three factors restrict the development of China's injection mold industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( sales@pintejin.com ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

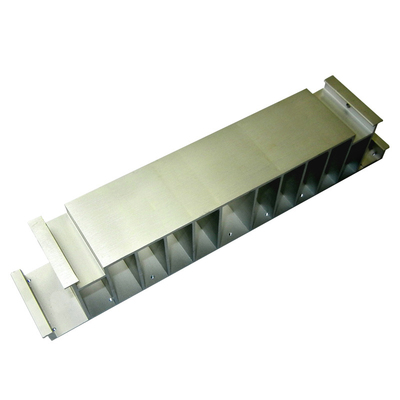

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material